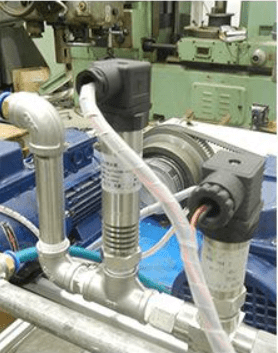

A Silicon Pressure Sensor is a pressure transmitter widely used in industry. It uses diffused silicon or ceramic piezoresistive sensors as pressure detection elements. It has strong overload capacity, good stability, and strong anti-interference ability. It has extremely high accuracy and repeatability, and the measurement interface has good corrosion resistance.

Silicon Pressure Sensor Benefits

Industrial Silicon Pressure Sensor Technical Parameters

| Pressure Media | Fluids, Gas |

| Supply Voltage | -30℃~160-350℃, customized up to -300~850℃ |

| Operating Range | (Gage/Absolute Pressure)–Max(0~60)MPa, Min(0~0.5)KPa |

| (Negative Pressure)—Max(-100KPa~), Min(-0.2~0.2 )KPa | |

| Accuracy | ±0.5%(25℃) |

| Over Pressure | 200% full scale |

| Long Term Stability | <0.25%FS per year |

| Response | <100ms |

| Output Signal | (4~20)mA+HART protocol(Current two-wire/three-wire, HART protocol), etc. |

| Temperature Range | -30℃~160-350℃, Customized up to -300~850℃ |

| Temperature Effects | 0.00015%FS/℃ |

| Pressure Connection | G1/2 female or user specified |

| Electrical Connection | Waterproof Connector(M20*1.5) |

| Protection Class | IP65 |

Silicon Pressure Sensor Applications

Silicon Pressure Sensor Mainly used to measure the pressure of gas, liquid and other objects. The parameters are then converted into standard telecom signals.

The application scope of diffusion silicon pressure transmitter mainly has the following:

- Petroleum/Petrochemical/Chemical

Matched with the throttling device, it provides accurate flow measurement and control.

Measures pressure and level in pipes and tanks. - Electricity/city gas/other company business

Places such as measurement require high stability and high precision. - Pulp and paper

It is used in places requiring chemical resistance, corrosion resistance, etc. - Steel/non-ferrous metals/ceramics

It is used for furnace pressure measurement and other places requiring high stability and high precision measurement.

For use where stable measurements are required under strictly controlled (temperature, humidity, etc.) conditions. - Machinery/Shipbuilding

It is used in places where stable measurement is required under high-precision conditions such as strict control of temperature and humidity.

Extended reading: Featured Diaphragm Seal Pressure Transmitters

More Pressure Measurement Solutions

- Small Pressure Transducer/Sensor-Low Cost-High Performance

- What’s the Difference Between a Pressure Transducer and a Pressure Switch?

- What Is Flush Diaphragm Pressure Transducer? When Use?

- Natural Gas Pipeline Monitoring: Pressure-Temperature-Flow

- Different Types of Pressure: Absolute, Gauge, Sealed Gauge and Differential Pressure

- Static Pressure Sensor and Transmitter Features and Applications

- Pressure indicator transmitters

- How Does a Pressure Transmitter Work?

- Pressure Transmitter Calibration

- SMART HART Pressure Transmitter

All of our pressure sensors can work with the NEW AMS TERX communicator.

Sino-Inst offers over 20 Silicon Pressure Sensors. A wide variety of Silicon Pressure Sensors options are available to you. Such as free samples, paid samples. Sino-Instrument is a globally recognized manufacturer of Silicon Pressure Sensors, located in China.

Sino-Inst sells through a mature distribution network that reaches all 30 countries worldwide. Silicon Pressure Sensors products are most popular in Europe, Southeast Asia, and Mid East. You can ensure product safety by selecting from certified suppliers. With ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.