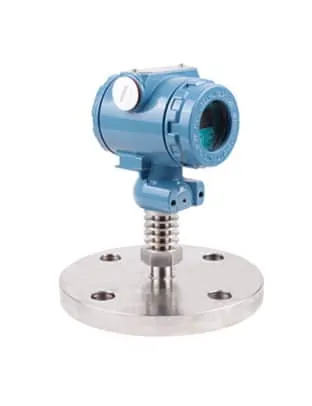

Flange Mounted Differential Pressure Transmitter can be directly installed on the pipe or tank. Based on an ordinary pressure/differential pressure transmitter, a Flush flange or extended flange is added. It can be used for differential pressure measurement and liquid level measurement.

Mainly used to measure high temperature, easy to solidify or crystallize, containing suspended solids, too viscous, corrosive or other media that need to maintain sanitary conditions and cannot be contaminated.

Sino-Inst offers a variety of flange-mounted DP transmitters for industrial pressure measurement. If you have any questions, please contact our sales engineers.

Sino-Inst Flange Mounted Differential Pressure Transmitter uses advanced microprocessing technology and digital communication technology. It outputs a 4 to 20 mA DC signal corresponding to the measured differential pressure. It can also be configured with the HART protocol.

SMT3151LT Flange Mounted Differential Pressure Transmitter can replace EJA210E. It is a functional replacement for Rosemount 3051 and Yokogawa EJA.

Extended reading: How to calibrate HART pressure transmitters

Flange Mounted Differential Pressure Transmitter Features:

Extended reading: Smart Differential Pressure Transmitter

Specification of Flange Mounted Differential Pressure Transmitter

| Model | Transmitter type | |||

| SMT3151LT | Flange liquid level transmitter | |||

| Code | Scale range | |||

| 4 | 0-4.0~40kPa(0-400~4000mmH2O) | |||

| 5 | 0-20~200kPa(0-2~20mH2O) | |||

| 6 | 0-70~700kPa(0-7~70mH2O) | |||

| 7 | 0-210~2100kPa(0-21~mH2O) | |||

| Code | Output form | |||

| E | Linear output 4-20mAdc | |||

| SF | Linear output 4-20mAdc +HART signal | |||

| F | MODBUS-485 signal | |||

| Code | Flange standard (high pressure side flange) | |||

| A | ANSI American Standard (HG20615) | |||

| D | DIN European Standard (HG20592) | |||

| Code | Process connection size | |||

| ANSI American Standard (HG20615) | DIN European Standard (HG20592) | |||

| 25 | 1” | DN25 | ||

| 40 | 1.5” | DN40 | ||

| 50 | 2” | DN50 | ||

| 80 | 3” | DN80 | ||

| 0 | 4” | DN100 | ||

| Code | Process connection pressure rating | |||

| ANSI American Standard (HG20615) | DIN European Standard (HG20592) | |||

| A | 150LB | PN16/25 | ||

| B | 300LB | PN40 | ||

| C | 600LB | PN64 | ||

| D | 900LB | PN100 | ||

| Code | High pressure side diaphragm | |||

| A | 316 stainless steel | |||

| B | Hastelloy C | |||

| C | Monel | |||

| D | Tantalum | |||

| E | Titanium | |||

| F | Special Requirements | |||

| Code | High pressure side insert tube length | High pressure side insert cylinder material | ||

| A | 0 mm | None | ||

| B | 50 mm | 316L Stainless steel | ||

| C | 150 mm | 316L Stainless steel | ||

| D | 200 mm | 316L Stainless steel | ||

| Code | High pressure side filling fluid | |||

| D | General silicone oil (-40~104℃) | |||

| F | High temperature silicone oil (-40~304℃) | |||

| S | Inert liquid (-40~204℃) | |||

| Low pressure side structural material | Flange (joint) | Exhaust/drain valve | Isolation diaphragm | Sensor filling fluid |

| 22 | 316 Stainless steel | 316 Stainless steel | 316 Stainless steel | Silicone oil |

| 23 | 316 Stainless steel | 316 Stainless steel | Hastelloy C | Silicone oil |

| 24 | 316 Stainless steel | 316 Stainless steel | Monel | Silicone oil |

| 25 | 316 Stainless steel | 316 Stainless steel | Tantalum | Silicone oil |

| 33 | Hastelloy C | Hastelloy C | Hastelloy C | Silicone oil |

| 35 | Hastelloy C | Hastelloy C | Tantalum | Silicone oil |

| 44 | Monel | Monel | Monel | Silicone oil |

| S2 | A remote transmission device (with a remote transmission device on the low-voltage side) | |||

| Code | Shell material | Conduit inlet dimensions | ||

| A | Low copper aluminum alloy polyurethane coating | M20×1.5 | ||

| B | Low copper aluminum alloy polyurethane coating | 1/2-14 NPT | ||

| C | Stainless steel | M20×1.5 | ||

| D | Stainless steel | 1/2-14 NPT | ||

| Code | Optional parts | |||

| M1 | 0~100% Linear indicator head | |||

| M4 | LCD multi – power digital display head | |||

| D1 | Side discharge valve at the top (only for the low pressure side of the low pressure side without remote transmission) | |||

| D2 | Side discharge valve at the top (only for the low pressure side of the low pressure side without remote transmission) | |||

| Da | Flameproof ExdIIBT5Gb;(explosion-proof certificate no. : CE16.1163) | |||

| Fa | Intrinsically safe ExiaIICT4 / T5 / T6Ga;(explosion-proof certificate no. : CE15.2354X) | |||

| CX | With corresponding 316 flushing ring |

Extended Reading:

Applications

The single-flange pressure/level transmitter can accurately measure the liquid level and density of various containers. There are two types of flat flange and plug-in flange. It is suitable for high-viscosity medium or suspended liquid measurement.

- Viscous medium at high temperature;

- Easily crystallized medium;

- Precipitation medium with solid particles or suspended matter;

- Strongly corrosive or highly toxic medium;

- It can eliminate the leakage of the pressure guiding pipe and pollute the surrounding environment. It can avoid the instability of the measurement signal when the isolation liquid is used. The tedious work of frequently supplementing the isolation liquid is required;

- Continuously and accurately measure the interface and density;

- The remote transmission device can avoid the mixing of different instantaneous media so that the measurement results truly reflect the actual situation of process changes;

- Places with high sanitation requirements;

- Such as in the production of food, beverage, and pharmaceutical industries. Not only the transmitter contacting the media parts meet hygienic standards, but also should be easy to wash. To prevent cross-contamination of different batches of media.

Pressure level transmitter is good for level measurement. Most of the time, we use submersible hydrostatic level sensor for the level measurement. When you can not use the probe of hydrostatic level sensor, you can try with this pressure level transmitter. Pressure level transmitter, is one type of DP level measure instrument, with the diaphragm.

SMT3151LT Differential pressure (DP) level transmitter a new type of differential pressure (DP) transmitter produced by advanced technology and equipment. Continuous level, flow and differential pressure measurement. Liquid level measurement, is the most common measurement process in continuous production processes, such as: petroleum and chemical industry. The liquid level measuring instrument currently widely used, is the differential pressure level transmitter.

Flange Mounted Differential Pressure Transmitter Working principle

The Flange Mounted Differential Pressure Transmitter is directly mounted on the reserved flange at the bottom of the pipeline or container. It contacts the liquid through the isolation diaphragm.

When the diaphragm is pressurized, it will produce a slight deformation. The displacement of the diaphragm will move with the change of the differential pressure. This change is accurately converted into a 4-20mA DC two-wire current, voltage or digital HART output signal by the amplifier circuit to achieve pressure measurement and transmission.

You may like: differential pressure transmitter working principle|Working Principle of pressure level transmitters| differential pressure level transmitter working principle

Single flange. VS. Double flanges differential pressure level transmitter

- In principle: all are differential pressure transmitters + flange guide pressure;

- In terms of structure: the single flange liquid zd position transmitter has only one flange diaphragm box connected to the high pressure side, and the low pressure side to the atmosphere. The double flange liquid level transmitter is high and low pressure side through oil-filled capillary It is connected with two flanged membrane return boxes. There is also a capillary. The single flange transmitter is installed below, and a capillary is drawn from the low pressure side of the single flange transmitter to the upper flange membrane box.

- In terms of engineering applications: all can only measure the liquid level of fixed density. The single-flange transmitter can only be used for the liquid level of atmospheric equipment that can be imagined with the atmosphere. The double-flange transmitter can be suitable. Answer: Use closed equipment kettle to measure liquid level;

- From the economical point of view, the double flange is definitely more expensive than the single flange. After all, there is one more flange capsule and capillary.

How to choose flange type level transmitter?

Flange-level transmitters often require special environmental processing during production. Requires small range and high accuracy. Flange-level transmitters are also required to withstand high temperatures, corrosion resistance, and high overload withstand capability. Therefore, the scope of application must be clearly defined when selecting the flange type liquid level transmitter.

When choosing a flange-type liquid level transmitter, the following factors are mainly considered:

- The measurement object, such as the physical and chemical properties of the measured medium. And working pressure and temperature, installation conditions, speed of liquid level change, etc .;

- Measurement and control requirements. Such as measurement range, measurement accuracy, and display method. On-site instructions, long-distance instructions, interface with computer, safety and anti-corrosion. Reliability and construction convenience.

When selecting a double-flange differential pressure transmitter, a very important factor must be paid attention to is the differential pressure level transmitter. It is installed at the bottom of the liquid container. The height of the liquid level is reflected by the gauge pressure signal. In the control process of liquid level measurement in the pharmaceutical and chemical industries. The container holding the liquid is often under pressure. At this time, the conventional static pressure liquid level transmitter cannot meet the measurement requirements. Due to improvements in the sensor circuit and structure. Improve the practical value of differential pressure liquid level measurement technology in the pharmaceutical and food industries.

Piezoresistive Differential Pressure Transmitter utilizes the piezoresistive effect of semiconductor silicon materials. Realize accurate measurement of differential pressure.

Smart Differential Pressure Transmitter measures industrial differential pressure. Can Works with diaphragm seals, capillary, HART. Outputs standard signals (such as 4 ~ 20mA, 0 ~ 5V).

When the process medium should not come into contact with the pressured parts of the measuring instrument. Diaphragm sealed pressure transmitters are used for pressure measurement.

High-temperature pressure transmitters with a 4-20mA output.

which has a temperature capability of over 850 °C and is not pyroelectric.

More Pressure and Level Measurement Solutions

- Optimize Filtration Monitoring with Differential Pressure Sensors

- Low Cost Differential Pressure Sensor – Solve Big Problems!

- Oxygen Cleaning Pressure Sensor – No Oil, No Corrosion, No Impurities

- Voltage Pressure Transducer Comparison

- What Is a Differential Pressure Sensor?

- Different Types of Pressure: Absolute, Gauge, Sealed Gauge and Differential Pressure

- Use Differential Pressure Transmitter to Measure Liquid Level

Sino-Inst is one of the most excellent DP transmitters, pressure transmitters, and level transmitters suppliers. Sino-Inst can offer you a complete solution for pressure transmitters.

Sino-Inst can offer you with Flange Mounted Differential Pressure Transmitter. Our transmitters can work for you just like EJA210E.

Our Flange Mounted Differential Pressure Transmitters are widely exported to various countries. Including USA, UK, Argentina, Singapore, etc. If you need to purchase Flange Mounted Differential Pressure Transmitter, or have related technical questions, please feel free to contact our sales engineers!

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.