Different Types of Pressure have different characteristics. Different pressure transmitters bear different pressure types. Common pressure types include absolute pressure, gauge pressure, negative pressure or vacuum, and differential pressure.

Each type of pressure works and causes differently. Therefore, when selecting, installing and using pressure transmitters, different types of pressure transmitters should be selected according to the specific pressure. At the same time, when measuring, it is necessary to have a detailed understanding of the specific specifications of the pressure transmitter.

Different Types of Pressure

Read more about: Absolute Pressure Vs Gauge Pressure Measuring Instruments

Applications of Different Types of Pressure

So what are the practical applications of these pressures?

Gauge pressure is usually used to measure without considering the influence of atmospheric pressure. For example, gauge pressure sensors are used in submersible liquid level transmitters.

Absolute pressure is just the opposite. Because its reference point is vacuum pressure. Many customers will choose absolute pressure sensors when measuring pipeline pressure.

Sealed gauge pressure is rarely used in practical applications. For diffused silicon pressure sensors, some customers will choose sealed gauge pressure in the scene of high humidity measurement. The purpose is to prevent water vapor from entering from the air hole behind the pressure core Pressure chip. This causes the instability of the output of the pressure chip. The failure phenomenon that often occurs in the use of sealed gauge pressure is that if there is a large difference between the atmospheric pressure at the sensor calibration location and the sensor user’s use location, the zero output of the sensor will appear A certain deviation. As a result, the accuracy deteriorates.

Differential pressure measures the difference between two pressures. So many customers use differential pressure to measure flow.

How to choose the pressure type?

Like temperature and Flow, pressure is one of the most important physical state variables. The different types of pressure are mainly distinguished based on the reference pressure. When measuring the pressure of liquid or gaseous media, the pressure type and pressure range are important factors for pressure transmitters.

Pressure range: such as ≤0.02MPa, ≥3.5MPa, 0.035MPa~3.5MPa.

Pressure type: gauge pressure, sealed gauge pressure, absolute pressure, gauge pressure, absolute pressure.

In layman’s terms, ordinary pressure gauges measure gauge pressure. Adding atmospheric pressure is absolute pressure, and there is a special absolute pressure gauge for measuring absolute pressure.

The pressure is taken at two different locations on the pipeline, and the difference between the two pressures is the differential pressure. The general differential pressure transmitter is to measure the differential pressure.

The sealing pressure is a pressure that is sealed in the back pressure chamber of the sensor as a reference pressure.

As atmospheric pressure may vary with location, weather and altitude. Therefore specific applications require different pressure types.

Whether it is absolute pressure, gauge pressure or differential pressure. If you are not sure which to choose. Our experienced and professional sales engineers are happy to assist you.

Read more about: What is Diaphragm pressure gauge?

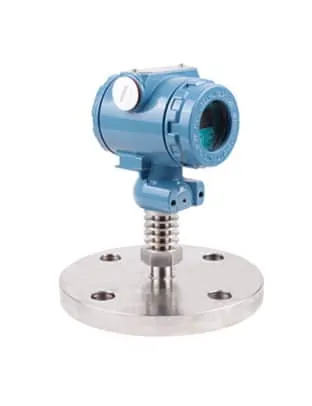

Different Types of Pressure Transmitters

The pressure transmitter is the so-called universal gauge pressure transmitter. One side is open to the atmosphere and the other side is connected to the measured pressure. It is used to measure the pressure of pipelines, boilers, etc. The pressure transmitter has only one impulse tube and measures pure pressure.

The differential pressure transmitter has two pressure pipes and measures the pressure difference. If the differential pressure transmitter is only connected to the positive membrane chamber or the negative membrane chamber, it is equivalent to the measurement of the pressure transmitter. The two sides of the differential pressure transmitter are respectively connected to different pressures. Measure the height of the liquid level according to the pressure difference and cooperate with the orifice plate to measure the flow of the pipeline.

One side of the absolute pressure transmitter is evacuated, and the pressure on the other side is absolute pressure. Suitable for absolute pressure applications.

The Micro differential pressure transmitter uses 2E capsule (0.0-1.5KPA) to improve the accuracy of measuring small pressure.

The high static pressure differential pressure transmitter uses a high static pressure capsule. The so-called static pressure means that when the pressure on both sides of the pressure transmitter is the same, its output current should be 4.00MA. However, when the pressure on both sides of the ordinary differential pressure transmitter increases to more than 25MPA at the same time, it is difficult to guarantee the output at 4.00MA. Therefore, high static pressure differential pressure transmitters are mostly used for flow, liquid level measurement and high pressure occasions.

What else can a pressure transmitter measure?

Liquid Level

Pressure transmitters and differential pressure transmitters measure pressure and differential pressure (the difference between the two pressures) by name. But they can be measured indirectly by a lot. In addition to measuring pressure, it can also measure the liquid level in the equipment.

When measuring the liquid level in an atmospheric pressure vessel, a pressure transmitter is all that is needed.

When measuring the liquid level of a pressure vessel, consider using two pressure/differential pressure transmitters. That is, one set for the lower limit of measurement and one set for the upper limit of measurement. They have to output signals for subtraction. The liquid level can be measured.

Density

It can also be used to measure the density of the medium when the liquid level and pressure in the container do not change.

Flow

The measuring range of the pressure transmitter can be made very wide. Starting from absolute pressure 0, it can reach more than 100 MPa (general situation). In addition to measuring the differential pressure value of the two measured pressures, the differential pressure transmitter. It can also cooperate with various throttling components to measure the flow rate of medium fluid.

Read More about: Pressure Sensor Applications In Various Industries

More Featured Pressure Measurement Solutions

Sino-Inst is a manufacturer of Different Types of Pressure Transmitters. We supply more than 50 types of Differential Pressure Transmitters. 30% are gauge pressure transmitters, 30% are differential pressure transmitters, and the rest are absolute pressure and other types pressure transmitter.

The concept of differential types of pressure is involved in the selection of pressure transmitters: absolute pressure, gauge pressure, negative pressure and differential pressure.

Although their explanations are somewhat difficult to understand, the principle is actually very simple. You only need to know this, the principle of these four pressure transmitters is the principle of differential pressure. That is, one side is connected to the medium pressure, and the other side is the reference pressure. The only difference is the pressure at the connection on the reference pressure side.

Sino-Inst has provided Different Types of Pressure measurement solutions to customers for many years. Our Different Types of Pressure Transmitters, made in China. Widely exported to the United States, Britain, Germany, South Africa, Norway and other countries.

If you need Different Types of Pressure Transmitters, but have technical questions, please feel free to contact our sales engineers.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.