Magnetostrictive liquid level sensor can be used as a fuel tank level sensor. With LCD digital display. Perfect choice for Continuous Level measurement of the diesel tank/fuel tank.

Magnetostrictive liquid level sensor is a Digital display head type liquid level sensor. Specially designed for applications with on-site digital display requirements. Reliable measurement of continuous liquid level and interface are provided in tank level measurement. The LT Level sensors with a magnetostrictive measuring principle support 4-20mA, fieldbus output. Easy installation for storage tank, like Fuel storage tank (explosion proof ).

- Digital display head, on-site display liquid level.

- Support: Analog output, Modbus output (optional)

- Explosion protection: Exd II B T5 (optional)

Sino-Inst offers a variety of magnetostrictive liquid level sensor for industrial level measurement. If you have any questions, please contact our sales engineers.

Need Level Indicator for CO2 tank? Learn more here.

Features of Magnetostrictive liquid level sensor

The LT series digital display head type liquid level sensor is specially designed for the application with on-site digital display requirements. For large-range liquid level measurement (5-22 meters), a flexible measuring rod can be selected. This avoids the difficulties of installation and transportation caused by a large range.

The sensor can be installed on the top of the tank directly (threaded) or through the flange. The flange is equipped with a mounting position adjustment device. The sensor can be adjusted within a certain range.

The flexible measuring rod is equipped with a translucent anti-corrosion sheath on the outside to enhance the product’s resistance in corrosive environments. The product adopts flameproof enclosure (explosion-proof mark: Ex d II B T5). It has more advantages in the detection of liquid level in hazardous environment.

- Built-in digital display head for easy observation of liquid level data;

- Absolute output without regular calibration and maintenance;

- Zero / full-scale point can be adjusted arbitrarily;

- Low power consumption design, effectively reducing system temperature drift;

- High precision, maximum 0.1mm level measurement accuracy;

- Side outlet for easy installation;

- Optional ultra-long range, up to 22m

Applications of Magnetostrictive liquid level sensor

- Sensor for continuous level measurement of liquids in bypass level indicators

- Chemical and petrochemical industries, offshore

- Shipbuilding, machine building

- Power generating equipment, power plants

- Pharmaceutical, food, water treatment, environmental engineering industries

- Simultaneous Measurement of Multiple Process Conditions:

- -Product Level

- -Interface Level

- -Temperature

- -Volume

Industries served:

- Oil and Gas

- Petrochemical

- Chemical

- Power Generation

- Water and wastewater treatment

- Pulp and Paper

- Biotech

- Marine

- Aerospace

Learn more about Diesel fuel tank level gauges & Indicators

TechSpecifications of LT series Magnetostrictive liquid level sensor

| Item | Parameters |

| Analog output | Current: 4-20mA (minimum / maximum load: 0-500Ω) Voltage: 0-10V (minimum load> 5KΩ) Resolution: 16-bit D / A |

| Modbus | Output signal: Modbus RTU |

| Output | Transmission rate: 9600bps by default, 19200 / 4800bps optional Resolution: 0.01mm |

| Measurement parameters | |

| Hard measuring rod | 100-5000mm |

| Flexible measuring rod | 5000-22000mm |

| Non-linearity | <± 0.05% of full scale F.S. |

| Repeatability | <± 0.02% F.S. of full scale |

| Update frequency | 10 Hz by default, frequency can be customized |

| Electrical characteristics | |

| Outlet method | Straight out of the cable |

| Input voltage | 24VDC (-15 / + 20%) |

| Working current | <60mA (varies with range) |

| Polarity protection | -30VDC |

| Overpressure protection | 36VDC |

| Insulation capacity | 500V (between signal ground and case) |

| Working conditions | |

| Ambient temperature | -40 ~ 85 ℃ |

| Humidity / zero | 90% humidity, no condensation |

| Humidity coefficient | <50ppm / ℃ |

| Protection class | IP68 |

| Explosion-proof | ExdIIBT5 |

| Installation & accessories | |

| Installation method | M18 * 1.5 thread, matching flange (optional) |

| Stylus structure | Rigid / flexible rod, 304L stainless steel, optional Teflon coating |

| Electronic warehouse | Anodized aluminum alloy |

| Float | 304L stainless steel, optional Teflon coating |

Extended reading: Types of Fuel-Diesel Level Sensors

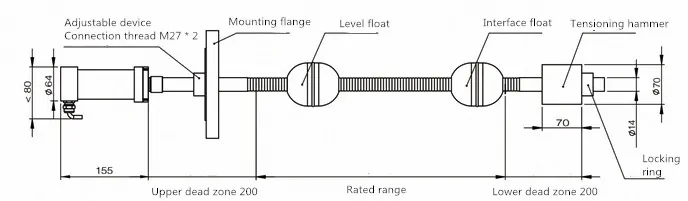

Dimensions

Note 1: Different floats have different measurement blind spots at the first and last measurement ends. Please consult technical support before ordering.

Note 2: The outside diameter of the rod without temperature measurement is 10mm, and the outside diameter of the rod with temperature measurement is 12mm.

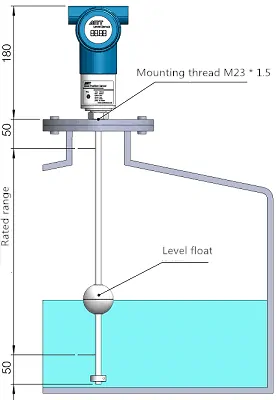

Magnetostrictive liquid level sensor Installation on Tank

LT series digital display head type liquid level sensor can provide two types of installation: rigid measuring rod and flexible measuring rod. The maximum range can reach 22 meters. There is a Teflon protective sleeve on the outside of the measuring rod. The sensor is mounted on the ceiling through the flange. The flange is equipped with an installation position adjustment device, which can adjust the range of the sensor within a certain range. There are measurement blind areas at the beginning and end of the sensor, which need to be considered during installation.

The sensor uses low-voltage DC power supply, which is more secure in the detection of dangerous goods storage.

Application of Magnetostrictive Liquid Level Senor in Storage Tank

Liquefied petroleum gas is one of the most widely used fuels in civil and industrial production. During the storage and transportation of liquefied petroleum gas, liquid level measurement is an important task of the project. It is required not only to have high accuracy for liquid level measurement. It must also be able to adapt well to the working conditions of closed pressure vessels. At the same time, in order to meet the needs of remote monitoring and management. It must also require the measurement data to have the function of long-distance transmission.

At present, the comparison of the common detection methods for the storage tank liquid level in the tank area is as follows:

| Instrument name | Accuracy | Measuring principle | Liquid level, interface, temperature measurement | Regular maintenance | On-site installation | overall costs | Service life |

|---|---|---|---|---|---|---|---|

| Magnetostrictive liquid level sensor | 0.5mm | Magnetostriction | Yes (integrated) | Maintenance-free | Simple | Low | 20 years |

| Servo level sensor | 1mm | mechanical | Yes (split) | Regular maintenance | Complicated | High | short |

| Guided wave radar level senosr | 1mm | Radar | no | Maintenance | Complicated | High | Longer |

Extended reading: Non contact level measurement

Advantages of stainless steel magnetostrictive liquid level sensor for oil level measurement:

- High precision: the magnetostrictive liquid level gauge uses waveguide pulse to work. During the work, the measured displacement is determined by measuring the time of the start pulse and the end pulse. Therefore, its measurement accuracy is high. The resolution is better than 0.01% FS. This is an accuracy that is difficult to achieve with other sensors.

- Good safety: the magnetostrictive liquid level gauge has high explosion-proof performance. Safer to use. Especially suitable for the measurement of chemical raw materials and flammable liquids. There is no need to open the tank lid during measurement, and there is no insecurity for manual measurement.

- Strong reliability: Because the magnetostrictive liquid level gauge uses the waveguide principle. There are no mechanical moving parts, so there is no friction and no wear. The entire converter is enclosed in a stainless steel tube and does not contact the measuring medium. The sensor works more reliably and has a longer life.

- Facilitate system automation: The secondary instrument of the magnetostrictive liquid level gauge adopts standard output signal. Help the computer to process the signal. It is easy to work on the Internet. Improve the automation of the entire measurement system.

- Simple installation and maintenance: the magnetostrictive liquid level gauge is usually installed through the existing nozzle on the tank top. It is especially suitable for the installation of underground storage tanks and already put into operation. And will not affect normal production during the installation process.

If you need to measure river water level, open channel level, etc. The Ultrasonic Liquid Level Sensor can be used for non-contact continuous level monitoring. Extended reading: Ultrasonic level transmitter for Hazardous Liquids

What is magnetostrictive level transmitter?

Magnetostrictive liquid level transmitter is a kind of liquid level sensor. But it uses the principle of magnetostrictive operation internally. And combines modern electronic technology to measure the time value between pulse waves to achieve the purpose of accurately measuring the liquid level . The magnetostrictive liquid level meter works with waveguide pulses. During the work, the measured displacement is determined by measuring the time of the start pulse and the end pulse, so the measurement accuracy is high.

How does a magnetostrictive sensor work?

- The device electronics generates a low energy current pulse at fixed intervals.

- The electrical pulses create a magnetic field which travels down a specialized wire inside the sensor tube.

- The interaction of the magnetic field around the wire and the magnetic float causes a torsional stress wave to be induced in the wire. This torsion propagates along the wire at a known velocity, from the position of the magnetic float and toward both ends of the wire.

- A patented sensing element placed in the transmitter assembly converts the received mechanical torsion into an electrical return pulse.

- The microprocessor-based electronics measures the elapsed time between the start and return pulses (Time of Flight). And converts it into a position measure-ment which is proportional to the level of the float.

Extended reading: Radar Level Sensor Working Principle

Magnetostrictive level transmitter price

The price of a magnetostrictive level transmitter is determined based on the measurement conditions. Sino-Instrument is a manufacturer of magnetostrictive level gauges. We offer magnetostrictive level gauges at the right price.

Selection considerations:

1. The selection of the level gauge should be consistent with the environment of the media on the site. Including ambient temperature, pressure, vibration, shock, compatibility of structural materials and media, etc.

2. When the temperature of the measured medium is high (100 ~ 200), it is recommended to choose a probe with an outer float type and use a side flange installation. When the temperature is higher (200 ~ 300), it is recommended to choose a probe with a side-bundled type with an outer float, and install it with a side flange.

3. There are measurement dead zones at the upper and lower ends of the measuring rod of the magnetostrictive level gauge, which should be considered when selecting the range.

4. The size of the stainless steel magnetic float commonly used for level gauges is Ф45 × 56 × Ф15, and flange connection of DN50 or above is required. For the liquid level gauge with thread connection, users need to install flange or bracket.

Magnetostrictive liquid level sensor can measure liquid level or interface. However, it is not possible to perform on-off control of the liquid level. If you need to control the tank level, you can read Guide for Liquid level float switches.

FAQ

How does a level transmitter work?

The level of the liquid medium in the container is called the liquid level. And the instrument that measures the liquid level is called the liquid level transmitter. Level transmitter is a kind of level instrument. There are two types of level transmitterss, one is continuous and the other is point-off. The continuous level transmitter is a real-time monitor of the height of the liquid in the container. The point type, which generally takes two points, high and low, and outputs an alarm signal when the medium in the container reaches these two points.The types of liquid level transmitters is very wide. Specific include: magnetic flap liquid level gauge, tuning fork vibration type, differential pressure type, pressure type. Ultrasonic, magnetostrictive liquid level gauge, magnetic flap, radar and so on.

Levels of media such as: water, viscous fluids, and fuels, or dry media such as bulk solids and powders can be measured using the transmitter.

Level measurement transmitter are used in a myriad of applications that require level measurement within containers or tanks. These transmitters often find their application in material handling, food and beverage, power, chemical, and water treatment industries.

Learn More

How does a hydrostatic level sensor work?

When considering a new level sensor for level measurement applications,

it is often hard to find information on how the different types of level sensors,

like the hydrostatic level sensors respectively hydrostatic pressure sensors, are working.

Recently, I explained level measurement by using the hydrostatic pressure measurement.

In closed geometries, such as enclosed tanks and vessels,

generally, flush pressure sensors or pressure transmitters are used,

which can be screwed into the vessel from the outside.

Pressure sensors are therefore particularly suitable,

in applications of free-standing tanks and vessels.

A submersible pressure transducer

or a flush pressure sensor

measures the height-dependent weight-force of the liquid column,

also known as hydrostatic pressure.

This pressure measurement is directly proportional to the liquid level respectively liquid column,

at the measuring point of the pressure sensor.

It is, therefore, necessary, for the measurement of level,

that the pressure sensor is placed as close as possible to the level of the vessel’s bottom.

The measured hydrostatic pressure then directly corresponds to the height of the liquid column,

from the ground-level measurement point to the surface-level of the medium.

So, the filling height is calculated from the distance of the medium surface,

to the measuring point by the pressure measurement.

The weight force of the liquid column,

thus the hydrostatic pressure, however,

is not only directly proportional to the filling height

but also varies with the specific gravity of the medium and the force of gravity.

More

Extended reading: Hydrostatic Level Measurement

What is DP type level transmitter?

The liquid level (pressure/differential pressure) transmitter is a pressure signal,

measured at the reference side of atmospheric pressure (low pressure side),

with one or two ports for flange (or other connection) and process pipe connection.

On the basis of common pressure/differential pressure transmitter,

one or two isolation membrane boxes, are added to measure the liquid receiving part.

Mainly used for measuring high temperature, easy to solidify or crystallize,

containing solid suspended matter, too viscous,

corrosive or other needs to maintain sanitary conditions, non-polluting media.

More

Read more about : Diesel Fuel Level Sensor Types

More Featured Level Senors

Featured Continuous level sensors

Sino-Instrument offers over 10 level transmitters for level measurement. About 50% of these are liquid level meters, 40% is the tank level sensor.

A wide variety of level meters options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of level measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.