High pressure transducer is used to measure high pressure up to 1500Mpa. Also called ultra high pressure transducer.

High pressure transducer adopts ultra high pressure design. Suitable for high pressure applications up to 15000bar. SI-702S series ultra high pressure pressure transducer can provide reliable ultra-high pressure measurement. Ultra high pressure transmitter adopts rare metal alloy material. After special process treatment, integrated design. All stainless steel welding package. Laser resistance temperature compensation. With high performance digital processing circuit. The factory has undergone high and low temperature aging and long-term fatigue tests. Good long-term stability. Ultra-long working life. Maintain safe and stable operation in the ultra-high pressure range.

Sino-Inst offers a variety of High pressure transducers for industrial pressure measurement. If you have any questions, please contact our sales engineers.

More High Pressure Transducers:

Features of SI-702s High pressure transducer

- Pressure range: 0-1500MPa …. 0-2000MPa to 0-7000MPa (customized)

- Accuracy level: 0.1% FS, 0.2% FS, 0.5% FS

- All stainless steel structure

- Internally generated calibration signal

- Using high-voltage accessories

- Protection class IP65

Maybe you just need high pressure pressure sensor: 0 ~ 40MPa… 600MPa.

Specifications of High pressure transducer

| Pressure range: | 0-1500MPa …. 0-2000MPa to 0-7000MPa (customized) |

| Comprehensive accuracy: | 0.1% FS, 0.2% FS, 0.5% FS |

| Output signal: | 4-20mA ( 2 wire system), 0-5 / 1-5 / 0-10VDC (3 wire system) |

| Power supply voltage: | 24VDC (10-30VDC) |

| Medium temperature: | -20 ~ 75 ℃ |

| Ambient temperature: | -20 ~ 75 ℃ |

| Load resistance: | Current output type: max. 800Ω; Voltage output type: greater than 50KΩ |

| Insulation resistance: | Greater than 2000MΩ (100VDC |

| Sealing grade: | IP65 |

| Long-term stable performance: | 0.1% FS / year |

| Vibration effect: | Within the mechanical vibration frequency of 20Hz ~ 1000Hz, the output change is less than 0.1% FS |

| Electrical interface: | Four-core aviation connector, Hessman connector optional |

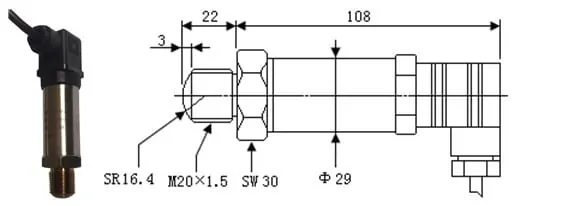

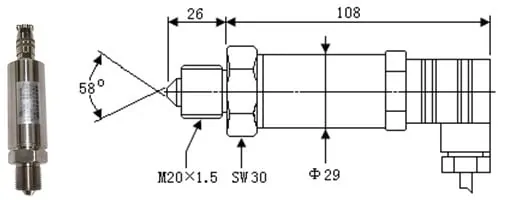

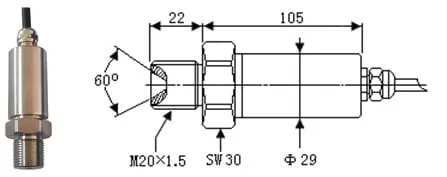

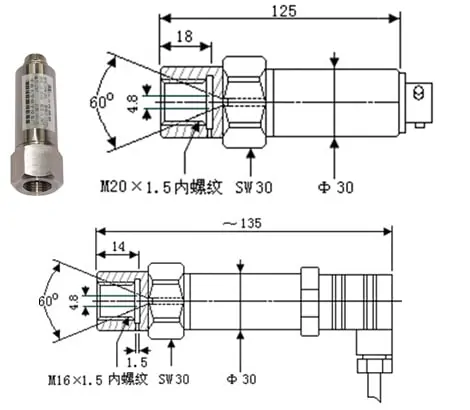

| Thread interface: | Ball head M20 × 1.5, cone head M20 × 1.5, M22 × 1.5, etc. Other threads can be designed according to customer requirements. |

Ultra high pressure quick connector-1 / 4NPT 3 / 8NPT high pressure connector

Features: High-strength carbon steel. Galvanized surface treatment. Check valves at both ends. Steel ball lock. Interchangeable with ENERPAC / parker3000.

Thread: 1 / 4NPT. 3 / 8NPT

Working temperature: -30-100 ℃

Maximum working pressure: 10000psi (700bar)

Features: High-strength carbon steel, galvanized surface, check valves at both ends, steel ball lock, 2 times safety factor.

Product description: The HP high-pressure series is designed for use in high-pressure environments. All metal parts are made of steel. The base of the female connector is treated by QPQ. The base of the male connector is treated by all black galvanizing.

SI-702s High pressure transducers types

SI-702Q Ultra High pressure transducer adopts spherical sealing method. It can choose 0-20mV, 4-20mA, 0-5VDC output. The ultra-high pressure pressure transmitter uses fully integrated rare alloy materials. Fine machining. Multiple heat treatment processes. Each sensor undergoes rigorous pressure testing to ensure absolute safety and reliability. The sensor has high accuracy, long-term stability, and long life specialty.

SI-702Z Ultra High pressure transducer is an extended product of 702S. It is characterized by a 58 degree outer cone seal. The ultra-high pressure structure and processing technology ensure the long-term reliability of the product. High accuracy, long life, and various electrical interfaces to choose from.

SI-702W Ultra High pressure transducer, M20 × 1.5 external thread with 60 degree inner cone seal. Fine machining, multiple heat treatment processes. Each sensor undergoes rigorous pressure test and high and low temperature aging. It guarantees absolute safety and reliability. The sensor has the characteristics of high accuracy, good stability and long life. Various electrical interfaces are available.

SI-702N Ultra High pressure transducer, M20 × 1.5 internal thread with 60 degree inner cone sealing method. Each sensor has undergone strict pressure test and aging. It guarantees absolute safety and reliability. It has high accuracy, long-term stability and long life. Features. A variety of shapes can be selected and a variety of electrical interfaces can be selected.

Applications of SI-702S Ultra High pressure transducer

SI-702S Ultra-High Pressure Transducer is designed for high pressure hydraulic circuit applications. The electronic components with excellent stability are selected and the voltage and current output signals are used. Therefore, SI-702S Ultra-High Pressure Senors is used in applications that require long-distance transmission signals or intelligent control and detection systems.

- Construction of test platform

- Water jet cutting

- High-pressure pasteurization

- High pressure cleaning

- High voltage processor

- Water cutting machinery

- Hydraulic components

- High-voltage systems, etc.

Technical Support

What is a high pressure transducer?

High pressure transducer is a pressure transmitter suitable for high pressure measurement and control.

Sino-Inst high pressure transducer has gone through thousands of fatigue impact tests and several days of low and medium temperature aging cycles before leaving the factory. It has solved the disadvantages of high pressure sensors in terms of stress and zero instability. Provide customers with reliable products for high voltage measurement. The pressure of SI-702 series can reach 600MPa. The precision level is high, and the mature production technology can ensure the long-term stability of the sensor with excellent characteristics. SI-702 series pressure sensors are suitable for oil extraction platforms, water flow equipment, high pressure measurement equipment, hydraulic control systems, test benches and industrial automation control.

More about high pressure transducer wikipedia.

FAQ

What does a pressure transducer do?

A pressure sensor (Pressure Transducer) is a transmitter that can sense pressure signals and convert them into usable output electrical signals according to certain rules.

The pressure sensor usually consists of a pressure sensitive element and a signal processing unit. According to different test pressure types, pressure sensors can be divided into gauge pressure sensors, differential pressure sensors and absolute pressure sensors.

How do you test a pressure transducer?

Today I will mainly introduce three common detection methods for pressure sensors. Hope it helps everyone.

1. Pressure test. The method of detection is to power the sensor. Use your mouth to blow the air hole of the pressure sensor. Use the voltage file of a multimeter to detect the voltage change at the output of the sensor. If the relative sensitivity of the pressure sensor is large. This amount of change will be obvious. If nothing has changed. You need to use a pneumatic source to apply pressure instead.

2. Zero point detection. Use the voltage file of a multimeter. Detect the zero output of the sensor under no pressure. This output is generally mV level voltage. If the technical specifications of the sensor are exceeded, the zero deviation of the sensor is out of range.

3. Detection of bridges. It mainly detects whether the circuit of the sensor is correct. It is generally a Wheatstone full-bridge circuit. Use the ohm file of the multimeter to measure the impedance between the input terminals and the impedance between the output terminals. These two impedances are the input and output impedances of the pressure sensor. If the impedance is infinite, the bridge is disconnected. It means there is a problem with the sensor or the definition of the pin is not correct.

How does a 3 wire pressure transducer work?

The output signal of the two-wire pressure transmitter is generally 4-20MA. The supply voltage is 24VDC. The two wires are a red (representing positive 24V power supply), and a black or blue (representing positive signal output). The wiring method is that the red wire is connected to the positive source and the blue wire is connected to the signal positive, and then the power supply negative and the signal negative are shorted.

The three-wire pressure transmitter is generally a voltage output. Wire one (red power supply is positive), one black (power supply is negative), and one yellow (signal output is positive). The output ground is common to the power supply.

Why shouldn’t you use a pressure transducer with high oxygen environment?

Oxygen plays an important role in the smelting process, chemical industry, national defense industry, and healthcare. However, the process of oxygen production and use is extremely prone to combustion and explosion.

The analysis is based on the mechanism of the “three elements” of combustion and explosion (combustible materials, oxidants, and excitation energy). The high-purity high-pressure oxygen transported in the oxygen pipeline is a very strong oxidant. The higher the purity, the higher the pressure, the stronger the oxidation, the more dangerous.

The potential sources of excitation energy for combustion or explosion are roughly the following: friction, compression heat, impact force, arc, resonance, etc.

In the construction of industrial oxygen pipelines, multiple cleaning processes such as derusting, scrubbing, sand blasting, blowing, degreasing, and acid cleaning should be carried out. Remove the oil and impurities in the pipeline to make it reach the condition of transporting oxygen medium. Check and accept according to relevant standards, and use it after passing the test.

For oxygen pressure measurement, choosing a clean instrument filled with inert oil not only improves the safety level, but also greatly reduces the risk of economic and time loss caused by maintenance or failure replacement.

Sino-Inst pressure sensor for oxygen measurement

Accuracy: ± 0.15% FS

Fill with Fluorolube® oil to ensure no oxidation reaction

Oil-free production process, oxygen-level cleaning process

Φ19mm standard OEM pressure / differential pressure sensor

Constant current / constant voltage power supply

All stainless steel 316L material

Sino-Instrument offers High pressure sensors. A wide variety of High Pressure sensors options are available to you. Such as free samples, paid samples. Sino-Instrument is a globally recognized manufacturer of High Pressure sensors, located in China. Sino-Instrument sells through a mature distribution network that reaches all 30 countries worldwide. Pressure sensors products are most popular in Europe, Southeast Asia, and Mid East. You can ensure product safety by selecting from certified suppliers. With ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.