OEM Pressure Sensor is an economical product. It uses all stainless steel wetted parts, has a compact size and high cost performance.

This pressure transmitter measures gauge pressure and absolute pressure. The measurement system is fully welded and can be used for most liquid and gas media. This series provides a variety of electrical outputs as well as electrical connections and pressure interfaces to meet most application requirements. The compact structure is very suitable for installation in a small space.

Sino-Inst offers a variety of OEM pressure senors for industrial pressure measurement. If you have any questions, please contact our sales engineers.

Industrial OEM Pressure Sensor Features

- Measuring range: 0-0.6,1,2,5,10,20,30,40,50,60 ~ 150MPa;

- Available in gauge, absolute and sealed gage styles;

- Constant current / constant voltage power supply;

- Isolated structure, suitable for a variety of fluid media;

- Standard OEM pressure sensitive element;

- All 316L stainless steel;

- Tantalum diaphragm optional, titanium structure optional;

- Standard male thread pressure connection available;

- Flexible customer customization ;

Specifications

- Measuring range: 0-0.6,1,2,5,10,20,30,40,50,60 ~ 150MPa

- Comprehensive accuracy: 0.1% FS, 0.25% FS, 0.5% FS

- Output signal: 1.0mV / V, 1.5mV / V, 2.0mV / V

- Power supply voltage: 10VDC (3 ~ 15VDC)

- Output impedance: 350/1000/1650 / 2000Ω

- Medium temperature: -20 ~ 85 ℃ ~ 125 ℃

- Ambient temperature: -20 ~ 85 ℃

- Insulation resistance: greater than 2000MΩ / 100VDC

- Response time: <1-5ms

- Sealing grade: IP65

- Long-term stable performance: 0.15% FS / year

- Vibration effect: within the mechanical vibration frequency of 20Hz ~ 1000Hz, the output change is less than 0.1% FS

- Electrical connection: red-positive power, black (yellow)-negative power, blue-positive signal, white-negative signal

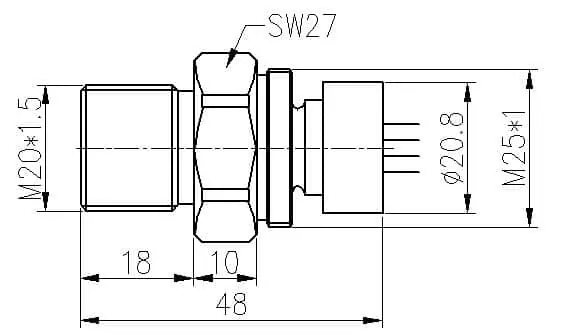

- Mechanical connection: M20 × 1.5, other threads can be customized according to customer requirements

5 Types of Industrial Pressure Sensors

Piezoelectric pressure sensor:

Piezoelectric effect is the main working principle of piezoelectric sensors. Piezoelectric sensors cannot be used for static measurement. Because the charge after external force is applied, it can only be saved when the loop has infinite input impedance. This is not the case, so this determines that piezoelectric sensors can only measure dynamic stress.

Ceramic pressure sensor:

Ceramic pressure sensors are based on the piezoresistive effect. Pressure directly acts on the front surface of the ceramic diaphragm, causing the membrane to deform slightly. Thick film resistors are printed on the back of the ceramic diaphragm and connected into a Wheatstone bridge. Because of the varistor The piezoresistive effect makes the bridge generate a voltage signal that is highly linear and proportional to the pressure and proportional to the excitation voltage. The standard signal is calibrated to 2.0 / 3.0 / 3.3mv / v according to different pressure ranges. Strain sensors are compatible.

Diffused silicon pressure sensor:

The working principle of a diffused silicon pressure sensor is also based on the piezoresistive effect. Using the piezoresistive effect principle, the pressure of the measured medium directly acts on the diaphragm of the sensor (stainless steel or ceramic). The diaphragm produces a micro-displacement proportional to the pressure of the medium. Change the resistance value of the sensor. Use electronic circuits to detect this change, and convert and output a standard measurement signal corresponding to this pressure.

Sapphire pressure sensor:

Utilizing strain-resistance working principle. Using silicon-sapphire as the semiconductor sensitive element has unparalleled metrological characteristics. Therefore, silicon-sapphire semiconductor sensitive components are used. They are not sensitive to temperature changes and have good working characteristics even under high temperature conditions. Sapphire has extremely strong radiation resistance. In addition, silicon-sapphire semiconductor sensitive components, pn drift.

Piezoresistive force sensor:

Resistance strain gage is one of the main components of a piezoresistive strain sensor. The working principle of a metal resistance strain gage is that the resistance of the strain resistance absorbed by the base material changes with the mechanical deformation.

Applications of OEM pressure sensor

Industrial process control: liquid level measurement, gas, liquid pressure measurement;

Pressure testing instruments: pressure calibration instruments, hydraulic systems and switches; refrigeration equipment and air conditioning systems, aviation and marine testing.

More Featured Pressure Measurement Solutions

- How to Calibrate a Pressure Transmitter

- Differential Pressure Transmitter Installation Guide

- Use Differential Pressure Transmitter to Measure Liquid Level

- MEMS Pressure Sensors

- Application Analysis of Intelligent Pressure Transmitter

- Differential Pressure Flow Meters

- Water Pressure Transducers

- Capacitive pressure transducer

- Pressure indicator transmitters

- How Does a Pressure Transmitter Work?

- Pressure Transmitter Calibration

- SMART HART Pressure Transmitter

OEM pressure transmitter manufacturer in China

Sino-Inst sensors are produced in three basic configurations: gauge pressure sensors, absolute pressure sensors and sealed gauge pressure sensors.

A large percentage of OEM pressure sensors produced by Sino-Instrument, are used in our own pressure transducers, and pressure transmitters, so Sino-Inst understands the OEM viewpoint.

Whatever the need, Sino-Inst can provide the solution!

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.