Magnetostrictive Level Transmitters are level sensors for continuous level measurement. It is the best technology for monitoring and controlling liquid level interface.

Magnetostrictive Level Transmitters are used for continuous measurement of liquid level and interface. Magnetostrictive level measurement is currently the best liquid level measurement and control technology.Sino-Inst’s Magnetostrictive Level Transmitters can provide two independent outputs: interface; overall level. It can be applied when the difference in specific gravity drops to 0.02. Magnetostrictive Level Sensors Commonly used for the measurement of the oil-water interface. And others include acid tanks, propane containers, desalter and sewage tanks. Magnetostrictive Level Transmitters are composed of three parts: probe rod, circuit unit and magnetic float. The flexible cable type and the outer buoy type are derived from the basic model. And has a variety of communication modes 4~20mA, 0~5V, 0~10V, HART, RS-485 and so on.

Sino-Inst offers a variety of magnetostrictive level transmitters for industrial level measurement. If you have any questions, please contact our sales engineers.

Featured Magnetostrictive Level Transmitters

Features of Magnetostrictive Level Transmitters

Magnetostrictive Level Transmitters are divided into three types: flexible probe type, hard probe type, and outer float isolation detection. The watch body contains two main parts: the electronic part and the sensing part. The advantages of Magnetostrictive Level Transmitters are:

- Strong reliability:

Because the magnetostrictive liquid level gauge adopts the principle of waveguide, there is no mechanical movable part. Therefore, there is no friction and no wear. The entire converter is enclosed in a stainless steel tube and is not in contact with the measurement medium. The sensor works reliably and has a long life. - High precision:

Because the magnetostrictive liquid level gauge works with waveguide pulses. In the work, the measured displacement is determined by measuring the time of the start pulse and the end pulse. Therefore, the measurement accuracy is high and the resolution is better than 0.01%FS. The accuracy achieved. - Good security:

Magnetostrictive liquid level gauge has high explosion-proof performance. Intrinsically safe explosion-proof and safe to use. Especially suitable for the measurement of chemical raw materials and flammable liquids There is no need to open the tank lid during the measurement. Avoid the unsafeness of manual measurement. - Easy to install and maintain:

The magnetostrictive liquid level gauge is generally installed through the existing pipe opening on the top of the tank. It is especially suitable for the installation of underground storage tanks and storage tanks that have been put into operation. It can not affect normal production during the installation process. - Facilitate system automation:

The secondary instrument of the magnetostrictive liquid level gauge adopts the standard output signal. It is convenient for the computer to process the signal. It is easy to realize the network work and improve the automation degree of the entire measurement system.

Sensing part (ie probe rod):

The probe has a diameter of 5/8” and the end is sealed. The inside of the probe is hollow and equipped with precision magnetostrictive wires. In addition to the magnetostrictive wires, the probe can also hold up to 8 RTD The sensor is used to detect the temperature. The maximum length of the probe can be 23 meters, and the flexible cable structure is used above 6 meters.

Electronic part (ie controller):

The shell is made of aluminum alloy or 304 stainless steel. It is a double-chamber type (that is, the transmission part is separated from the wiring part). One of the chambers is a micro-processing module and a circuit board, and the micro-processing module has operation buttons. The other chamber is a binding post. There is a wire connected between the circuit board and the probe processing board. This wire should not be loosened without authorization from the manufacturer.

magnetostrictive level transmitter working principle

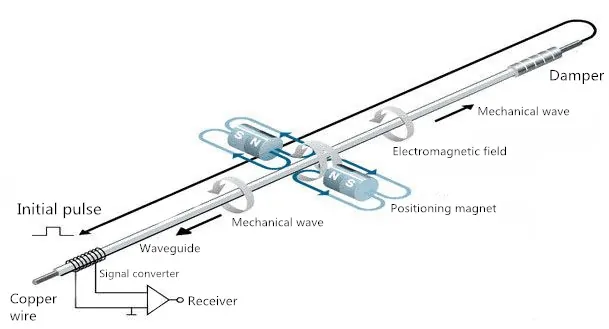

The magnetostrictive liquid level/boundary transmitter is designed using a physical phenomenon – the principle of magnetostriction. The specific working principle is as follows:

A fine magnetostrictive wire is installed in a non-magnetic sensing tube. A piezoelectric sensor is connected to one end of the magnetostrictive wire. The piezoelectric sensor sends 10 current pulse signals to the magnetostrictive wire every second. and time it.

The current pulse travels down the magnetostrictive wire. A circular magnetic field is generated that moves downward.

The annular magnetic field interacts with the magnetic field of the magnetic float. A torsional stress wave is generated on the magnetostrictive line. This torsional stress wave travels from the float position up and down the magnetostrictive line at a known speed. Knowing The piezoelectric magnetic sensor receives this torsional stress wave signal.

The time interval between the initial current pulse wave and the return torsional stress wave can be known through the timing circuit. The position of the float can be determined according to the time interval. Since the float always floats on the liquid surface, the liquid level can be accurately determined s position.

Applicaitons of Magnetostrictive Level Transmitters

| Industries served: | Applications: |

|---|---|

| Oil and Gas | Position Sensing |

| Petrochemical | Sanitary Service |

| Chemical | Valve Positioning |

| Power Generation | Inventory Control |

| Water and wastewater treatment | Corrosive Process |

| Pulp and Paper | Underground Tanks |

| Biotech | Primary Level/Interface |

| Marine | Process Temperature and Level |

Extended Reading: Low Cost Float Level Sensor for Tank Liquid Volume Monitoring

magnetostrictive level transmitter advantages and disadvantages

When the sensor of the magnetostrictive liquid level transmitter works, the circuit part of the sensor will excite a pulse current on the waveguide wire. When the current propagates along the waveguide wire, a pulsed current magnetic field is generated around the waveguide wire.

Magnetostrictive level transmitter advantages:

- The magnetostrictive liquid level gauge is suitable for liquid level measurement of clean liquid level with high precision requirements. The precision reaches 1mm, and the product precision can reach 0.1mm.

- It can be used to measure the interface between two different liquids.

- The biggest advantage of magnetostriction lies in its extremely high resolution, which can be at the micron level. A typical application is to measure the position of a rolling mill load hydraulic cylinder. But the design here is not the same as level measurement. The position measurement of the hydraulic cylinder is not that the hydraulic oil drives the magnetic ring (ie, the floating ball). Instead, the movable part of the cylinder body drives the magnetic ring to move through the mechanical structure, so the position is very clear. Usually, the precision requirements of the rolling mill for the thickness of the sheet are usually several to tens of microns. Therefore, the resolution of the magnetostrictive sensor must reach the micron level.

- The explosion-proof intelligent electronic circuit design can calculate the volume

- The movable part of the magnetostrictive liquid level gauge is a float, and the maintenance is extremely low. It is used in liquid level measurement of various storage tanks and has the characteristics of strong environmental adaptability and convenient installation.

Compared with liquid level gauges such as radar, it has a very high cost performance and many functions in short-range measurement. The display screen has current, temperature and interface display. This is exactly why the magnetostrictive level gauge can become one of the most common products used on metering tanks such as gas stations today.

Disadvantages of magnetostrictive level transmitter:

- The anti-interference ability is slightly poor (generally it is not recommended to be used in places with strong electromagnetic radiation such as power plants).

- It must be a contact measurement, but the real measurement unit is not in contact with the liquid, and only its protection tube is in contact with the liquid.

- The medium is in direct contact, and the floating ball sealing requirements are strict, and the viscous medium cannot be measured.

- Installation is limited. Higher installation and maintenance requirements, so the market is not widely used.

Extended reading: How To Select Hydraulic Flow Meter?

Magnetostrictive level transmitter price

The price of a magnetostrictive level transmitter is determined based on the measurement conditions. Sino-Instrument is a manufacturer of magnetostrictive level gauges. We offer magnetostrictive level gauges at the right price.

Selection considerations:

1. The selection of the level gauge should be consistent with the environment of the media on the site. Including ambient temperature, pressure, vibration, shock, compatibility of structural materials and media, etc.

2. When the temperature of the measured medium is high (100 ~ 200), it is recommended to choose a probe with an outer float type and use a side flange installation. When the temperature is higher (200 ~ 300), it is recommended to choose a probe with a side-bundled type with an outer float, and install it with a side flange.

3. There are measurement dead zones at the upper and lower ends of the measuring rod of the magnetostrictive level gauge, which should be considered when selecting the range.

4. The size of the stainless steel magnetic float commonly used for level gauges is Ф45 × 56 × Ф15, and flange connection of DN50 or above is required. For the liquid level gauge with thread connection, users need to install flange or bracket.

More Level Senors for Tank Level Measurement

Frequently

Asked

Questions

Related tank liquid level measurement solutions

Sino-Instrument offers over 10 Magnetostrictive level transmitters for level measurement. About 50% of these are Magnetostrictive liquid level meters, 40% is the tank level sensor.

A wide variety of Magnetostrictive level meters options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Magnetostrictive level measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.