What is Magnetic Flow Meter?

Magnetic Flow Meter is a flow meter that measures the flow of conductive fluids. Abbreviated as EMF, also called Electromagnetic flowmeters. It is a kind of Volumetric flow meter. A magnetic flow meter measures the velocity of conductive liquids moving through a pipe or conduit. In the wastewater treatment industry, Magnetic Flow Meter is the best flow meter choice.

Sino-Inst offers a variety of Magnetic Flow Meters for flow measurement. If you have any questions, please contact our sales engineers.

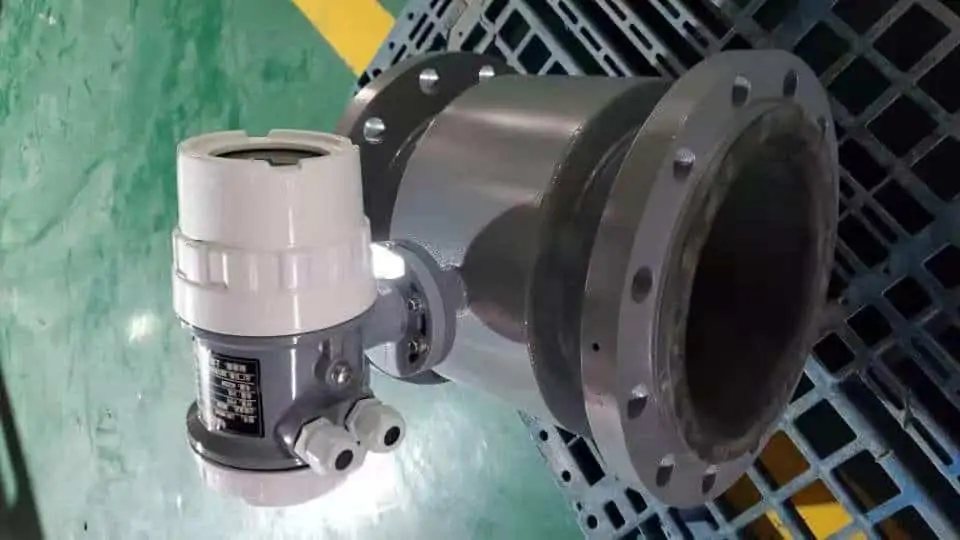

Featured Magnetic Flow Meters

Magnetic Flow Meters Features

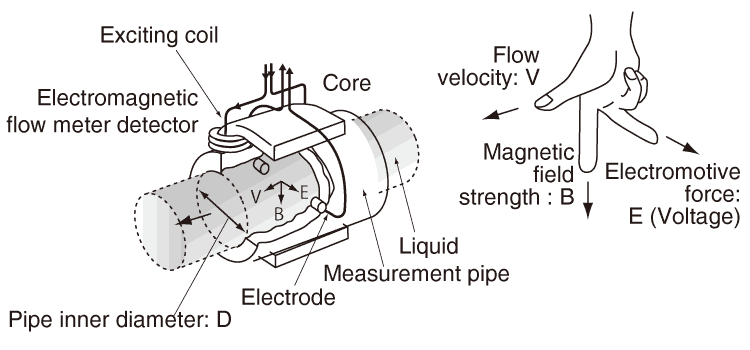

Magnetic flow meter working principle

Magnetic flow meters use the principle of Faraday’s Law of Electromagnetic Induction to measure the flow rate of liquid in a pipe. In the magnetic flowmeter pipe parts, a magnetic field is generated, and channeled into the liquid flowing through the pipe.

Faraday’s Law states that the voltage generated is proportional to the movement of the flowing liquid. A conductor moving through a magnetic field produces an electric signal within the conductor. And the singal is proportional to the velocity of the water moving through the field.

As fluid flows through the magnetic field, conductive particles in the fluid create changes. This variation is used to measure and calculate the velocity of water flow through the pipe. When the fluid moves faster, more voltage is generated. The electronic transmitter processes the voltage signal to determine liquid flow.

Magnetic flow meter principle – Faraday’s Formula

Faraday’s Formula

E is proportional to V x B x D where:

E = The voltage generated in a conductor

V = The velocity of the conductor

B = The magnetic field strength

D = The length of the conductor

To apply this principle to flow measurement with a magnetic flow meter. First is to state that the fluid being measured must be electrically conductive for the Faraday principle to apply.

As applied to the design of magnetic flow meters, Faraday’s Law indicates that:the signal voltage (E) is dependent on V, B, D.V is the average liquid velocity ;

B is the magnetic field strength ;

D is the length of the conductor ( which in this instance is the distance between the electrodes).

To learn more about Magnetic Flow Meters, this video by Emerson gives a good explanation.

Video source: https://www.youtube.com/watch?reload=9&v=lRSjYjg9WRo

Advantages of using Electromagnetic Flow Meters.

- High precision and stability

- Self-check

- Two-way measurement

- No pressure loss

- No moving parts

- May be for sanitary purposes

- Large size available

- Dirty liquid and mixed fructose are ok

Disadvantages of using Magnetic Flow Meters

- Can not be used to measure gas, steam and liquids containing a lot of gas;

- Cannot be used to measure liquid media with very low conductivity.

- Cannot be used to measure high temperature media. At present, it is restricted by the lining material and electrical insulation material of the measuring tube of the electromagnetic flowmeter for general industry;

- The electromagnetic flowmeter is easily affected by external electromagnetic interference.

Magnetic flow meter diagram

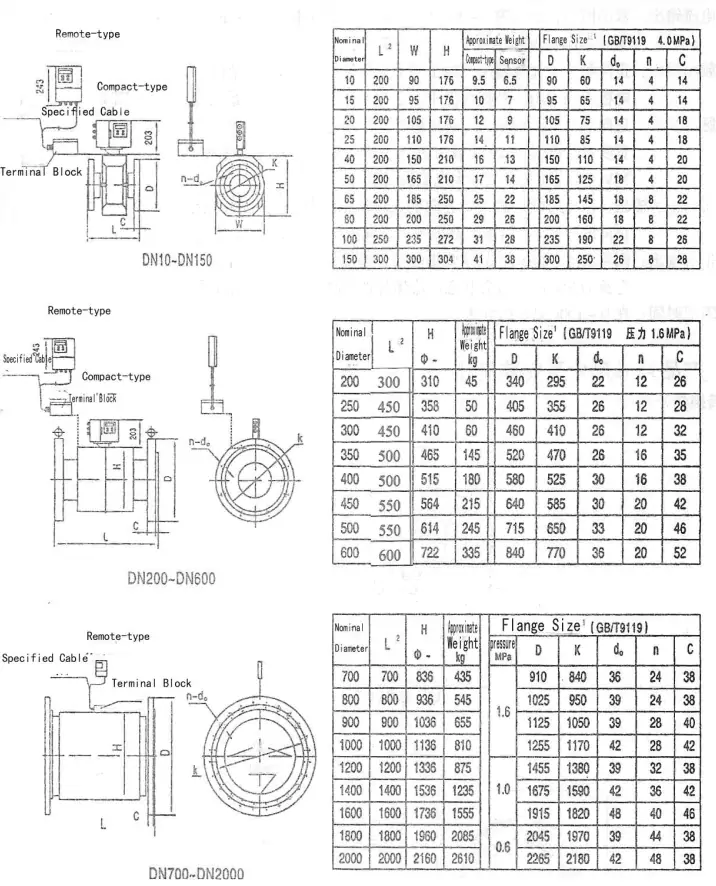

Dimensions of Converter, shown as Fig 3.

Dimensions of Sensor, shown as Fig 4.

Remark:

1. Nominal Pressure 4.0 MPa for DN10-150; Nominal Pressure 1.6 MPa for DN10-1000; Nominal Pressure 1.0 MPa for DN10-1600; Nominal Pressure 0.6 MPa for DN10-2000. Other special pressure level can be designed on demand.

2. The length L increases 6 mm if ground flange is equipped; The length L increases 6 mm if inlet protection flange is equipped; The length L increases 6 mm if liner protection flange is equipped.

Magnetic flow meter accuracy

The accuracy of the electromagnetic flowmeter supplied by Sino-Inst is 0.5%, 0.2% optional.

How to understand the accuracy of electromagnetic flowmeter?

The absolute value of the difference between the measured value and the true value is compared with the true value, and the number in front of the obtained percentage is the accuracy. If the number is less than 0.5 and greater than 0.2, the general accuracy is called 0.5 level.

For example: the measured value is 100.5 or 99.5, the true value is 100, and the obtained percentage is 0.5%, which means that the accuracy is 0.5. But if the number in front of the percentage is less than or equal to 0.2, it is called 0.2 level accuracy.

Such as:

- Rosemount magnetic flow meter’s Accuracy: Up to 0.15% of volumetric flow rate accuracy over 13:1 flow turndowns, 0.25% over 40:1 flow turndown

- Yokogawa magnetic flow meter Accuracy: ±0.35% of flow rate

Read more about: Why Is Turndown Ratio Important?

Magnetic Flowmeter Applications

Electromagnetic flowmeters have been used for more than 50 years and have been widely used worldwide. The fields involve water/sewage, chemical, pharmaceutical, paper, food and other industries.

Large-caliber meters are mostly used in water supply and drainage projects.

Small and medium calibers are often used in places where solid and liquid are both equal and difficult to detect fluids or high requirements.

Small calibers and tiny calibers are often used in places with hygiene requirements such as the pharmaceutical industry, food industry, and biological engineering.

- Water / Wastewater Industry

- Food and Beverage

- Metals

- Brewing, Distilling, and Wine makening

- HVAC

- Chemical

- Pulp and Paper

- Pharmaceutical

- Mining, Mineral Processing

Extended Reading: Metal Tube Flow Meter Applications

Magnetic flow meter troubleshooting

Every measurement process is unique. Any instrument may have problems during use.

In the process of using the electromagnetic flowmeter, if there is a measurement problem. Please check whether the following problems occur first, and try the corresponding solutions.

If the problem is not listed below, please contact Sino-Inst staff in time. We will provide you with suggestions for problem solving.

| Phenomenon | Solution |

| No display | a) Check the connection of power supply; b) Check fuse; c) Check the voltage of power supply; d) Check if the LCD contrast can be adjusted. Adjust it if possible; e) Return to base, if a) to d) are OK. |

| Coil Alarm | a) Check if terminal EXT+ and EXT- are open; b) Check if coil resistance is less than 150Q; c) Replace converter if a) and b) are OK. |

| Empty Pipe Alarm and Electrodes Alarm | a) Check if the sensor pipe is filled with fluid; b) Check the connection of signal wiring; c) Connect the terminal SIG1, SIG2 and SIG GND. If the alarm display disappears, it is confirmed the converter is normal. The alarm may be caused by the bubble in the fluid; d) For electrodes alarm, measure the resistance between two electrodes with a multimeter. The read should be between 3 to 50k. Otherwise, the electrodes are contaminated or covered. |

| High Alarm | Increase the flow range. |

| Low Alarm | Reduce the flow range. |

| Inaccurate Measurement | a ) Check if the sensor pipe is filled with the fluid to be measured . b) Check the wiring; c ) Check if the sensor factor and flow zero are the same as those on the calibration sheet . |

Extended Reading: Guide: Magnetic Flowmeter Installation

Magnetic flow meter price

Magnetic Flow Meter has different calibers, different materials, different media, different linings, different meter heads, and different functions, so the price is different!

The Magnetic Flow Meter price list is attached below for reference only!

The final quotation is subject to the parameters!

| Diameter/DN | Lining rubber (USD) | Lined with PTFE (USD) | Electrode | Power | Material |

| DN15 | 485 | 647 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN20 | 493 | 647 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN25 | 500 | 647 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN32 | 537 | 654 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN40 | 566 | 654 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN50 | 588 | 662 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN65 | 618 | 676 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN80 | 676 | 691 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN100 | 706 | 750 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN150 | 728 | 794 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN200 | 757 | 838 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN250 | 809 | 985 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN300 | 926 | 1118 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN350 | 985 | 1368 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN400 | 1081 | 1441 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN500 | 1184 | 1765 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN600 | 1368 | 1904 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN700 | 1640 | 3574 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN800 | 2556 | 3868 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN900 | 3088 | 4574 | 316L (Standard configuration) | 24V/220V | Carbon steel |

| DN1000 | 4044 | 5926 | 316L (Standard configuration) | 24V/220V | Carbon steel |

Factors affecting the price of Magnetic Flow Meters

- The larger the diameter of the flowmeter, the higher the price. For example, DN250 electromagnetic flowmeter is more expensive than DN25 electromagnetic flowmeter. On the contrary, the smaller the diameter, the lower the price.

- The flowmeter is divided into: integrated type and split type. Split type electromagnetic flowmeter is more expensive than integrated type electromagnetic flowmeter. The high reason is that the expensive money for the split type is shielded wire money.

- The flowmeter is divided into: ordinary type, anti-corrosion type, anti-corrosion type. The price of electromagnetic flowmeter is higher than that of ordinary electromagnetic flowmeter. The reason for the higher price is that the lining is distinguished. The anti-corrosion type is tetrafluoroethylene lining, mainly for measuring acid Alkaline medium. The common type is rubber lining, mainly for measuring sewage and ordinary water medium.

You may like:

Sino-Inst offer over 50 Magnetic Flow Meters, with Best Price.

A wide variety of Magnetic Flow Meters options are available to you, such as free samples, paid samples.

About 13% of these are magnetic flow meter, 14% are Insertion Magnetic Flow Meter, 25% are Venturi flow meter, 13% are ultrasonic flow meter, and others are Liquid Turbine Flow Meters.

Sino-Inst is Magnetic Flow Meters suppliers, located in China. Magnetic Flow Meters products are most popular in North America, Mid East, and Eastern Europe. The United States, and India, which export 99%, 1%, and 1% of Magnetic Flow Meters respectively.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.