Ultrasonic Clamp on Flow Meter is composed of an integrated host and external clamp on sensors. Clamp on Flow Sensors are available at room temperature and high temperature.

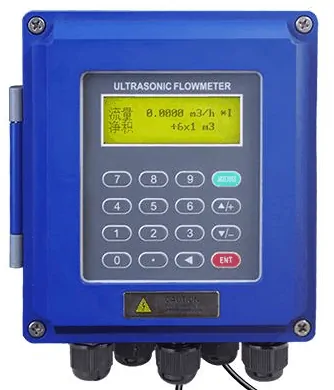

Clamp on flow meter (Model: 2000) is composed of an integrated host and ultrasonic clamp on sensor. Clamp on flow meter is widely used in online flow measurement of various liquids. Just stick the external clamp sensor on the pipe surface. Compared with the traditional flowmeter, it does not need to cut off the pipe and flow. The installation is convenient and quick, and the non-destructive installation is truly realized.

Clamp on Flow Meter Reference price: USD 470.00/pc

Sino-Inst offers a variety of Ultrasonic flow meters for flow measurement. If you have any questions, please contact our sales engineers.

Features Of Ultrasonic Clamp-on Flow Meter

- High Accuracy measuring

- Linearity: better than 0.5%, Repeatability: better than 0.2%, Accuracy: better than ±1%

- Wide Measuring Range

- Several types transducer for selection, measuring pipe size from DN15mm to DN6000mm

- English menu

- Different version UFM can support English display, easy to operate

- High Reliability

- Adopt low voltage, multi-pulse technology to improve accuracy, useful life and reliability

- Strong Anti-interference

- Dual-balance signal differential receiver/driver circuit to avoid interference of converter, TV tower, high voltage line etc.

- Powerful Recording Function

- Automatically record the following data:

- 1. The totalizer data of the last 512 days/128 months/5 years

- 2. The time and corresponding flow meter of the last 64 times of power on and off events

- 3. The working status of the last 32 days

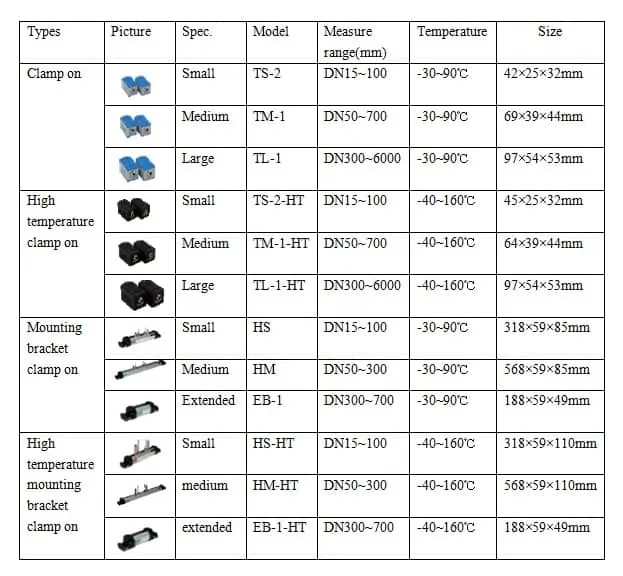

Optional transducers for Ultrasonic Clamp on Flow Meter

Optional Host

According to different installation condition, there are many models separated ultrasonic flowmeter for selection:

Specifications of Ultrasonic Clamp on Flow Meter

| Item | Performance and Parameter | |

| Convertor | Principle | transit-time ultrasonic flowmeter |

| Accuracy |

Flow: over 1%-2%(battery-powered supply over ±2% ),Heat: over ±2%,Repeatability: over 0.2% |

|

| Display |

2×20 character LCD with backlight, support the language of Chinese, English and Italy Convertor dimension:170*180*56cm |

|

| Operation | Support 16 key light touch keyboard and the Simulation keyboard software | |

| Signal Output |

1 way 4~ 20mA output, electric resistance 0~ 1K,accuracy0. 1% |

|

|

1 way OCT pulse output ( Pulse width 6 ~ 1 0 0 0 ms,default is 2 0 0 ms) |

||

| 1 way Relay output | ||

| Signal Input |

3 way 4~ 20mA input, accuracy 0. 1%,acquisition signal such as temperature, press and liquid level |

|

|

Connect the temperature transducer Pt100, can finish the heat/energy measurement |

||

| Data interface |

Insulate RS485 serial interface, upgrade the flow meter software by computer, support the MODBUS, METER-BUS etc. |

|

| Other Function | Automatically remember the previous flow/energy data of 512 days, 128 months and 10 years | |

| Automatically remember the previous flow/energy data of 512 days working condition and check it | ||

| Automatically remember the previous 32 times power on/off time and flow rate | ||

| Special Cable |

Twisted-pair cable, generally, the length under 50 meters; Select the RS485 communication. The transmission distance can over 1000m. |

|

| Pipe Installation Condition | Pipe Material |

Steel, Stainless steel, Cast iron, Copper, Cement pipe, PVC, Aluminum, Glass steel product, liner is allowed. |

| Pipe Diameter | 15mm—6000mm | |

| Straight length pipe |

Transducer installation should be satisfied: upstream10D, downstream 5D, 30D from the pump. |

|

| Measuring Medium | Type of Liquid |

Water (hot water, chilled water, city water, sea water, waste water, etc.); Sewage with small particle content; Oil (crude oil, lubricating oil, diesel oil, fuel oil, etc.); Chemicals (alcohol, acids, etc.); Plant effluent; Beverage, liquid food; Ultra-pure liquids; Solvents and other liquids More about: Sewage Flow Meter Selection |

| Temperature |

Standard Transducer: -30–90℃; High-temperature transducer: -40–160℃ |

|

| Turbidity | No more than 10000ppm and less bubble | |

| Flow rate | 0–±12 m/s | |

| Working Environment | Temperature | Main Unit: -20–60℃ |

| Flow transducer: -40–160℃; | ||

| Temperature transducer: according to the customer’s demands. | ||

| Humidity |

Main Unit: 85% RH; Flow Transducer: Ip67 |

|

| Power Supply | DC 24V or AC 85-264V | |

| Power Consumption | 1.5W | |

Extended reading: Portable ultrasonic flow meter for water

Ultrasonic clamp on flow meter Pros and Cons

Advantages of Ultrasonic clamp on flow meter

- The clamp on ultrasonic flowmeter is convenient to carry, easy to operate, intuitive to read data, and can memorize and save the read data;

- The measurement liquid is relatively wide, including water, sea water, slurry or oil, acid and alkali and other homogeneous liquids;

- Non-contact measurement method, light weight, small size;

- The installation of the clamp-on ultrasonic flowmeter probe is simple, and probes of different sizes can detect pipes of different pipe diameters. Under the condition of ensuring accuracy, the clamp-on ultrasonic flowmeter can measure pipes with a minimum of DN15 and a maximum of DN3000. Pipeline

- The external clamp ultrasonic flowmeter does not need to destroy the pipeline during the flow measurement process, and the probe can directly touch the straight pipe section without pressure loss, and the flow measurement can be performed on the installed pipe;

- Suitable for measuring pipes of different materials. Common metal pipes (stainless steel, carbon steel, cast iron, etc.), plastic pipes, etc., and some pipes with better sound-transmitting materials.

Disadvantages of Ultrasonic clamp on flow meter

Because the temperature of the measured liquid is limited by the temperature resistance of the coupling material between the ultrasonic probe and the pipe, and the original data of the sound transmission velocity of the measured liquid at high temperature is incomplete. At present, the general ultrasonic flowmeter can only be used to measure the fluid below 200 ℃.

The measurement circuit of ultrasonic flowmeter is more complicated than that of general flowmeter. This is because the flow velocity of liquid in general industrial measurement is often a few meters per second, and the propagation speed of sound waves in the liquid is about 1500 m/s.

Therefore, the change of the measured fluid velocity (flow) has the greatest impact on the change of sound velocity, which is also on the order of 10-3. If the accuracy of measuring the flow velocity is required to be 1%, the accuracy of the measurement of the speed of sound needs to be 10-5~10-6 orders of magnitude. Therefore, a complete measurement circuit can be achieved.

This is the reason why ultrasonic flowmeters can only be applied in practice only under the premise of the rapid development of integrated circuit technology.

The measurement accuracy is not high enough. At present, the accuracy level of our ultrasonic flowmeters is generally level 1 or lower. Ultrasonic flow meters are greatly affected by external conditions. For example, high electric and magnetic fields near the measuring pipeline will affect the measurement of the ultrasonic flowmeter.

Read more about: Non-invasive Ultrasonic Tank Level Sensor Working Principle

Portable clamp on flow meter

The portable ultrasonic flowmeter ( Model: 3000H) uses a non-invasive sensor to measure liquid flow. The installation process is extremely simple. There is no need to destroy the pipeline during the measurement process and no need to stop production. The sensor is not in contact with the measured medium. Battery powered, small size, light weight and easy to carry. Realize the real sense of mobile flow measurement, online detection, is a real sense of portable ultrasonic flowmeter.

Handheld Ultrasonic Flow Meter

Handheld Ultrasonic Flow Meter ( Model:2000H) has been successfully applied to measurement work in various industries. The measuring range is 20-6000mm (0.5-20 inches). A non-contact measurement method is adopted. Flexible operation and easy to carry. Conductive or non-conductive, corrosive or non-corrosive liquids can be measured. Various fluids: water, pure water, sewage, sea water, chemical fluids, river water, fuel Oil etc. can be measured.

Check more 1 Inch Flow Meters.

Clamp on Ultrasonic Flow Meter

Clamp on Ultrasonic Flow Meter ( Model: 3000S) is composed of a host and an external clamp sensor. The flow measurement of various liquids can be completed by simply sticking the external clamp sensor on the surface of the pipeline. Compared with the traditional flowmeter, it does not need to cut off the pipe and flow, the installation is convenient and quick, and it truly realizes the lossless installation. Compared with the common TDC algorithm of other manufacturers, TGA measurement technology is an algorithm for measuring process time with higher speed and higher accuracy.

Clamp on liquid flow meter

The external clamp ultrasonic flowmeter can measure the flow rate of a single uniform liquid that can conduct ultrasonic waves, such as water, sea water, sewage, acid and alkali, alcohol, beer, various oils, etc.

Read more about Digital Beer Flow Meters for Sale|Brewery-Wine-Craft Beer Brewing Process management system

Clamp on water flow meter

Clamp on water flow meter refers to the use of external clamp-on ultrasonic flow meters to measure water flow. Especially when other flow meters are not applicable.

For example, the flow measurement of ultrapure water equipment only uses an external clamp-type ultrasonic flowmeter.

why?

Ultra-pure water is non-conductive and has extremely high hygiene requirements, so the clamp-on ultrasonic flowmeter is the first choice. The general contact measurement and conductive medium measurement methods will be excluded. Let’s analyze it in detail below.

First, let’s take a look at the physical characteristics of pure water and ultrapure water. The filter cartridge of the ultra-clean filter device is made of pure polypropylene, and activated carbon is used to remove inorganic and organic trace pollution of ion exchange resin (nuclear grade) and adsorber resin. Dedicated ion exchange resin (nuclear grade) removes inorganic ions. After the adsorber resin removes dissolved organic matter. The pore size of the disinfection filter is 0.2um. The conductivity of pure water and ultrapure water obtained through such purification equipment: 0.055uS/cm. Bacteria content: 1CFU/ml, generally used in fields with high requirements such as biopharmaceuticals.

Secondly, we look at the application conditions of various flow meters.

In addition to measuring the volume flow of general conductive liquids, the electromagnetic flowmeter can also be used to measure the volume flow of strong corrosive liquids such as strong acids and alkalis and uniform liquid-solid two-phase suspension liquids such as mud, mineral pulp, and paper pulp. Since the conductivity of pure water is only 0.055, it cannot be measured.

Look at the turbine flowmeter again. Turbine flowmeter is a contact measurement, and pure water and ultra-pure water have particularly high requirements for materials, so the main material must be 316L when manufacturing, and the use of sanitary clamp joints will increase the production cost immediately.

Clamp on water flow meter is a non-contact meter. It can not only measure the flow of medium with large pipe diameter, but also can be used to measure the medium that is not easy to touch and observe. Its measurement accuracy is very high, and it is almost free from the interference of various parameters of the measured medium. In particular, it can solve the flow measurement problems of strong corrosive, non-conductive, radioactive and flammable and explosive media that other instruments cannot.

In summary, the ultrasonic flowmeter is the best choice for the flow measurement of the purified water equipment in the ultrapure water system.

FAQ

Sino-Inst, Manufacuturer for Ultrasonic Clamp on Flow Meters. It can measure a single sound-conducting liquid medium of DN 25—1200mm. It can measure even liquids such as water, sea water, oil, and slurry.

Sino-Inst’s Ultrasonic Clamp on Flow Meter, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.