B-D Ultrasonic Gas Flow Meter is a pipe section flowmeter. Use mono mode. The sound channel design of the ultrasonic transducer takes into account the requirements of various working conditions. Match the rectifier of corresponding caliber. It can be used for high-precision measurement of pipe sections smaller than DN200.

Sino-Inst offers a variety of Ultrasonic gas flow meters for flow measurement. If you have any questions, please contact our sales engineers.

Features of B-D Ultrasonic Gas Flow Meter

- Overall explosion-proof design;

- No moving parts, no pressure loss, reducing use and maintenance costs;

- The starting flow rate is small. Suitable for measuring low-speed flow;

- Large turndown ratio, turndown ratio 1:125, measuring flow rate from 0.2-25m/s;

- The metering is not affected by the composition. Suitable for measuring multi-component gases or gases with changes in composition;

- The influence of dust and moisture is small. Dirty gases such as coal gas and flue gas can be measured;

- Proprietary algorithm, which can adapt to the measurement occasions with rapid changes in components, rapid changes in temperature, pressure, and humidity;

- Can measure pulsating flow and bidirectional flow;

- Unique operating software design combines waveform debugging and parameter setting. Convenient on-site operation and maintenance;

- Unique maintenance alarm can realize early warning of maintenance time. Provide product stability.

- The all-metal ultrasonic transducer has strong anti-interference ability, dirt resistance and long service life.

B-D Ultrasonic Gas Flow Meter Applications

- It is suitable for the measurement of alkanes such as natural gas, coal bed methane, mine gas, liquefied petroleum gas, methane, ethane, propane, butane, etc.;

- It is suitable for the measurement of gas such as biogas, biological fermentation gas (water-containing impurities), and biomass fuel gas;

- Suitable for the measurement of air, oxygen, nitrogen, argon, helium, nitrogen, and other non-corrosive gases;

- It is suitable for the measurement of flare gas, tail gas, landfill gas, and water treatment aeration;

- It is suitable for the measurement of helium, ammonia, acetylene, and other gases;

💡Industrial Propane Tank Level Indicators for Industrial Tank Level Measurement

B-D Ultrasonic Gas Flow Meter Technical specifications

|

Technical specifications |

|

|

Parameter category |

Specifications |

|

structure type |

Direct type |

|

Applicable caliber |

DN50-DN200 (other calibers can be customized) |

|

Number of channels |

Mono |

|

Flow rate range |

0-25m/s |

|

level of accuracy |

1.5%, 1.0% |

|

Resolution |

0.001m/s |

|

Flow cutoff point |

Qt=0.1 Qmax |

|

Repeatability |

Class 1.0: Qt-Qmax 0.2%; Qmin-Qt0.4% |

|

Work pressure |

Class 1.5: Qt- Qmax 0.3%; Qmin-Qt 0.6% |

|

Measuring direction |

0-1.6MPa (Higher pressure is optional. The default gauge pressure sensor, if you need an absolute pressure sensor, you need to customize) |

|

Measuring medium |

Single way measurement (two-way need to be customized) |

|

Measurement requirements |

|

|

Medium temperature |

-20℃~60℃ (Limit temperature -40℃~85℃) |

|

Ambient temperature |

-25℃~ +55℃ |

|

Signal, communication and other functions |

|

|

output signal |

4-20mA, frequency (pulse) |

|

Communication Interface |

RS-485 |

|

Operating Voltage |

24VDC |

|

Power consumption |

≤3W |

|

data storage |

18 months |

|

Front and rear straight pipe |

10D before, 5D after |

|

Use operation |

Support waveform real-time display and debugging. Set operating parameters through the instrument menu |

|

Alarm function |

When the pressure, temperature, ultrasonic signal, instrument hardware, etc. are abnormal, an alarm is generated, and the alarm information can be obtained through the upper computer software to facilitate maintenance. |

|

Explosion protection |

|

|

Explosion-proof grade |

Ex d mb IIC T5 Gb, |

|

Protection level |

IP65 |

B-D Ultrasonic Gas Flow Meter Flow Range

|

Nominal diameter |

Turndown ratio |

Q max |

Q min |

|

|

Metric system(mm) |

British system (inch) |

(m³/h) |

(m³/h) |

|

|

50 |

2” |

1:80 |

160 |

2 |

|

80 |

3” |

1:80 |

400 |

5 |

|

100 |

4” |

1:80 |

640 |

8 |

|

150 |

6” |

1:80 |

1300 |

18 |

|

200 |

8” |

1:80 |

2200 |

30 |

|

Nominal diameter |

Turndown ratio |

Q max |

Q min |

|

|

Metric system(mm) |

British system (inch) |

(m³/h) |

(m³/h) |

|

|

50 |

2” |

1:150 |

212 |

1.4 |

|

80 |

3” |

1:125 |

450 |

3.6 |

|

100 |

4” |

1:125 |

640 |

5.0 |

|

150 |

6” |

1:125 |

1600 |

13 |

|

200 |

8” |

1:100 |

2260 |

23 |

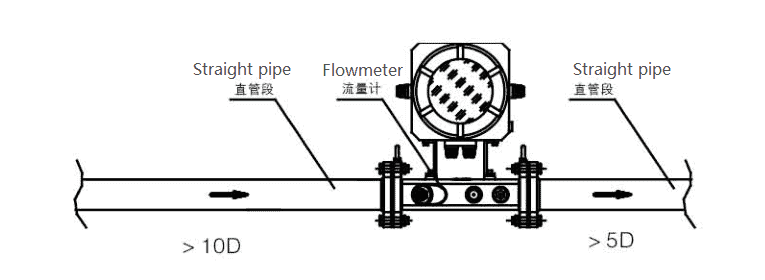

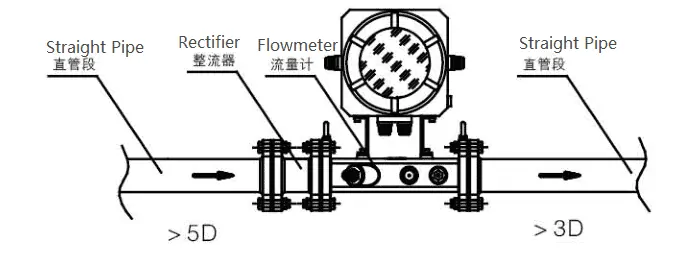

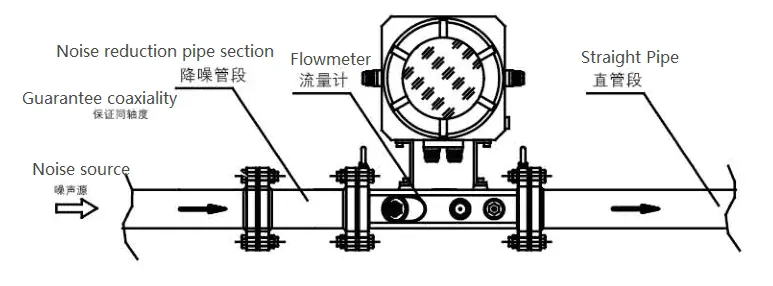

B-D Ultrasonic Gas Flow Meter Straight pipe requirements

a) When there is no rectifier. It is recommended that the length of the front straight pipe is greater than 10D. The length of the rear straight pipe is greater than 5D.

b) With a rectifier. It is recommended that the length of the front straight pipe section is greater than 5D. The length of the rear straight pipe section is greater than 3D.

c) When there are noise sources such as pressure regulating valves on site. A noise reduction pipe section should be installed between the flowmeter and the noise source.

Precession Vortex Gas Flowmeter, like vortex flowmeter, is a velocity flowmeter. The cost performance of the intelligent precession vortex flowmeter is higher than vortex flowmeter. The intelligent precession vortex flowmeter can only measure gas. Precession Vortex Gas Flowmeter can be made into an integrated temperature and pressure compensation. And can measure various gases. Such as compressed air, oxygen, biogas, natural gas, coal gas, etc.

Sino-Inst’s Ultrasonic Gas Flow Meter offer reliable and accurate volume flow measurement in a large range of sizes and pressure rating while being fully compliant with international standards.

Sino-Inst is the risk-free choice for your gas flow measurement applications.

Sino-Inst’s Ultrasonic Gas Flow Meter, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, US, and other countries.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.