Interface level measurement is very important for oil and gas, chemical tanks. At the same time, Interface level measurement is also a measurement and control challenge.

In today’s increasingly modernized oilfield production, automated crude oil processing has become a guarantee for the quality of refined oil. The performance of the oil-water interface fundamentally affects several key issues in crude oil processing: the water content of crude oil, energy consumption, sewage discharge indicators, etc.

Here we mainly compare the working principle, usage and common failures of several oil-water interface instruments commonly used in North China Oilfield. Hope to help you find a suitable solution when measuring oil-water interface.

Interface level measurement technologies

According to the different measurement principles of the interface instrument, the interface instrument can be roughly divided into: magnetic radio frequency admittance type, short wave absorption type, capacitive type, servo type and so on.

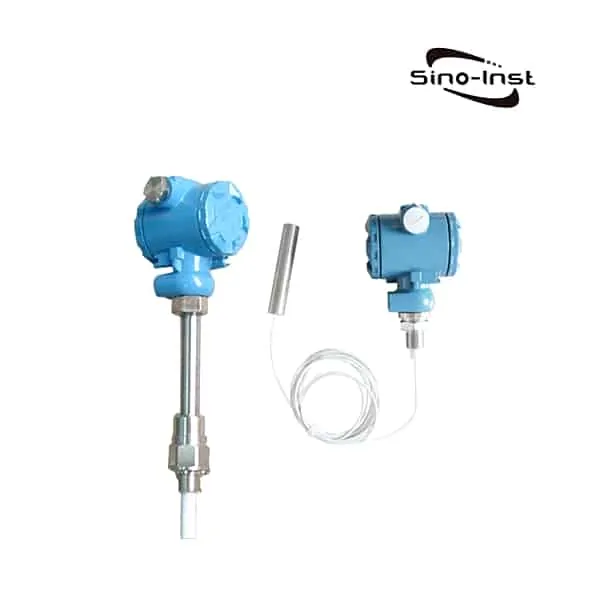

Among them, the magnetic interface instrument is divided into: reed tube type magnetron interface instrument, magnetostrictive interface instrument and other forms.

Interface level measurement using Magnetostrictive interface instrument

During the measurement, the current pulse excites a stress pulse on the waveguide in the tube where the magnetic float is located. Propagate along the waveguide to the measuring part in the top electronic box at the speed of sound. Is converted into electrical pulses.

The position of the liquid level can be determined based on the propagation time of the stress pulse.

If there is a second float, choose the relative density appropriately. Make it float on the oil-water interface. Then the position of the oil-water interface can be measured at the same time.

Interface level measurement using Reed switch level sensor

The reed tube type magnetic control interface instrument is also called the magnetic float ball level gauge.

This type of interface instrument was used earlier in the oil field, and now there are more problems.

The measurement principle is extremely simple. Attach a circuit board consisting of a reed switch and resistors. The length is determined by the height of the measured medium.

Put it into a stainless steel tube, as the magnetic float sleeved outside the steel tube moves with the liquid surface, the magnetic force will attract the corresponding dry reed tube. The resistance value of the output terminal of the circuit board also changes accordingly.

According to the density of the measured crude oil. Appropriately match magnetic floats with different relative densities. The liquid level and interface can be measured.

Know more about: Continuous Float Level Sensor & Switches

Interface level measurement using Shortwave

The meter is based on the theory of medium absorption of short waves. Electric energy is radiated into the oil-water medium in the form of an emulsion in the form of electromagnetic waves. The content of the two media is detected based on the difference in the electric energy absorbed by the oil and water.

The dielectric constant of oil is about 2.3, while that of water is about 80. There is a great difference between the two.

The oil-water interface is detected by measuring the oil-water content.

Extended reading: Radar Oil Tank Level Sensor

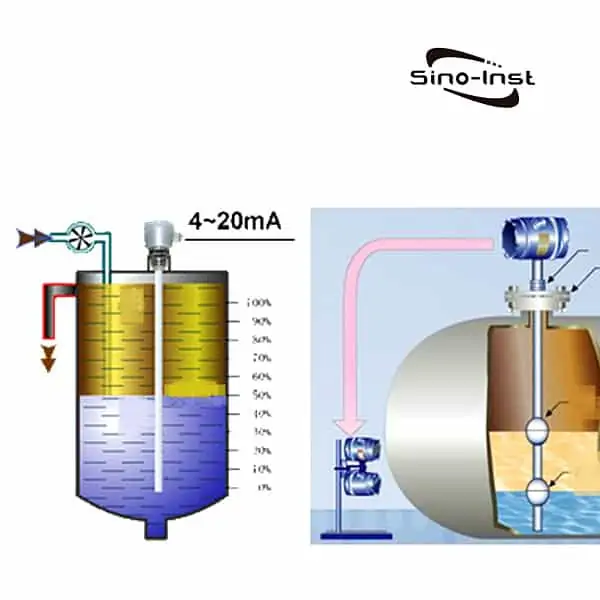

Interface level measurement using Capacitive

Capacitive interface meter uses the difference in electrical conductivity between oil and water media to make the capacitance and the height of the water have a linear relationship. To achieve the purpose of monitoring the oil-water interface.

Nowadays, radio frequency admittance type is used to replace the traditional capacitive interface instrument.

Capacitive Level Sensors can be used for point level detection and continuous level measurement, particularly in liquids. The measuring principle is based on the change of the capacitance in a capacitor. The electrically conductive tank wall and a probe inside of the tank form a capacitor, The capacity changes of which are used to determine the level. This animation shows the measuring principle in conductive liquids and non-conductive liquids. The Capacitive Level Sensor can convert the changes of various levels and the height of the liquid level into standard current signals. Level Sensors can also support wireless transmission, RS485 digital communication transmission, etc.

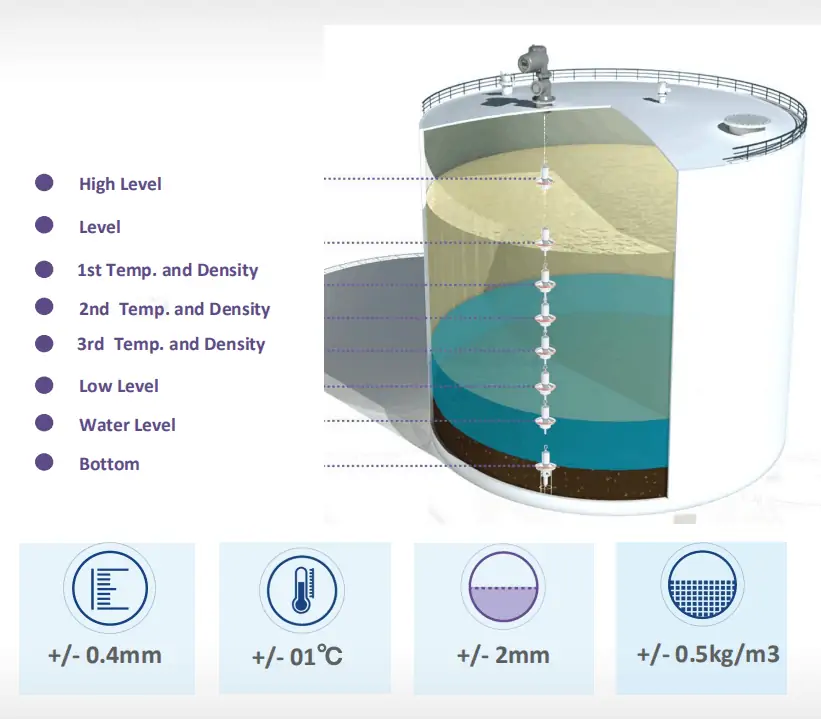

Interface level measurement using Servo Level Meter

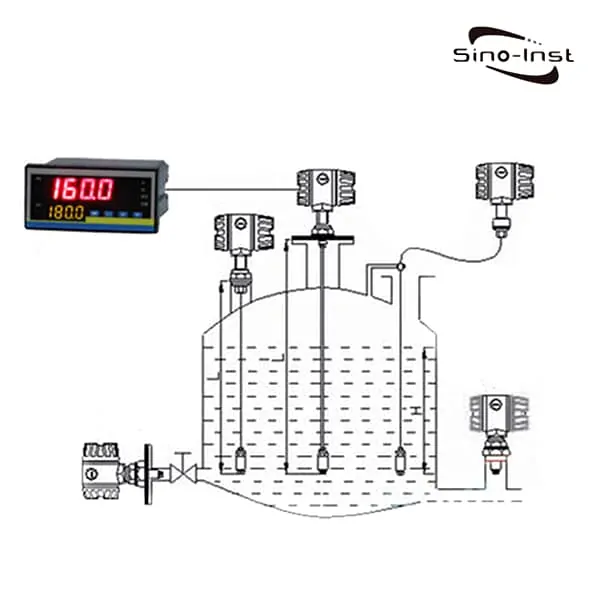

Servo Level Meter is a high-precision measuring instrument that measures the level of liquid level with microelectronic technology and servo motor drive technology.

Servo Level Meter can carry out routine and accurate measurement and signal transmission of liquid level, interface level and density of the measured medium. It also has functions such as temperature transmission. It can meet the requirements of storage tank inventory management, loss control cost saving and safe operation.

Servo Level Meter is explosion-proof design and has strong expandability. It can be widely used in a variety of flammable and explosive places. It is an ideal choice for liquid level measurement in storage tanks in the fields of petroleum and petrochemical, electric power, medicine, and food.

Single Servo Level Meter: It can realize real-time oil tank level, boundary level measurement display and remote transmission display.

Servo Level Meter is equipped with a multi-point thermometer: it can realize the temperature measurement of the oil tank’s liquid level, boundary level, and different point heights on site.

Servo Level Meter is equipped with a multi-point thermometer and a tank side display: it can measure and display the liquid level, boundary level and temperature of the oil tank at different heights on site.

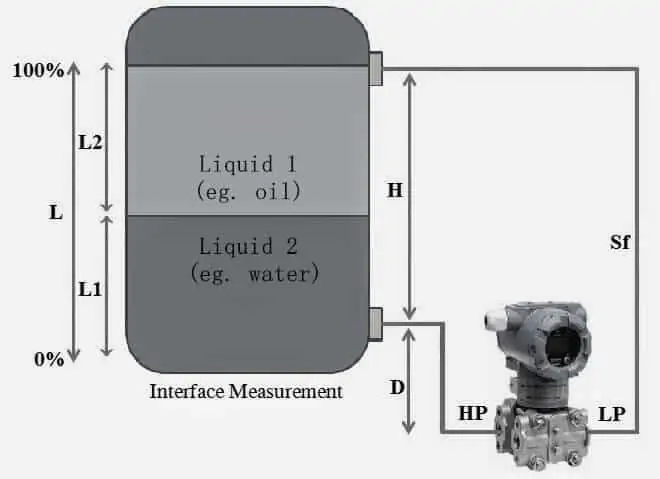

Interface level measurement using DP transmitter

Differential pressure (DP) transmitters are used to measure the interface of two fluids with different specific gravities. This measurement can be made with or without a distal seal. It is important that the height must be large enough to create a reasonable DP between the two specific gravity limits.

Suppose the measuring H distance is 1.2m, the density of oil is 0.7, and the density of water is 1.0. The pressure guiding pipe on the high and low pressure side is filled with water as a sealing liquid. Find the range of the differential pressure transmitter.

Solution:

Differential pressure at the lowest water level: P=(ρoil×g×H)-(ρwater×g×H)

=(0.7×9.8×1.2)-(1.0×9.8×1.2)=-3.528Kpa

Differential pressure at the highest water level: P=(ρwater×g×H)-(ρwater×g×H)

=(1.0×9.8×1.2)-(1.0×9.8×1.2)=0Kpa

The range of the transmitter is: -3.528Kpa to 0 Kpa

Quick calculation of range: (ρ water-ρ oil)×g×H=3.528Kpa

Note: This algorithm is only used for working conditions with obvious oil and water layers. It is undesirable if oil and water are miscible to form an emulsified quality.

Read more about: 7 Level Senors for Tank Level Measurement

Frequently

Asked

Questions

Related Products

Related Blogs

Extended reading: Water Tank Level Controller

Sino-Inst offers over 10 Solutions for Oil-water Interface Level Measurement. About 50% of these are interface liquid level meters, 40% is the level switches.

A wide variety of Solutions for Oil-water Interface Level Measurement options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Solutions for Liquid Level Measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.