Fluid Flow Measurement Devices

Fluid Flow Meters measure the amount of liquid, gas, or steam passing through the piping system. Most Fluid Flow Meters are designed to measure the speed of fluid flowing through pipes. They use this information and the internal cross-sectional area of the pipe to calculate the volume. Or the amount of mass of fluid passing through the system in a given period of time (that is, 50 gallons per minute).

Fluid flow meter principle

Principles of mechanics:

- Instruments that belong to this type of principle include differential pressure type and rotor type using Bernoulli’s theorem.

- Impulse type and movable tube type using the momentum theorem.

- Use the direct mass formula of Newton’s second law.

- Target type using the principle of fluid momentum.

- Turbine type using the angular momentum theorem.

- Vortex type and vortex street type using the principle of fluid oscillation.

- Pitot tube type and volume type, weir, trough type, and so on using total static pressure difference.

Principles of Electricity:

Instruments used in this type of principle include electromagnetic, differential capacitive, inductive, strain resistance, etc.

Acoustic principle:

Ultrasonic type is used for flow measurement using acoustic principles. Acoustic type (shock wave type) and so on.

Thermal principle:

There are calorimetric, direct calorimetry, indirect calorimetry, etc., which use thermal principles to measure flow.

Optical principle:

Laser type, photoelectric type, etc. are instruments that belong to this type of principle.

Based on physical principles:

Nuclear magnetic resonance, nuclear radiation, etc. are instruments that belong to this type of principle.

Other principles: There are marking principles (tracing principles, nuclear magnetic resonance principles), related principles, etc.

Extended reading: U-series Liquid Mass Flow Meter | Liquid-slurry flow measure

Fluid flow meter types

- According to the measurement objects, there are two categories: closed pipes and open channels.

- According to the principle of measurement, there are mechanical principles, thermal principles, acoustic principles, electrical principles, optical principles, atomic physics principles, etc.

- According to the purpose of measurement, it can be divided into total measurement and flow measurement. The meters are called total meter and flow meter respectively.

Liquid flow meters can be divided into: anti-corrosion flow meters. Liquid flow meters.. Differential pressure flow meters. Ammonia flow meters. Turbine flow meters. Electromagnetic flow meters. Vortex flow meters in fluid oscillating flow meters. Mass flow meters.

Hydraulic fluid flow meter

Industrial Hydraulic oil flow meter, also called hydraulic flow meter gauge. Hydraulic oil flow meters are inline flow meters for hydraulic oil flow measurement.

Sino-Inst offers Turbine, Mass flow, Oval gear, V-cone, Target, and Orifice flow meters for inline hydraulic oil flow. Features like: bidirectional, high pressure, analog, can be customized as customer need.

Extended reading: What Is Hydraulic Flow Meter?

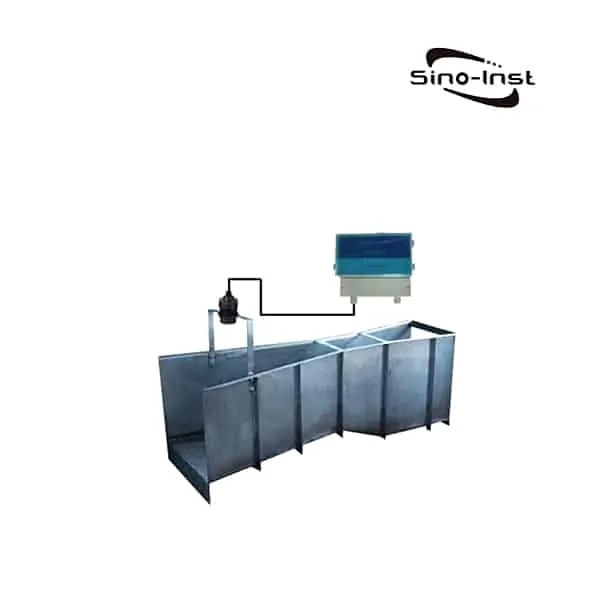

Ultrasonic fluid flow meter

The ultrasonic flow meter measures the liquid flow rate quickly and effectively. There are two types of ultrasonic flowmeter technology: Doppler frequency shift and transit time.

Transit time ultrasonic flow meter is most suitable for measuring the flow of cleaning liquid. Therefore, it is the most popular type of ultrasonic meter.

Doppler ultrasonic flow meter can measure the frequency difference of sound waves reflected from bubbles or particles in the airflow. It is suitable for aerated or dirty liquids.

Fluid mass flow meter

Fluid mass flow meter directly measures the mass flow of the medium passing through the flow meter. It can also measure the density of the medium and indirectly measure the temperature of the medium.

A flow measuring instrument that measures the mass flow in the pipeline. The measured fluid is under the condition that the pressure, temperature and other parameters change greatly. If only the volume flow is measured, the change in fluid density will bring about a large measurement error.

In positive displacement and differential pressure flowmeters, the density of the fluid to be measured may vary by 30%, which will cause an error of 30 to 40% in the flow rate.

With the improvement of automation level, many production processes have put forward new requirements for flow measurement. The chemical reaction process is controlled by the quality (not the volume) of the raw materials.

The heating and cooling effects of steam and air flow are also proportional to the mass flow.

The strict control of product quality, accurate cost accounting, and fuel control of airplanes and missiles all require precision. Therefore, the mass flow meter is an important flow measuring instrument.

You may like: High-Temperature Oval Gear Heating oil Flow Meter

Fluid Flow Meters Selection Guide

How to select the flowmeter?

It can be considered from five aspects. These five aspects are flow meter performance, fluid characteristics, installation conditions, environmental conditions and economic factors. The detailed factors in the five areas are as follows:

- Instrument performance: accuracy, repeatability, linearity, range, flow range, signal output characteristics, response time, pressure loss, etc.;

- Fluid characteristics: temperature, pressure, density, viscosity, chemical corrosion, abrasiveness, fouling, miscibility, phase change, electrical conductivity, speed of sound, thermal conductivity, specific heat capacity, isentropic index;

- Installation conditions: pipeline layout direction, flow direction, length of the upstream and downstream side of the test piece, pipe diameter, maintenance space, power supply, grounding, auxiliary equipment (filter, getter), installation, etc.;

- Environmental conditions: ambient temperature, humidity, electromagnetic interference, safety, explosion-proof, pipeline vibration, etc.;

- Economic factors: instrument purchase, installation, operation, calibration, maintenance, instrument service life, spare parts, etc.

The flowmeter selection steps are as follows:

- According to the fluid type and five consideration factors, the available instrument types are initially selected (there are several types for selection);

- Collect data and price information for the primary selection type. Prepare conditions for in-depth analysis and comparison;

- Use the elimination method to gradually concentrate on 1 or 2 types. It is necessary to repeatedly compare and analyze the five factors to finally determine the pre-selection target.

Frequently asked questions

Related fluid flow measurement devices

Related Blogs

Sino-Inst offers over 50 flow meter for flow measurement. About 50% of these are differential pressure flow meters, 40% is the liquid flow sensor, and 20% are Ultrasonic Level Transmitter and mass flow meter.

A wide variety of flow meters options are available to you, such as free samples, paid samples.

Sino-Instrument is a globally recognized supplier and manufacturer of flow measurement instrumentation, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.