64-80GHz FMCW Level Radar is a radar sensor for continuous level measurement of liquids. Sino-Inst also launched a radar level sensor operating at 76-81 GHz.

Sino-Inst offers a variety of Radar Level Sensors for industrial level measurement. If you have any questions, please contact our sales engineers.

Features of 76-81GHz FMCW Level Radar

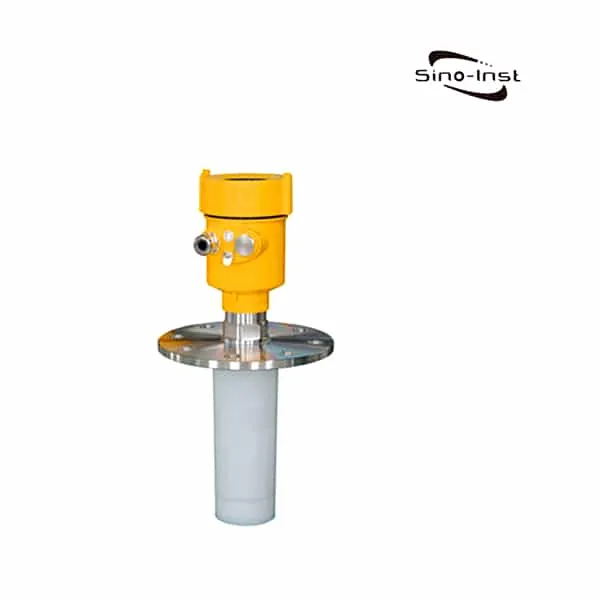

The LM78xx series is an FMCW radar operating at 76-81 GHz, which has a maximum measuring range of 120m and a minimum blind zone of 8cm. It supports 4-wire and 2-wire applications. Higher operating frequency and shorter wavelengths make it ideal for solid applications, including those with extreme dust and high temperature to + 200℃.

The radar consists of an electronic circuit coupled to a lens antenna and flange for quick and easy positioning.

The main benefits of using 78 GHz over devices using lower frequency are:

- Based on the self-developed CMOS millimeter wave RF chip, a more compact RF architecture, a higher signal-to-noise ratio, and a smaller blind zone are realized.

- 5GHz working bandwidth means higher measurement resolution and accuracy.

- 3°antenna beam angle, so the interference in the environment has less impact on the instrument, and the installation is more convenient.

- Shorter wavelength yields good reflection properties on sloped solids, so aiming towards material angle of repose is usually not necessary.

- Support remote debugging and remote upgrading to reduce the cost of field personnel.

Communication and Programming

LM78XX supports 485 bus protocol (4-wire), serial-port (2-wire) protocol, and hart (2-wire) protocol. It is very easy to install and configure via an optional graphical local display interface on a PC. Or you can modify the built-in parameters either locally via the pushbuttons. Or you can use a cell phone to control LM78xx via Bluetooth.

Extended Reading: Case: High Temperature Radar Level Transmitter for Melted Salt-Solar Photovoltaic Power Station

Specifications of 76-81GHz FMCW Level Radar

| Frequency | 76GHz ~ 81GHz, 5GHz FMCW bandwidth |

| Measuring range | LM78x0: 0.3 m ~ 60m LM78x1: 0.08m~30m LM78x2: 0.6m ~ 120m |

| Measurement accuracy | ±1mm |

| Beam angle | 3°/8° |

| Minimum measured dielectric constant | >=2 |

| Power | 15~28VDC |

| Communication | LM782x: MODBUS LM783x: HART/Series |

| Signal output | LM782x: 4 ~ 20mA or RS-485 LM783x: 4~20mA |

| Fault output | 3.8mA, 4mA, 20mA, 21mA, hold |

| Field operation / programming | 128 × 64 dot matrix display / 4 buttons PC software Bluetooth |

| humidity | ≤95%RH |

| Enclosure | Aluminum alloy, stainless steel |

| Antenna type | Lens antenna/anti-corrosive antenna/flange isolated by quartz |

| Process temperature | T0:-40~85℃; T1:-40~200℃; T2:-40~500℃; T3:-40~1000℃ |

| Process pressure | -0.1~2MPa |

| Product Size | Ø100*270mm |

| Cable entry | M20*1.5 |

| Recommended cables | AWG18 or 0.75mm² |

| Protection class | IP67 |

| Explosion-proof grade | ExdiaIICT6 |

| Installation method | Thread or flange |

| Weight | 2.480Kg/2.995Kg |

| Packing box size | 370*270*180mm |

Extended reading: FMCW Radar Level Transmitter 120GHz

64-80GHz FMCW Level Radar Applications

Application area:

Special advantages are the small process fittings for small tanks or tight spaces. The very good signal focusing allows use in vessels with many internal installations.

LM78 series FMCW Level Radar Applications

It is suitable for large range, high dust, steam condensation, mixing, narrow installation space, and occasions with high precision and blind zone requirements.

Applicable working conditions:

- Intermediate silo

- Warehouse

- hopper

- Storage tank

- Process tank

- Mixing tank

Extended Reading: Influence of Dielectric Constant on Liquid Level Measurement | Radar-Guided Wave Radar Level Meter

Download Datasheet

More Featured Non-Contacting Radar Level Measurement

Sino-Inst offers Alternative to 64-80GHz FMCW Level Radars for level measurement.

A wide variety of 64-80GHz FMCW Level Radars options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of radar level measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.