Magnetostrictive level gauge application tutorial. Just one article to help you understand !

This article introduces the installation method and typical application of magnetostrictive level gauge in depth. Help you fully understand the structure and selection of magnetostrictive level gauges.

Sino-Inst offers a variety of Magnetostrictive level gauges for level measurement. If you have any questions, please contact our sales engineers.

Magnetostrictive level gauge measurement principle

Substances expand and contract with heat. In addition to heating, magnetic and electric fields can also cause the size of objects to elongate or shrink. Under the action of an external magnetic field, the size of a ferromagnetic substance elongates (or shortens). After the external magnetic field is removed, it returns to its original length. This phenomenon is called magnetostriction (or effect).

Based on the principle of magnetostriction, a magnetostrictive wire is installed in the non-magnetic probe, and the sensor is connected to one end of the magnetostrictive wire. The main control electronic unit sends a narrow electromagnetic pulse to the magnetostrictive line, and the electromagnetic pulse is conducted along the magnetostrictive line.

When the magnetic field generated by the pulse interacts with the magnetic field generated by the magnet in the float marking the liquid level/interface, a torsional stress wave will be generated on the magnetostrictive line, which will return to the sensor along the magnetostrictive line. Convert the captured return wave into an electronic pulse signal and send it back to the main control electronic unit.

The main control electronic unit accurately measures the time interval between the emission pulse and the return pulse through a precision circuit, and calculates the position of the float, that is, the height of the liquid level/interface.

Magnetostrictive level gauge application range

◆Power plant: reservoir, waste gas purification tank, fuel tank, etc.

◆Oil field: crude oil or product oil storage tank, three-phase separator, settling tank, sewage tank (pool), etc.

◆Petrochemical: oil pipelines, distillation towers, concentration tanks, liquefied gas tanks, ammonia tanks, oil refineries, etc.

◆Chemical industry: distillation tower, ammonia tank, toxic liquid tank, etc.

◆Water and water treatment: reservoirs, sewage tanks, water treatment tanks, sedimentation tanks, digestion towers, etc.

◆Others: food, pharmaceutical, environmental protection, papermaking and other industries

Read more about: Common Types Of Heating Oil Tank Level Sensors

Features of magnetostrictive level gauge

◆Multi-function: can measure liquid level and interface position separately or at the same time

◆High precision: measurement accuracy ±0.8mm or 0.01%FS (the larger one)

◆Wide scope of application: flexible and diversified installation methods.

◆Output mode: on-site instructions and remote electrical signal output

◆Low power consumption: two-wire loop 4-20mA output, LCD display

The principle and characteristics of the magnetostrictive level gauge are briefly introduced above.

The following content of this article will give a detailed introduction to the application of magnetostrictive level gauges. I hope you have a deep understanding of the installation and use of magnetostrictive level gauges on site after reading this article.

1.Probe form of magnetostrictive level gauge

Magnetostrictive level gauges usually have rod probes and cable probes. With different floats, the liquid level or interface can be measured.

①The probe is a rod type probe, which can measure liquid level or interface with different floats. The maximum length is 4m.

②The probe is a rod probe, which can be equipped with double floats to measure the liquid level and interface at the same time. The maximum length is 4m.

③The probe is a cable probe, which can measure liquid level or interface with different floats. The maximum length is 20m.

2.Installation method and structure of magnetostrictive level gauge

The magnetostrictive level gauge can be combined with the outer pontoon or the outer pontoon + magnetic flap into several installation methods. It is not only easy to install and maintain, but also can cooperate with the on-site flip display. Realize the on-site and remote dual output. The probe has multiple parameters to choose from. Including: installation type, connection method, probe installation type, end structure, etc.

①Installation of probe rod and magnetic flap

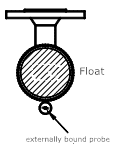

◆For the probe structure that is attached outside the probe. The probe rod is usually fixed on the opposite side of the connecting structure, as shown in the figure below.

◆When a magnetic flap is needed, the magnetic flap is usually fixed on the opposite side of the connection structure. At this time, the probe rod will move to any position on the left and right sides of the float, as shown in the figure below.

② Magnetostrictive level gauge probe top insertion + side/side installation method

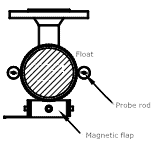

The picture above shows the most commonly used side mounting: side-to-side mounting (the probe mounting type is for inserting the top of the probe)

Figure a. Connection mode: flange connection, bottom structure: end cover + plug

Figure b. Connection method: chuck connection, bottom structure: blind flange

Figure c. Connection method: welding, bottom structure: short pipe + drain valve

Note: There is no necessary correspondence between the connection mode and the end structure.

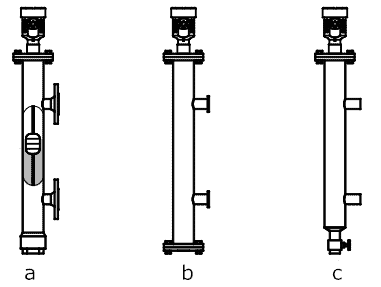

③The bottom of the magnetostrictive level gauge probe is inserted + side/side installation method

The probe installation types in the above figure are all “insert installation at the bottom of the probe”.

Figure d. Top structure: end cover + plug

Figure e. Top structure: blind flange

Figure f. Top structure: closed

This structure is not conducive to sewage and maintenance. Therefore, when using the probe upside down, it is recommended to install the probe upside down and externally bound.

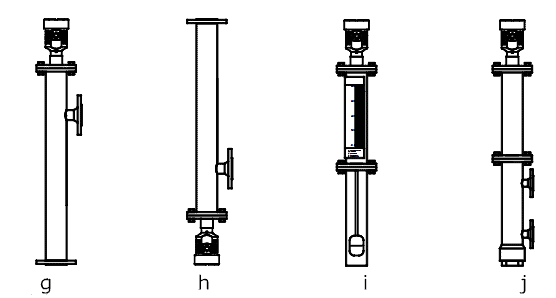

④Figure g shows the magnetostrictive level gauge probe top insertion + top/side installation

⑤Figure h shows the bottom insertion + side/bottom installation of the magnetostrictive level gauge probe

⑥Figure i shows the magnetostrictive level gauge probe top insertion + top-mounted installation + magnetic flap display

⑦Picture j is the magnetostrictive level gauge probe top insertion + side/side installation + magnetic flap display

Note: The two installation methods of ⑥ and ⑦ are suitable for occasions where the measurement position is low.

⑧Figure k Magnetostrictive level gauge probe upside-down external binding + bottom-mounted plug-in installation + magnetic flap display

⑨Figure l Magnetostrictive level gauge probe upside-down external binding + side/side installation + magnetic flap display

Note: ⑧ and ⑨ installation methods The probe installation type is the probe inverted and externally bound. These two installation methods are suitable for occasions with higher measuring positions. The end cover + plug structure or blind flange structure is selected for the bottom, which is conducive to sewage and maintenance.

The above pictures are all attached to the outside of the probe.

⑩Figure m shows the probe front-mounted external binding installation

⑪Figure n shows the probe front-mounted external binding installation

⑫Figure o shows the probe upside-down and external binding installation

The manufacturer will choose the formal installation type according to the top structure

The picture above is a schematic diagram showing the magnetostrictive level gauge with a magnetic flap.

⑬Picture p is side-mounted, side-to-side mounted, with the probe top inserted

⑭Figure q shows two views of side-mounted, side-to-side installation, the probe top is inserted and installed, and the bottom end cover + plug structure

⑮Figure r is a schematic diagram of the side-mounted, side-to-side mounted, the probe is mounted with an external binding type, the top is closed, and the bottom drain valve structure is schematic.

Typical tank application of magnetostrictive level gauge

1.Magnetostrictive liquid level gauge is used for liquid level measurement of agitated and foamed containers

When applied to occasions with stirring and foam, liquid level fluctuations and foam will affect the measurement. At this time, it is recommended to use a top-mounted probe or add a protective tube to the probe.

2.Magnetostrictive level gauge is used for liquid level measurement of small-sized containers

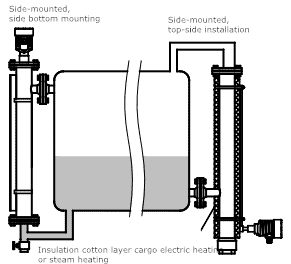

◆When the container to be measured is small, the use of side-to-side connection will reduce the effective measurement range. At this time, the side-to-bottom or top-to-side connection can be used to effectively increase the measurement range.

◆When the process temperature is high, you should pay attention to heat preservation, as shown in the figure on the right, you can use insulation cotton for heat preservation, or use electric heat tracing and steam heat tracing for heat preservation.

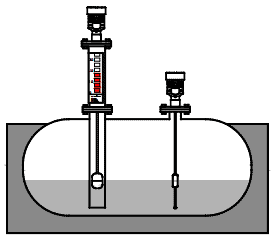

3.Magnetostrictive liquid level gauge is used for liquid level measurement of buried tank

The “buried tank” here includes a container whose main body is buried in the ground and a container whose sides are covered and cannot be installed with meters. For the measurement of this type of container, simple applications can use rod probes and cable probes. If you need on-site display, you need to use a magnetic flap + top-mounted plug-in installation type

4.Magnetostrictive liquid level gauge is used for liquid level measurement of ceiling tanks and suspended tanks

When the location of the container to be measured is high, it is difficult to install, debug, and maintain the instrument, and it is difficult to display on-site. It is recommended to use magnetic flap + bottom-mounted plug-in installation type. Or magnetic flap + bottom-mounted side-side mounting type.

Magnetostrictive level gauge installation methods and professional knowledge of typical applications are shared here.

I don’t know if you have noticed: whether there is a sudden sense of clarity when selecting the magnetostrictive level gauge based on the on-site working conditions and these installation and application examples. The selection is simply to convert the legend to the response model!

Magnetostrictive Level Gauge/Sensors for Sale

Sino-Inst offers over 10 Magnetostrictive level gauges for level measurement. About 50% of these are Magnetostrictive liquid level meters, 40% is the tank level sensor.

A wide variety of Magnetostrictive level gauges options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Magnetostrictive level measurement instrumentation, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.