Boiler Drum Level Measurement is very important and necessary in major factories. Drum level is an extremely important control parameter. It is an important guarantee for the production of high-quality steam. It is also directly related to the safe operation of the steam drum.

Excessive liquid level will cause the steam-water separation of the steam drum. Increase the moisture carried by the steam. Deteriorating steam quality. It can cause water to enter the turbine, and even damage its blades in severe cases. If the liquid level is too low, there is less water in the drum. Water vaporizes faster. Causes the downpipe to carry steam. Cause the steam drum to burst or explode.

Therefore, it is important to choose a suitable and safe liquid level sensor to measure Boiler Drum Level.

Why is Boiler Drum Level Measurement important?

In the boiler evaporation equipment, the boiler drum is an important part. The natural circulation loop of the boiler is composed of it, the upper header, the lower header, the lead-out pipe, the descending pipe and the water cooling wall. How the boiler drum level is controlled will affect the following aspects.

When the liquid level of the boiler drum is too high. The space where the steam is located is reduced. This results in increased water carryover in the steam. Causes the steam quality to deteriorate. This is one of them. Second, the water level is too high, and the superheater pipe is easy to accumulate salt scale. The tube is overheated and damaged.

The above two situations will occur when the water level is too high. What happens when the steam drum is full of water?

When the steam drum is full of water, there will be a lot of water in the steam. Severe hydraulic shock to steam lines.

The boiler drum water level is too high or too full. So is it too low?

The answer is of course no.

When the water level in the drum is too low, the water circulation will be disrupted. The water wall will exceed the usual temperature and overheat. If the water level is low to a certain extent, there is a serious water shortage. The device is likely to be severely damaged. even lead to accidents.

From the above content, it can be seen that the high and low water level of the boiler drum will have a certain impact on the safe operation of the boiler. In severe cases, it may even affect the safe operation of the unit. Therefore, it is very important to control the liquid level of the boiler drum. The use of liquid level gauges for liquid level measurement is also an inevitable result.

Liquid level data, seemingly unimportant, is actually very important. So no matter what industry, you must understand your own working conditions when choosing a liquid level sensor. Select the liquid level sensor according to the working conditions, so as to choose the appropriate one.

Extended reading: Hydrostatic Level Measurement

Current Situation of Drum Level Measurement

At present, from the basic principle of drum level measurement. The widely used are mainly based on two principles of connecting pipe type (static pressure) and differential pressure type. Drum level measurement instruments mainly include differential pressure level transmitters, Displacer Level Transmitters and guided wave radar level sensors.

To sum up, due to the complexity of the measurement object of the liquid level in the drum, the uncertain factors in the actual operation and the large measurement error, the measurement of the liquid level sensor in the drum often has a large deviation.

Guided wave radar liquid level measurement is a brand-new measurement technology. It overcomes the shortcomings of liquid level measurement instruments such as differential pressure type, float type, and electrical contact. It is a brand-new liquid level measurement device.

Guided Wave Radar Level Transmitter

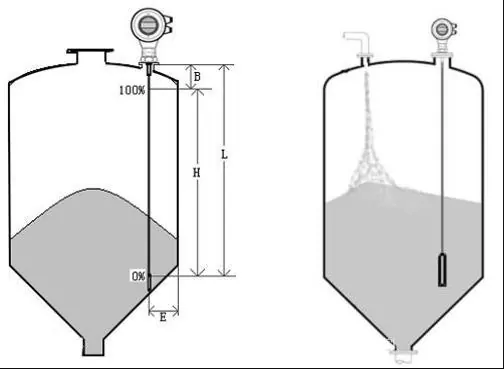

Guided wave radar level transmitter uses guided wave radar (GWR) technology. Based on the reflection of microwave on the surface medium. Through the probe, continuous level measurement of liquid and solid levels is completed.

A guided wave radar level transmitter is also called a wave-guided radar level sensor. They can measure both levels and the interface between two media. Through probe rod or cable, complete level contact types continuous level measurement. Such as Coaxial Probe Guided Wave Radar Level Transmitter. This is different from ultrasonic level measurement, which is non-contact measurement. A guided wave radar level transmitter is often used for tank level measurement. Including liquid and solid. Output 4~20mA/HART, so as to measure and control the level during production.

Read more about: Condensate Flow Meter-Steam Condensate Flow Meter|Types & Selection Guide

Guided wave radar level transmitter measures drum level

A new type of Guided wave radar level transmitter is used to measure the liquid level of the steam drum of a certain device. The level gauge is certified as a limiting device for high temperature water (HW) and low temperature water (LW) containers. Complies with EN12952-11 and EN12953-9 (TUV certified) standards.

Guided wave radar level transmitter with GPC function technology. Improve the accuracy and reliability of the Guided wave radar level transmitter in high temperature and high pressure environment.

GPC technology

Under high temperature and high pressure conditions, the propagation speed of electromagnetic wave signals in the vapor above the medium (polarized medium) will decrease. At this time, the liquid level value measured by the radar will decrease.

Use guided wave radar with gas phase automatic compensation. Guided wave radar produces a reference reflection within the distance from the flange (measurement reference point), which varies along the rod probe.

Under normal temperature and pressure. The electromagnetic wave has two reflected echoes at the compensation reference end and the liquid level reflecting surface. The measurement is accurate at this time. At this time, the reference distance (the distance from the measurement reference point to the reference rod) is calibrated.

At high pressure, due to the polarization effect of the gas. At this time, the measured distance (the distance from the measurement reference point to the liquid level) has a large deviation from the actual value of the liquid level. if not compensated. Then there will be a large error in the measurement value.

The measured value is compensated by converting the reference reflection.

The calculation formula is: compensation distance = reference distance × (measured distance/measured distance). An accurate actual liquid level value can be obtained.

Application

The steam drum of the boiler plant is the main part of the steam production system.

Use the high temperature heat in the flue gas section of the reformer and the high temperature waste heat of the reformer gas at the furnace outlet. Produce 10.5MPa high pressure steam.

Part of it participates in the reaction as the steam distribution in the process. The other part is sent to the high-pressure steam pipe network to realize the comprehensive utilization of thermal energy and improve the operation efficiency of the device.

Because the traditional measurement can not meet the measurement requirements well. It is necessary to choose other products to replace.

Due to the importance of the steam drum to the boiler plant. To measure the liquid level of the steam drum, three measuring instruments are designed and used: Guided wave radar level transmitter and differential pressure liquid level level transmitter.

Measured by example. At high temperature, the measurement error of ordinary guided wave radar (without GPC) is as high as 18%. With GPC, the measurement error is only 2%.

The measurement data of the GPC guided wave radar level gauge at high temperature is relatively stable and true.

Therefore, it is a perfect combination of guided wave radar technology with GPC and advanced signal processing technology. This makes the guided wave radar level gauge with GPC an ideal solution for level measurement in steam and turbulent boiling conditions.

Extended reading: Vortex Steam Flow Meter

Featured Guided Wave Radar Level Transmitters

Related Level Measurement Blogs

Sino-Inst offers over 10 GWR Corrosive Liquid Chemical Level Sensors for level measurement. About 50% of these are Guided Radar level meters, 40% is the tank level sensor.

A wide variety of GWR Corrosive Liquid Chemical Level Sensors options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Guided Wave radar level measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.