A capacitive pressure transducer also called a Capacitance pressure transmitter or a Capacitance pressure sensor. The capacitive type pressure transmitter is a differential pressure type sensor.

What is the capacitive pressure transducer?

The capacitance pressure transmitter is a pressure measurement device, which converts an applied pressure into a current signal, Like 4-20mA.

A pressure transducer is a device that measures the pressure of a fluid, indicating the force the fluid is exerting on surfaces in contact with it.

Pressure transducers are used in many control and monitoring applications, such as flow, airspeed, level, pump systems, or altitude.

A pressure transducer consists of two main parts: an elastic material that will deform when exposed to a pressurized medium. And an electrical device that detects the deformation and converts it into a usable electrical signal.

The elastic material can be formed into many different shapes and sizes, depending on the sensing principle and range of pressures to be measured.

This often involves a diaphragm combined with an electrical device, that uses a resistive, capacitive, or inductive principle of operation.

Featured Capacitive pressure transducers

How does a capacitance pressure transducer work?

Capacitive Pressure Transducer Working Principle

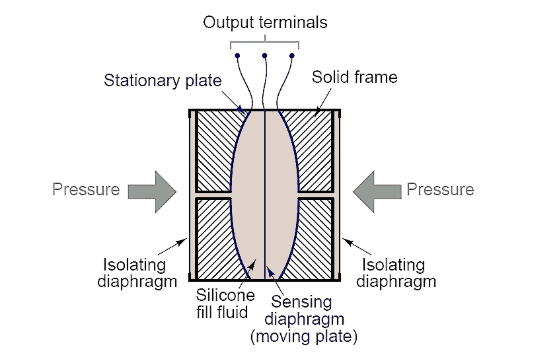

A variable capacitance pressure transducer has a capacitive plate (diaphragm), and another capacitive plate (electrode) fixed to an unpressurized surface. With a gap of a certain distance between the diaphragm and the electrode.

A change in pressure will widen or narrow the gap between the two plates, which varies the capacitance.

This change in capacitance is then converted into a usable signal.

Capacitive Pressure Transducer Working Principle:

– A linear change in capacitance with changes in the physical position of the moving element, may be used to provide an electrical indication of the element’s position.

The capacitance is given by:

C = Aε/d

C – Capacitance between two conductors

A – Area of overlapping between those conductors

d – Distance separating the conductors

ε – Dielectric permittivity of the insulating medium

The permittivity of the medium and the area of overlapping will be constant in this case, the only varying parameter. In this case, is the distance between the conductors which varies when the pressure varies, which changes the capacitance.

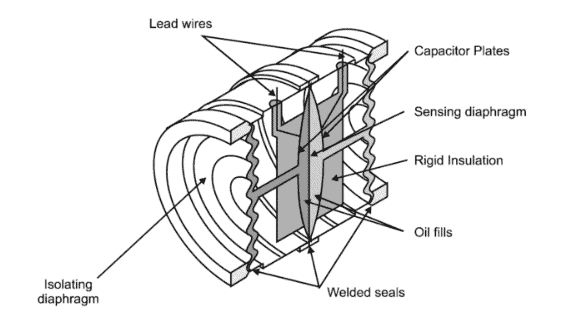

So the pressure variation results in the capacitance variation. Our capacitance pressure sensor is shown below. Just like A Rosemount capacitance pressure sensor:

- capacitance pressure sensor

- Rosemount capacitance pressure sensor

The capacitance chamber is isolated from the process with an isolation chamber.

The pressure applied at one side. As the pressure at the high-pressure side increases the isolating diaphragm gets pushed toward the metal frame. Transferring its motion to the sensing diaphragm via the fill fluid.

The fill fluid will be oil.

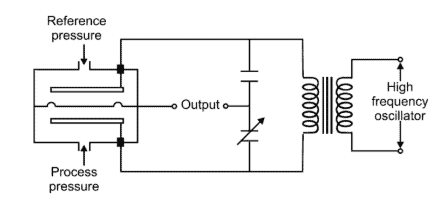

A capacitance detector circuit connected to this cell uses a high-frequency AC excitation signal to measure the difference in capacitance between the two halves. Translating that into a DC signal ultimately becomes the signal output by the instrument representing pressure.

The simple capacitance detector connection with the electrical circuit is shown below:

Advantages of Capacitive Pressure Transducer:

- Inaccuracy 0.01 to 0.2%

- Linearity

- Fast response

- Range of 80Pa to 35MPa

Disadvantages of Capacitive Pressure Transducer:

- Temperature sensitivity

- Stray capacitance problem

- Vibration

- Limited overpressure capability

- Cost

Read more What is a diaphragm seal?

What does a pressure transducer do?

A pressure transducer is a measuring device which converts an applied pressure into an electrical signal.

Generally, a pressure transducer consists of two parts, an elastic material that deforms under the application of pressure. And an electrical part which detects this deformation.

Extended Reading: 4-20ma pressure transducer wiring diagram

Capacitive pressure sensor applications

Types of Pressure Sensors:

There are different types of pressure transducers based on their design.

These sensors can come in several shapes and sizes, but the technology inside can also differ.

There 4 main types of pressure sensor based on this:

- Strain Gauge Pressure Transducers

- Capacitance Pressure Transducers

- Potentiometric Pressure Transducers

- Resonant Wire Pressure Transducers

Know more about Industrial Pressure Sensors

How much does it cost a pressure transducer?

There are a number of factors that will impact the price of a pressure transducer.

The biggest differentiator is whether you can use a standard, off-the-shelf pressure transducer, or if you need a custom pressure transducer.

For an off-the-shelf pressure transducer, pressure transducer prices will be most affected by the level of accuracy required for your application.

The more accurate, typically the more expensive the pressure transducer.

To learn more about the pricing of custom pressure sensors click here.

Related Products

Low pressure transducers for air and non-corrosive gases low pressure measurement. 0 ~ 2.5kPa to 0 ~ 30kPa measurable.

Sanitary Pressure Transmitter, also called tri clamp pressure transmitter,

is the pressure transducer with the flush diaphragm (flat membrane) as the pressure sensor.

The 4-20mA/ Voltage Pressure Transducer,

also called pressure transmitter 4-20mA,

is a pressure sensor with4-20ma/Voltage output.

High Temperature Pressure Sensor for pressure measurement of high temperature gas or liquid. Such as steam pressure. High temperature up to 800 ℃.

Combined pressure and temperature sensor for Simultaneous measurement.

Thermocouple types: J, K, E type or PT100 platinum resistance.

Absolute pressure transmitter with 4-20mA output for measuring pressure with absolute type reference. Absolute pressure (AP) transmitter is a measure of the ideal (complete) vacuum pressure.

Hydrostatic pressure transmitter is used for fluid hydrostatic pressure measurement. With working static pressure up to 32Mpa, for liquid, gas or steam .

A gauge pressure (GP) transmitter compares a process pressure against local ambient air pressure. Gauge pressure transmitters have ports to sample the ambient air pressure in real-time.

Gauge pressure (GP) transmitters compare process pressure with local ambient air pressure. Gauge pressure transmitters have ports for real-time sampling of ambient air pressure.

In addition to pressure measurement, capacitive technology is also used in liquid level measurement. Read more about: Capacitive Level Measurement Principle.

Sino-Instrument offers over 50 Capacitive pressure transducers.

About 50% of these are 4-20ma Low-Pressure Transducers, 40% are Differential Pressure Gauge.

And 20% are Diaphragm Seal Pressure transmitters, 20% are 4-20ma differential pressure transmitters.

A wide variety of Capacitive pressure transducers options are available to you, such as free samples, paid samples.

Sino-Instrument is a globally recognized supplier and manufacturer of Low-Pressure Transducers, located in China.

The top supplying country is China (Mainland), which supply 100% of Capacitive pressure transducers respectively.

Capacitive pressure transducers products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.