Choosing the right diesel fuel level sensor can be crucial for your business. The diesel fuel level sensor is used on various diesel tanks to detect the diesel level and then display the liquid level. It can also be converted into 4-20mA or switch signal. Used to monitor and control other instruments. There are so many choices in the market, ultrasonic level sensor, radar level meter, etc. Which is the most suitable?

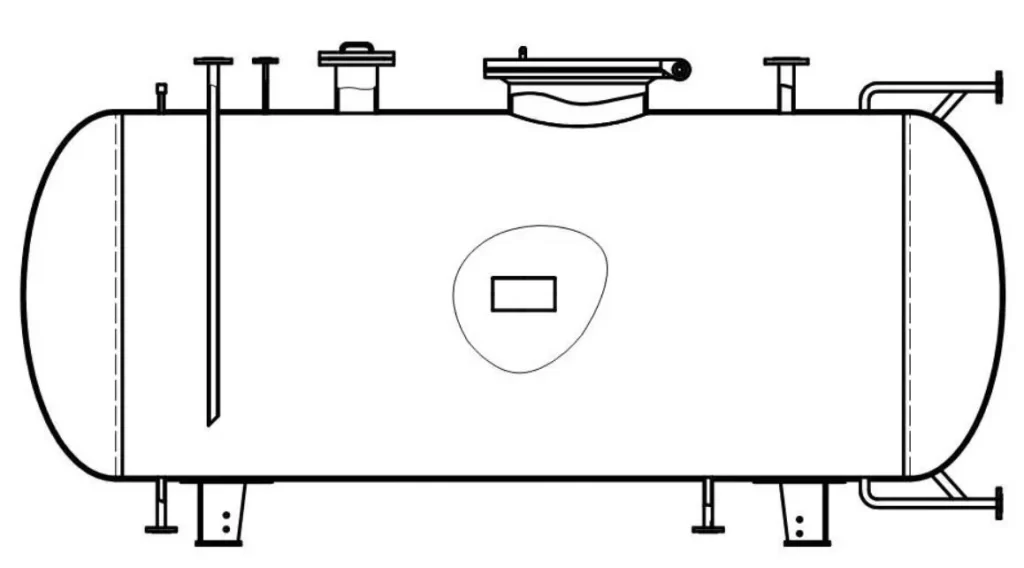

Step 1. Get to know your tank

To choose a suitable Diesel Fuel Level Sensor, you must first understand the conditions of the tank.

How can we understand your tank? Simply put, a list can be compiled.

- Tank size (preferably with a sketch of the tank)

- The installation position of the tank. For example, it is a buried tank, an underground tank, or a vehicle-mounted tank.

- Tank material

- Density of Diesel Oil

- Temperature and pressure

- Installation position and installation dimensions of Diesel Fuel Level Sensor

With the above conditions, Sino-Inst, as the supplier of Diesel Fuel Level Sensor, can know the condition of the tank.

Read more about: Ultrasonic Tank Level Sensors for Tank Level Monitoring

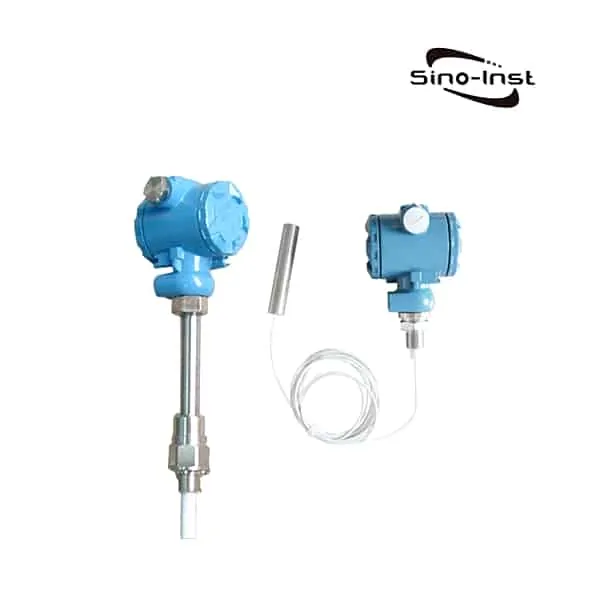

Step 2. Diesel Fuel Level Sensor Types

Diesel fuel level sensors are devices used to measure the level of diesel fuel in a tank.

There are several types of diesel fuel level sensors, including:

Step 3. Measurement Needs

OK. Next, we can sort out our needs, and then match the appropriate Diesel Fuel Level Sensor.

Low Cost

If you are looking to get the right Diesel Fuel Level Sensor at low cost. Then you can choose one from Float Level Sensors and Pressure Guided Submersible Level Transmitter.

Small tanks, such as 2 meters or 3 meters high. Float Level Sensors can be used.

Large tanks, such as 15 meters, 20 meters. You can use the Pressure Guided Submersible Level Transmitter.

High Accuracy

If you need the highest measurement accuracy. Then Radar Level Transmitters is a good choice. The 80GHz Radar Level Meter has an accuracy of up to ±1mm.

- Maximum measuring range of 120m and a minimum blind zone of 8cm;

- 3°antenna beam angle;

- Suitable for small water tanks or small process accessories in narrow spaces.

- Good signal focusing ability can be used for containers with many internal installations.

- Measurement accuracy:±1mm

high temperature and high pressure

High temperature and pressure

If you want to measure under high temperature or high pressure conditions. For example, 200 degrees Celsius. Or 10MPa.

Then you can choose the appropriate one from Capacitive level sensor, Radar level meter, and Magnetostrictive level transmitter.

contact measurement

If you specified that contact measurement is optional. Then you can choose from Float Level Sensors, Pressure Guided Submersible Level Transmitter, Magnetostrictive Level transmitter, capacitive level sensor, etc.

non-contact measurement

If you specify non-contact measurement. Then you can choose the explosion-proof ultrasonic level meter. Or radar level meter.

Output switching value

If you need to measure the diesel oil level, then output the switch signal for the switch of the pump or other components.

Then you can choose the float level switch. Or configure secondary instruments for ordinary liquid level meters, Output switching value.

The tank cannot be opened

If the tank cannot be opened. Then you can choose an externally attached ultrasonic level sensor.

The sensor can be directly attached to the bottom of the tank. easy installation.

- HS-2000 Ultrasonic Tank Level Sensor-External Mounted

- HS-ULC Ultrasonic Level Switch-External Mounted

- HS-ULC-Pro Ultrasonic Non-contact Liquid Level Controller

- Ultrasonic Oil Level Sensor-External Paste-Truck Fuel Tank

Large range

If the tank is larger. The height exceeds 15 meters. Then it is recommended to choose the radar level meter. Or Stainless Steel Level Sensor-Pressure Guided Submersible Level Transmitter.

oil-water interfac

If your tank is mixed with oil and water, it is the oil-water interface that needs to be monitored. Then you can choose: capacitive liquid level sensor or magnetostrictive liquid level transmitter.

Oil-water Interface Level Measurement Guide

Tank volume monitoring

Most of our liquid level sensors can output liquid level signals, such as 4-20mA signal, 0-10V signal, RS485 and so on.

However, the liquid level transmitter alone cannot calculate the liquid volume of tanks of different sizes. It’s too complicated. A separate recorder is required to calculate it.

Combined with Sino-Inst’s volume recorder. It can collect, display and convert the liquid level of various regular and irregular tanks in the industrial field into the corresponding tank volume. It is suitable for monitoring, controlling and collecting various process parameters.

Monitoring liquid volume solutions.

We simply enumerate our common measurement needs here, based on our experience.

If you have other measurement needs, you can contact our engineers for consultation.

Featured Diesel Fuel Level Sensors

Read more about: Factors To Consider When Selecting A Capacitive Level Sensor

More Tank Level Measurement Solutions

Choosing the right diesel fuel level sensor is critical for the smooth operation and maintenance of your diesel-powered machinery or vehicle.

By considering factors such as compatibility, accuracy, type of sensor, material, and brand, you can ensure that you select the most suitable diesel fuel level sensor for your specific needs.

If you don’t know which Diesel Fuel Level Sensor you should choose. Then you can contact our sales engineers.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.