Cooling Tower Level Sensors refer to a type of level meter that can be used to measure the water level of cooling towers. Cooling Tower Level Sensors are an important part of the cooling tower’s cooling function. The cooling tower liquid level control system is mainly used to control the cooling water level in the cooling tower to maintain it within a reasonable range at all times. And it can realize real-time monitoring of liquid level and abnormal alarm function. To ensure that it will not cause high temperature failure or damage to the air compressor.

Cooling Tower Water Basins

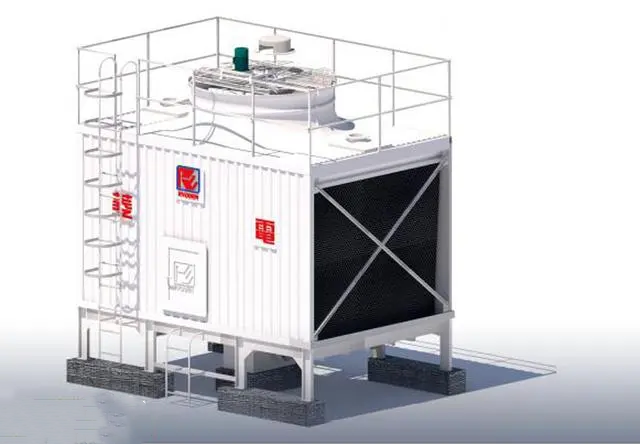

A cooling tower is a heat exchange system that brings air and water into direct contact to lower the water temperature.

To achieve this, water is continuously pumped to the top of the tower. There it flows through a series of baffles, mixing with air. And collected in the pool directly below the tower or the sump next to the tower. As heat and water escape from the tower through evaporation, additional water must be added to the system periodically.

Cooling towers come in many sizes, from rooftop systems to building size and beyond. A typical birdbath is open to the air and has a depth of 4 feet or less. Made of fiberglass, metal or concrete. The capacity is large enough to hold all the water in the system.

Cooling towers have two basic control systems, one for adding liquid to the pool. The other is used to turn the water recirculation system on or off. The main requirements of this application are to monitor the fluid level, automatically fill the basin and prevent the system from drying out.

At present, cooling towers generally use packed towers. If the tower liquid level is too high, it may easily cause:

- The dehydration effect of the cooling tower is not good;

- System pressure fluctuation increases;

- The porcelain ring in the tower is easily broken;

- Increase the workload of each water outlet.

Cooling tower water level monitoring and control system

If there is a new cooling tower now. A water level monitoring and control system needs to be established. The following design points can be considered. This is all based on our Sino-Inst’s years of experience in providing liquid level measurement services.

- Identify goals and needs:

- Do you only need to monitor the liquid level, or do you also need to control the liquid level?

- What are your liquid level accuracy needs?

- Are there special temperature, pressure or fluid property requirements?

- Choose the right Cooling Tower Level sensor:

- Based on the previous discussion, you might choose ultrasonic, Hydrostatic, or capacitive sensors as they are suitable for a wide range of applications and provide continuous level measurement. We discuss these techniques in detail below.

- Installation location:

- Ensure the sensor is optimally positioned to accurately measure the entire liquid level range.

- Output and communication:

- Choose a sensor with a standard output (e.g. 4-20 mA) that can be easily integrated into existing control systems.

- Consider using modern communication protocols such as Modbus or HART for remote access and debugging.

- Level Control:

- If level control is required, you may choose to use a solenoid valve or pump to increase or decrease the liquid.

- Controllers can automatically turn these devices on or off based on set points, ensuring liquid levels remain within the desired range.

- Security and Alarm:

- Set high and low level alarms to prevent the system from overloading or drying out.

- Consider using a redundant system to ensure backup level measurement in the event of a primary system failure.

- System verification and calibration:

- After the system is started, a full range of liquid level measurements are taken to ensure that all components are functioning properly.

- Calibrate the sensor regularly to ensure measurement accuracy.

- Maintenance and monitoring:

- Check all equipment regularly to ensure there is no wear or damage.

- Consider using a remote monitoring system to check fluid levels and system status from any location.

Hopefully this blueprint will provide a good starting point for your cooling tower level monitoring and control system. If you have any specific questions or need further guidance, please let me know!

cooling tower level sensors technology

Alright. Now you know the parameters of your cooling tower, including: pressure, temperature, liquid level range, installation location and installation dimensions, etc. Now you can start choosing the appropriate cooling tower level sensors.

Below are some recommended level measurement technologies that can be used for cooling tower water level measurement based on our experience at Sino-Inst.

Of course, if you want to buy the Best cooling tower level sensor, you must choose it based on the actual cooling tower parameters.

If you don’t know how to choose, please provide the parameters to our Sino-Inst sales engineers. We will provide you with a selection quote.

Below are the commonly used cooling tower level sensors supplied by our Sino-Inst.

Featured Cooling tower level sensors

FAQ

Implement cooling tower level control

After choosing the appropriate Cooling tower level sensors. We need to set up the cooling tower water level control.

The control of cooling tower water level is a key link to ensure the stable operation of cooling tower. The correct water level ensures cooling efficiency while also avoiding equipment downtime due to lack of water. The following is an introduction and guidance on how to achieve cooling tower water level control:

Connect and control equipment:

Cooling Tower Level sensors typically output a 4-20 mA current signal, which can be connected to a local controller or central control system. These control devices can be PLC, SCADA, DSC or independent level controllers. Any control device will do as long as the device can accept a 4-20 mA current signal.

Configuration operation scope:

The operating range of the controller needs to be programmed according to the measurement span of the Cooling Tower level sensor. Also, consider that the sensor’s 4 mA set point is typically above empty box conditions. Once the controller’s operating range and engineering units are configured correctly, they can be applied to relay set points for pumps, valves, or alarm automation.

Critical control points:

The main control task is to ensure that the cooling tower is filled in time before the water is reduced due to evaporation. This avoids process interruptions due to lack of water. Typically, this is accomplished via a valve. The filling process should start at a low level and stop at a high level.

Set alarm point:

- A low level alarm or shutdown set point should be set below the open valve set point to ensure filling begins before the low level reaches this point.

- For safety reasons, it is recommended to use an independent high level alarm or safety shutdown system in addition to the main control system.

- Likewise, for process protection it is recommended to use an independent low level alarm or safety shutdown system.

The PLC, SCADA, DSC or independent level controllers mentioned above need to be provided by professional suppliers. If you do not have these systems and want to achieve control, you can use the level recorders provided by Sino-Inst.

The T710 series ultrathin paperless recorder adopts the new large-scale integrated circuits to realize the reliable protection and robust anti-jamming for input, output, power supply and signals. The recorder can achieve eight-channel universal signal input (the configurable and optional inputs include standard voltage, standard current, thermocouple, thermal resistance and millivolt), four-channel alarm output and one feed output. It has the RS485 communication port, Ethernet port, micro-printer port, USB device port and SD card socket. The recorder enjoys a powerful display function, which can achieve real-time graphic display, historical graphic recalling, bar graph display and alarm status display.

| Alarm output: Output through normally open contacts of the relay;Contact capacity: 1A/250VAC and1A/24VDC (resistive load)(! Note: If the load excesses to the relay contact capacity, do not load directly.) |

| Feed output: DC24V±10%, load current: ≤100mA |

| Communication output: RS485 communication port:Baud rates range: 2400 – 19200bps (settable);The standard MODBUS RTU communication protocol is adopted. The communication distances of the RS485 port is 1 km.Ethernet communication port:Communication speed: 10/100M, auto. |

More Level Measurement Solutions

Case: High Temperature Radar Level Transmitter for Melted Salt-Solar Photovoltaic Power Station

Ultrasonic Level Transmitter Installation Guide

Liquid Level Sensor Probes Types and How to Select

What Is the Ultrasonic CO2 Level Indicator? CO2 Bottle Level Measuring Device

Radar Level Gauge – Everything You Should Know and Selection List

Innovative Methods for Fluid Level Measurement

Grain Bin Level Indicators: The Missing Piece in Your Grain Storage Solution

The control of cooling tower water level is the core to ensure stable and efficient operation of equipment. With Cooling Tower Level precise measurement, alarms and controls, we can maximize cooling tower efficiency and safety. Hopefully the above guidance will provide you with valuable assistance in ensuring your cooling tower system is operating at its best.

At Sino-Inst, we don’t just limit ourselves to level measurements. Dive deeper into our vast array of instruments tailored for condensate flow measurement, pressure measurement, and temperature measurement. With years of industry experience under our belt, we pride ourselves on being seasoned manufacturers and suppliers who understand the nuances of these instruments. Our expertise is our testament.

Here at Sino-Inst, we cater to custom requirements, ensuring you get the perfect fit for your needs. Reach out to us today and let’s engineer success together.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.