Coriolis Flow Meter Density Measurement is also an important industrial application. Coriolis flow meters are pivotal tools in the industrial world. Simply put, they measure how much liquid or gas flows through them. But they have a special feature: they can also tell us the density of that liquid or gas.

Coriolis flow meters provide a two-in-one solution, giving industries a clearer and more complete picture of their operations. With accurate flow and density data, businesses can ensure they’re operating at peak efficiency and producing the best possible products.

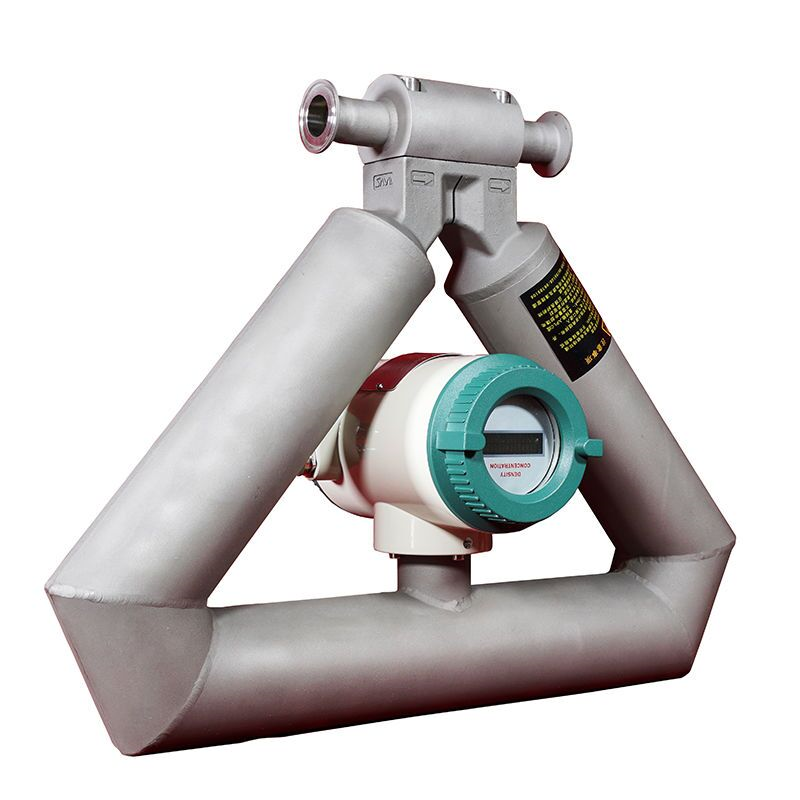

Featured Coriolis Flow Meters and Density Meters

How Coriolis Flow Meters Achieve Density Measurement

Coriolis flow meters stand as a benchmark in industrial precision. Here’s how these powerful tools get the job done when it comes to measuring density.

Inside the Coriolis flow meter, there are specially designed tubes through which the fluid or gas travels. Under normal conditions, these tubes remain steady. However, when the substance starts flowing, an external force causes the tubes to oscillate or move in a specific manner. This movement is influenced by the Coriolis effect, a fundamental principle in physics.

The oscillation of these tubes is affected by the density of the fluid passing through. For instance, a thicker fluid, like a heavy oil, will cause the tubes to move differently compared to a lighter fluid, like water.

To capture these oscillations, the meter is equipped with advanced sensors. These sensors detect even the slightest change in the tube’s movement, providing a direct measure of the fluid’s density. The data from the sensors is then processed, giving industries a clear and precise reading of not just the flow rate, but also the fluid’s density.

In industrial applications, this level of precision is essential. Whether refining oil, processing chemicals, or managing water treatment facilities, understanding fluid density ensures optimal process control, efficient operations, and high-quality outputs.

In essence, through the combination of ingenious design and the principles of physics, Coriolis flow meters deliver unparalleled accuracy in density measurement, solidifying their place in modern industrial setups.

Key Benefits of Using Coriolis Flow Meter Density Measurement

In the vast landscape of industrial tools, Coriolis flow meters have carved a unique space. Their capacity to measure both flow rate and density brings with it a slew of benefits. Let’s delve into the most prominent advantages:

- Accuracy: At the forefront is precision. Coriolis flow meters are renowned for their ability to give spot-on readings. This ensures industries can trust the data they receive, leading to better decision-making and product quality.

- Versatility: These meters can handle a broad range of fluids, be it liquids or gases. Whether you’re dealing with water, chemicals, or even liquefied gases, this tool can measure it all.

- Efficiency: Time is of the essence in industries. The dual function of measuring flow and density simultaneously means tasks are done faster, streamlining processes and boosting productivity.

- Durability: Built for rugged industrial environments, these meters are robust. They can withstand high pressures, temperatures, and even corrosive materials, ensuring longevity and reduced maintenance costs.

- Cost Savings: While the initial investment might be higher compared to other meters, the long-term savings are considerable. With reduced maintenance, improved efficiency, and minimized errors, industries stand to save significantly.

- Enhanced Process Control: Real-time and accurate data mean industries can make immediate adjustments if needed. This ensures optimal operation, reducing wastage and ensuring the consistent quality of end products.

- Safety: Given their precision, these meters can quickly detect irregularities or potential issues, enabling timely interventions. This proactive approach enhances safety in industries, especially those dealing with volatile substances.

In conclusion, Coriolis flow meters are not just tools; they’re invaluable assets. They simplify complex processes, ensure unparalleled accuracy, and provide industries with the confidence to operate at their best. Investing in such technology promises a future of efficiency, quality, and innovation.

More Detection and Analysis Sloutions

- Industrial Slurry Density Measurement-Featured Slurry Density Meters

- Density 101: What Is the Unit of Measurement for Density

- Industrial Applications of Various Density Meters

- What Is Density Meter? and Types

- Dew Point Monitor for the Fruit and Vegetable Industry

- What Is a Dew Point Monitor and How to Choose One?

- The Role of Dew Point Meter for Compressed Air Systems

- More than Just Compressed Air! What Gases Can the Dew Point Meter Detect?

- Top 1 Guide to Dew Point Measurement

- What Is Zirconia Oxygen Sensor?

In the intricate realm of industrial measurement, the importance of accuracy and efficiency cannot be overstated. The Coriolis flow meter, with its unparalleled precision in measuring both flow rate and density, stands as a testament to technological advancement. Choosing the right instrument can significantly impact productivity, safety, and overall output quality.

At Sino-Inst, we understand the critical role these devices play. With a rich history of expertise and dedication, we’ve established ourselves as seasoned manufacturers and suppliers in this domain. Our commitment is to provide not just products, but reliable solutions tailored to your specific needs.

Trust in Sino-Inst – your partner in precision and performance. Reach out to us today and let’s craft the perfect solution together.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.