Diesel Fuel flow meters are digital flow meters for liquid fuel consumption measurement.

Most widely used types are mechanical and digital inline fuel meters. Differential flow sensors are avilable. Like: the turbine, positive displacement (oval gear), Coriolis, and differential pressure flow meters.

Sino-Inst offers a variety of fuel flow meters for most fuels. Including diesel, bio-diesel, kerosene, gasonline, oil, heating oil, grease and certain chemicals.Sino-Instrument offers diesel fuel flow measurement solutions and free technical support. If you have any question for diesel fuel flow measurement, please contact us.

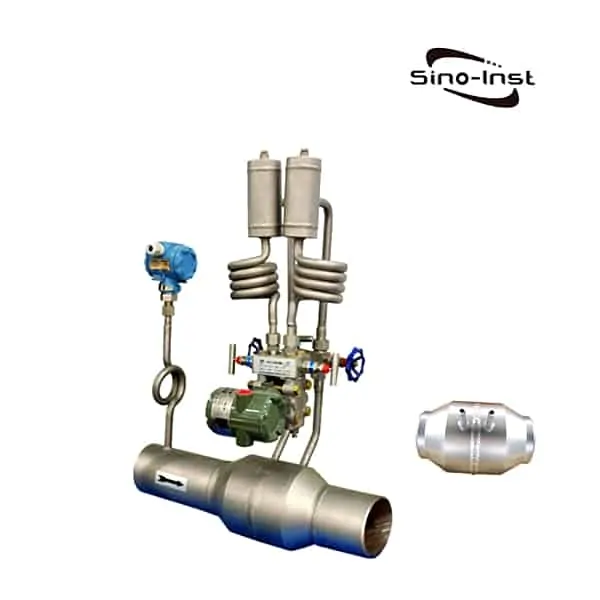

Featured Inline Diesel Fuel Flow Meters

Features of Diesel Fuel Flow Meters

Turbine flow meter for Diesel Fuel

- High performance ±1%R, ±0.5%R, high precision ±0.2%R;

- Good repeatability, short-term repeatability of 0.05% to 0.2%

- Output pulse frequency signal

A very high frequency signal (3~4kHz) can be obtained, and the signal resolution is strong; - The medium and large caliber can reach 1:20 and the small diameter is 1:10.

- Easy installation and maintenance, and large circulation capacity;

- Suitable for high pressure measurement

- Can be made into insert type for large diameter measurement

- Low pressure loss and low price

Mass flow meter for Diesel Fuel

- Double-U or double-C flow tube ensures high accuracy and customer’s requirement.

- Provides integrated mass flow, volum flow, density, temperature measurement and relative calculated parameter.

- Easy on Installation, do not need rectifier and filter parts.

- Fixed parts, maintenace free. High stability, no need for frequent disassembly calibration.

- Allow low-range operation, reducing pressure loss and energy consumption waste.

- Integrated installation, low installation costs.

- Extremely high accuray and long-term stability, could be used for business transaction.

- Ultra-wide measure range, could measure gas accurately (gas mass flow meter).

- Transmitter can be exchanged, and will not be influenced by area temperature.

Annubar Flow Meter for Diesel Fuel

- Honeycomb hexagonal stable structure,increasing the range ratio.

- Suitable for square or rectangular pipes.

- For the unavoidable clogging problem of similar products in measuring dirty media, achieve non-stop production maintenance.

- Average speed tube + three valve group + temperature pressure compensation + transmitter, form an integrated structure, easy to use.

- No flow coefficient drift, long-term stability.

- Exclusively provide intuitive resonance check to ensure long-term stable operation.

- Low pressure loss, low energy consumption, significant energy saving effect.

- Easy to install and save labor, low price and fast delivery (1 week)

Orifice Flow Meter for Diesel Fuel

- The Orifice meter is very cheap as compared to other types of flow meters.

- Less space is required to Install and hence ideal for space-constrained applications

- The operational response can be designed with perfection.

- Installation direction possibilities: Vertical / Horizontal / Inclined.

Venturi Flow Meter for Diesel Fuel

- Less head loss than an orifice or nozzle meter, due to the streamlined design

- Ideal for clear gas, liquid or steam applications

- Available in many materials and end arrangements

- Can be equipped with fittings to accept secondary instrumentation packages

You may like: Digital Flow Meters Guide| Liquid and Gas

Diesel Fuel Flow Meters Applications

Diesel, bio-diesel, kerosene, gasoline.

Petroleum, organic liquid, inorganic liquid.

Liquefied gas, natural gas, coal gas.

Oil, DEF, heating oil, grease and certain chemicals, low temperature fluid flow measurement.

Extended reading: More Inline Digital Diesel Fuel Flow Meters

Extended Reading: Petroleum Flow Meter

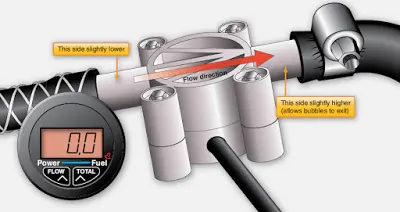

Flow Meters Pulse Output

The signal output by the flowmeter is generally a pulse signal or a 4-20mA current signal. Both types of signals output instantaneous flow (also used by relays to output cumulative signals. The principle is the same, and will not be repeated).

Our purpose is to PLC Calculate and display the instantaneous flow value and calculate the cumulative value. When the input signal is a pulse signal. When calculating the instantaneous flow rate, you must follow a strict time interval to ensure the accuracy of the instantaneous flow rate.

So, when calculating the instantaneous flow rate, This must be done using timed interrupts. Moreover, only one interrupt program can be run in a PLC system. No other interrupts are allowed (even low priority interrupts are not allowed to run).

Prevents interference with the accuracy of timed intervals. Calculating the instantaneous flow rate is to convert the accumulated pulse number of this time period into the accumulated flow rate. Divided by time is the instantaneous flow.

For the 4-20mA input, the instantaneous flow rate can be directly obtained by simply converting according to its corresponding range. The cumulative flow is the cumulative flow accumulated in each time period is the cumulative flow.

Flow meters with a pulse output essentially use pulses per litre to measure the amount of fluid being dispensed. And then send a signal to an external piece of equipment to tell them this information.

A fuel pulse meter for example is often connected to a remote display or a fuel management system.

Our range of fuel pulse meters include models suitable for different fluids and are compatible with pumps with differing flow rates. Ensure that when selecting your meter, its flow range meets your pump’s flow capabilities.

Of course, in addition to measuring Diesel Fuel flow meters. Other flow meters can also output pulses or 4-20mA signals.

For example, if you need to measure the waste water flow of a 2-inch pipe, then you can refer to: Magnetic Flow Meters Guides.

How much is a 2 inch water flow meter? Let’s find out.

Fuel Flow Meters for Diesel Engine Fuel Consumption

For generators, boats, trains to hydraulic packs applications. Diesel engines are becoming increasingly popular.

Fuel consumption and efficiency are generally not monitored in Diesel Engines. And the unit’s performance has to be gauged from the manufacturer’s test figures and often never checked again.

With increases in fuel prices, the possibility of theft from remote installations along with many other factors. So the monitoring the fuel consumption of diesel engines has become increasingly important with the transport industries in particular taking a lot more interest in their vehicles fuel consumption.

This chart approximates the fuel consumption of a diesel generator. Based on the size of the generator and the load at which the generator is operating at. Please note that this table is intended to be used as an estimate of how much fuel a generator uses during operation. And is not an exact representation due to various factors that can increase or decrease the amount of fuel consumed.

Extended reading: Fuel Flow Meter for Boat-Selection & Application

Ddiesel engine fuel consumption chart

| Generator Size (kW) | 20 | 30 | 40 | 60 | 75 | 100 | 125 | 135 | 150 | 175 | 200 | 230 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 1000 | 1250 | 1500 | 1750 | 2000 | 2250 |

| 1/4 Load (gal/hr) | 0.6 | 1.3 | 1.6 | 1.8 | 2.4 | 2.6 | 3.1 | 3.3 | 3.6 | 4.1 | 4.7 | 5.3 | 5.7 | 6.8 | 7.9 | 8.9 | 11 | 13.2 | 16.3 | 21.6 | 26.9 | 32.2 | 37.5 | 42.8 | 48.1 |

| 1/2 Load (gal/hr) | 0.9 | 1.8 | 2.3 | 2.9 | 3.4 | 4.1 | 5 | 5.4 | 5.9 | 6.8 | 7.7 | 8.8 | 9.5 | 11.3 | 13.1 | 14.9 | 18.5 | 22 | 27.4 | 36.4 | 45.3 | 54.3 | 63.2 | 72.2 | 81.1 |

| 3/4 Load (gal/hr) | 1.3 | 2.4 | 3.2 | 3.8 | 4.6 | 5.8 | 7.1 | 7.6 | 8.4 | 9.7 | 11 | 12.5 | 13.6 | 16.1 | 18.7 | 21.3 | 26.4 | 31.5 | 39.3 | 52.1 | 65 | 77.8 | 90.7 | 103.5 | 116.4 |

| Full Load (gal/hr) | 1.6 | 2.9 | 4 | 4.8 | 6.1 | 7.4 | 9.1 | 9.8 | 10.9 | 12.7 | 14.4 | 16.6 | 18 | 21.5 | 25.1 | 28.6 | 35.7 | 42.8 | 53.4 | 71.1 | 88.8 | 106.5 | 124.2 | 141.9 | 159.6 |

Learn more about Diesel fuel tank level gauges & Indicators

Fuel flow meter aircraft

A fuel flowmeter for plane indicates an engine’s fuel use in real time. This can be useful to the pilot for ascertaining engine performance and for flight planning calculations.

The types of fuel flow meter used on an aircraft depends primarily on the powerplant being used and the associated fuel system. Not every plane or associated system uses the same kind of flow meter to get the job done.

In most cases, many flow meters perform tasks related to maintaining a single plane. Some of the more common flow meters in use include:

- Open Channel Flow Meters

- Mass Flow Meters

- Turbine Flow Meters

- Positive Displacement Flow Meters

- Variable Area Flow Meters

- Velocity Flow Meters

- A mass flow fuel flow indicating system used on turbine-engine aircraft uses the direct relationship between viscosity and mass to display fuel flow in pounds per hour

- A turbine flow transducer in this fuel flow sensor produces a current pulse signal from an opto-electronic pickup with a preamplifier

- A transducer and microprocessor for control functions are located in the base of this turbine fuel flow sensor. The gauge is menu driven with numerous display options

https://www.aircraftsystemstech.com/2017/06/fuel-system-indicators.html

Every flow meter must be properly maintained and calibrated. All flow meters become inaccurate over time through regular use. Regular re-calibrations and general standards to ensure proper operation.

Flow meters designed for the aviation industry are made of the highest quality materials and to specific industry standards. That way, everyone working in the industry and flying the skies can be in the safest environment possible at all times.

Extended Reading: Fuel Flow Meters for Diesel-Marine fuel-Industrial oil

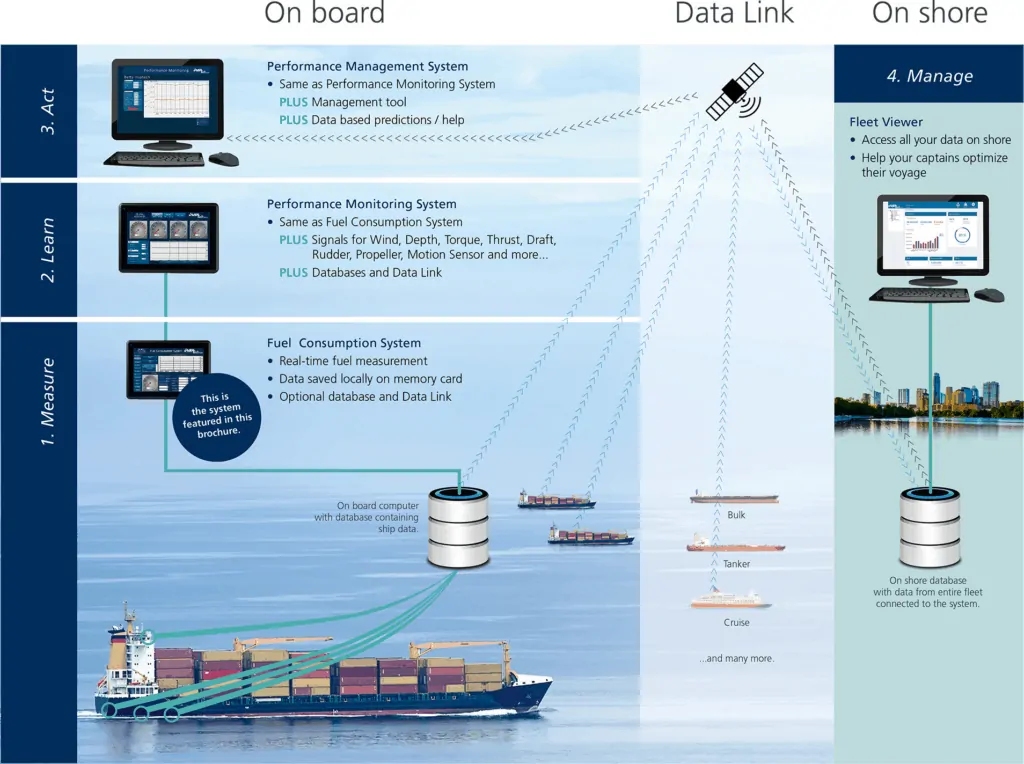

Marine diesel fuel flow meter

https://www.insatechmarine.com/products/performance/fuel-consumption-system

- How much fuel is consumed onboard a ship, is directly related to the performance. The better the performance, the lower the fuel consumption during operation. In this equation, accuracy is not negligible.

- An offset of 1% in measurement on a vessel operating 200 days a year consuming an average of 100 tons a day equals an offset of 200 tons a year. Depending on the price of HFO or MGO used, this misread has the potential to range up to USD 100,000.

- The Coriolis Mass Flow Meters used in our Fuel Consumption System has an accuracy better than 0,2% of nominal flow directly measured in mass. Whereas most volumetric flow meters are in the range 0,5% to 2,0%. And they rely on volumetric conversion which depends on the temperature to calculate a mass flow.

- By installing one or more mass flow meters (depending on engine supply line layout and desired insight) fuel consumption can be monitored closely in real-time.

- The main principle is to measure the flow of fuel before and after the engine and/or generators. When you compare the consumption data with measurements of actual speed and position (based on speed log and GPS signals). You are able to directly measure the fuel efficiency.

- If you require more detailed readings, for example, one set of meters per consumer or one set for the ship’s entire consumption. Additional flow meters can be installed.

Read more about: Large-diameter Oval Gear-Marine Fuel Flow Meter

More Technical Supprots

Fuel Flow Meters for Diesel-Marine fuel-Industrial oil

What is a fuel flow meter? Fuel flow meter is an instrument that can monitor fuel flow. Industrail Fuel is an important energy source. For example, diesel, marine fuel, gasoline, etc.

Industrail Fuel is an important energy source for production and manufacturing. For example, diesel, marine fuel, gasoline, etc. It is very necessary to accurately measure industrial fuel. Commonly used industrial fuel flow meters, such as turbine flow meters, gear flow meters, mass flow meters, ultrasonic flow meters, etc.

Related Blogs

Sino-Instrument offers Popular fuel flow sensor of Good Quality and at Affordable Prices

If you are interested in fuel flow sensor, Sino-Instrument has over 100 flow meters related, so you can compare and shop! Try finding the one that is right for you by choosing the price range, applications, or specifications that meet your needs. You will find a high quality fuel flow sensor at an affordable price from Sino-Instrument.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.