Diesel fuel tank level gauges for industrial oil storage tanks are very important, for level monitoring. Can be divided into mechanical and electronic.

Diesel tank gauges are installed onto industrial diesel tanks. It is used to directly or indirectly measure the liquid level of oil and other media. for the purpose of monitoring fuel consumption or reserve. They are often combined with a diesel tank alarm. This can effectively detect and control diesel fuel consumption.

Sino-Inst offers a variety of Diesel fuel tank level gauges for industrial level control. If you have any questions, please contact our sales engineers.

Featured Diesel fuel tank level gauges for Sale

Read more about 7 Level Senors for Tank Level Measurement

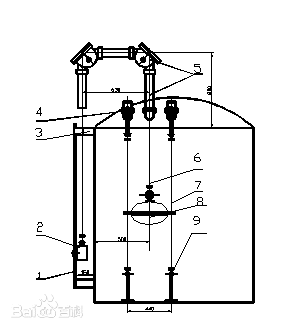

Mechanical diesel fuel tank level gauge

Mechanical level gauges are currently used in petroleum, chemical, electric power, metallurgy, light industry, textile, national defense, and other industries. They are used to directly or indirectly measure the liquid level position of atmospheric oil and other media.

Float level gauges, magnetic flap level gauges, etc. are all based on this measuring principle.

- Simple structure, intuitive reading and convenient installation.

- The float is made of stainless steel with good anti-corrosion performance.

- The float has a large cross-section and a certain cylinder height, so it is highly sensitive and has a wide application range for liquid specific gravity.

- The guide wheel box is made of cast aluminum, and the friction coefficient of the inner guide wheel is small, which improves the measurement accuracy.

Extended reading: Magnetostrictive Hydraulic Cylinder Position Sensor

Electronic Fuel Tank Level Gauge

Generally speaking, the power supply is basically electronic. Float, capacitive, radar, ultrasonic, remote magnetic flap including liquid level transmitter and so on.

It is simple to distinguish them. No matter it is the internal power supply or an external power supply. Whether it is 24V or 220V. In short, the electronic type must be powered to work.

Different from the mechanical type, the working principle of the electronic level gauge is varied.

For example, the radar level gauge uses microwaves, the magnetostrictive level gauge uses current pulses, the static pressure type uses the pressure generated at the bottom of the measured medium, and the ultrasonic level gauge uses ultrasound to measure the liquid level.

High precision, easy to install, adapt to a variety of installation environments. These are the characteristics of electronic liquid level display instruments. Compared with the mechanical type, their technical level is higher. But at the same time, the price is much higher than that of the mechanical type.

Extended reading: Industrial Tank level indicators and Tank Level Gauges

Fuel tank level monitor

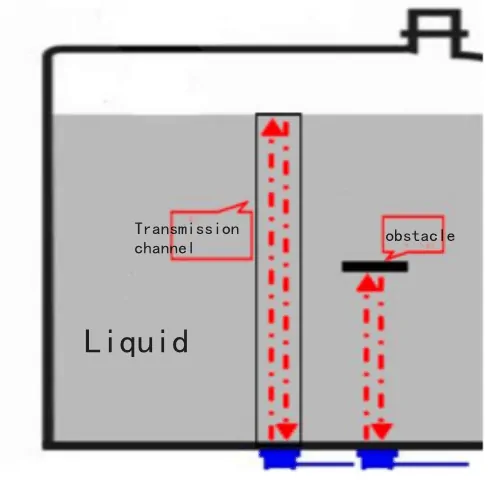

Ultrasonic externally attached oil level sensor uses the principle of ultrasonic echo ranging. The sensor is installed outside the bottom of the fuel tank and sends out an ultrasonic signal from the bottom, which is reflected by the oil surface, and then calculates the height of the liquid level according to time and speed.

At the same time, combined with digital signal processing technology, it overcomes the influence of the container wall and realizes high-precision non-contact measurement of the liquid level in the container, which can meet the requirements of industrial applications in terms of application.

Extended reading: Radar Oil Tank Level Sensor

Extended reading: What is a capacitive liquid level sensor?

External fuel tank level sensor

The oil level sensor is very important for monitoring the level of the oil tank/fuel tank. Ultrasonic Oil Level Sensor is mainly used for monitoring the level of truck oil tank. Oil level displays and transmit.

Ultrasonic oil level sensor uses the principle of ultrasonic detection to detect the fuel level of the fuel tank. The fuel volume data is transmitted to the background monitoring system to achieve real-time monitoring of vehicle fuel consumption. Ultrasonic oil level sensor is mainly used in the field of Internet of Vehicles to monitor the change of fuel level in the fuel tank in real-time to achieve fuel level detection. It can be used to prevent fuel stealing, optimize operating costs, optimize driver driving behavior, and assist statistical decision-making. At the same time, this product can also be used in chemical, water conservancy, storage tanks, and other fields that require level detection.

Read more: Ultrasonic Oil Level Sensor-External Paste-Truck Fuel Tank

Diesel fuel tank level monitoring system

There are actually two types of Diesel fuel tank level monitoring systems. One type is large industrial diesel storage tanks; the other type is small diesel tanks, such as truck fleets.

Oil tank liquid level monitoring/oil storage tank liquid level online monitoring system

Oil storage tanks are important equipment for oil extraction and refining companies to store oil. Accurate measurement of oil tank level and temperature is of great significance to the company’s inventory and safety management.

Oil tank level monitoring (on-line monitoring system for oil tank level and temperature) has changed the traditional methods of manual inspection and analysis. Realize the real-time dynamic monitoring of oil. Provide accurate data basis for production operation and management decision-making. Greatly avoid the occurrence of safety accidents.

If you need to measure high temperature and high pressure (-0.1MPa-32MPa) oil storage tanks, then learn about New Choice for Heating Oil Tank Level Sensor.

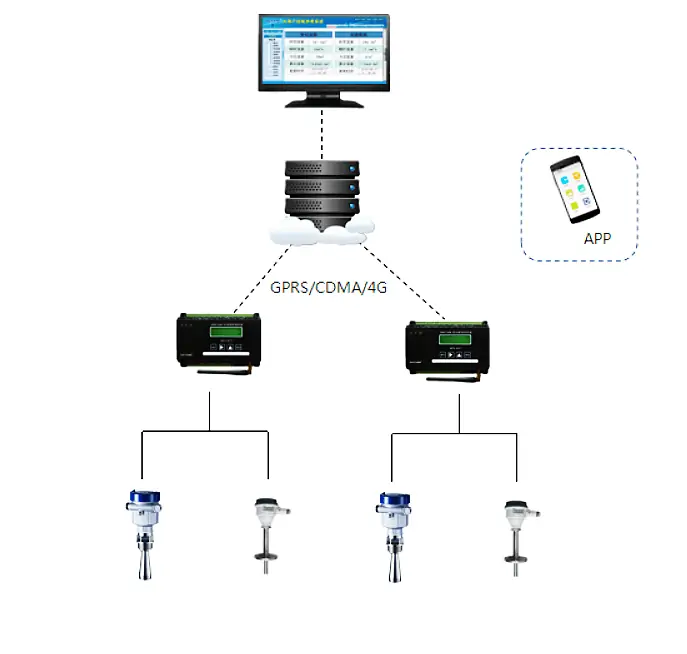

The oil tank level monitoring system uses a collection and communication integrated machine that integrates data collection and wireless transmission functions as the core equipment of the monitoring site. Automatically collect 4-20mA or RS485, RS232 output signals of level gauges and temperature transmitters and transmit them to the monitoring center in real-time via GPRS/CDMA/4G network.

The monitoring center receives monitoring data sent back from each site through monitoring software. And the liquid level and temperature information of each oil storage tank can be checked at any time on the software interface. And once the liquid level and temperature data of a certain oil tank exceed the upper or lower limit. The system will automatically alarm.

This system has played an important role in ensuring the safety of oil storage tanks and oil.

Extended Reading: Low Cost Float Level Sensor for Tank Liquid Volume Monitoring

Extended reading: ultrasonic level sensor price

Automobile fuel monitoring system

Using the fuel monitoring system, you can know:

- Where, when, how much gas was added, and how much did it cost to refuel?

- Where, when, how much oil was stolen, and how much oil was stolen?

- Where do you drive, how many kilometers, and how much gas did you use?

- Where is idling, how long is idling, and how much fuel is consumed?

The way to realize the oil quantity monitoring system:

- Real-time oil level consumption and abnormal oil level change alarm

- Refueling or abnormal consumption query

- Oil level curve analysis report

Extended Reading: Guide and Selection for Diesel Fuel Flow Meters

Frequently asked questions

Still have questions?

If you cannot find an answer to your question in our FAQ, you can always contact us

and we will be with you shortly.

You may like:

Sino-Inst offers over 10 Diesel fuel tank level gauges & Indicators for level measurement. About 50% of these are float liquid level meters, 40% is the level switches.

A wide variety of Diesel fuel tank level gauges & Indicators options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Diesel fuel tank level gauges & Indicators instrumentation, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.