What are flow elements? Simply put, a flow element is a device used to measure the rate at which a fluid (like water or gas) moves through a pipeline. Imagine a highway, and the flow element is the toll booth that monitors how many cars pass through. Only instead of cars, flow elements deal with the movement of fluid.

Types of Flow Elements

Understanding flow elements can feel like an adventure, with each type having its own unique characteristics and applications. Let’s delve into nine different types of flow elements, each offering unique advantages and suited to various applications.

Pitot Tube

The Pitot Tube, named after the French engineer Henri Pitot, measures the velocity of fluid flow by comparing the fluid’s static pressure to its dynamic pressure. These devices are simple, cost-effective, and ideal for applications where minimizing pressure loss is crucial.

Annubar Flow Element

Annubar Flow Elements, also known as averaging pitot tubes, have a distinct multiport design. They provide an averaged differential pressure output that allows for a more accurate measurement of flow rates, particularly in larger pipes and ducts.

Target Flow Sensor

Target Flow Sensors work a little differently. A ‘target’ (essentially a disc) is placed in the fluid flow, and as the fluid hits this target, it creates a force. By measuring this force, we can calculate the flow rate. These sensors are robust and can measure flow in both directions, making them versatile options.

Venturi Tube

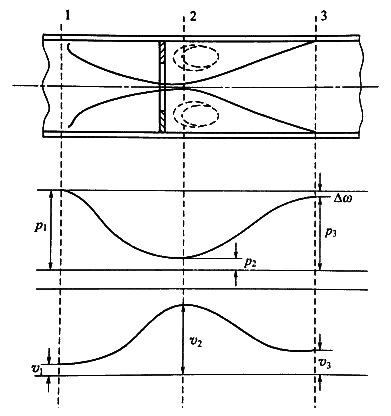

Venturi Tubes are designed for accuracy. They feature a distinct tube that first narrows, then widens. The fluid accelerates in the narrow section and decelerates in the wider section. This change in speed alters the pressure, which is used to calculate flow rate. If precision is your top priority, Venturi Tubes are worth considering.

Flow Nozzle

Flow Nozzles are the resilient heroes of the flow element world. Their durable design can handle high-speed flows and harsh conditions, like high temperatures in steam flows. If toughness is paramount, Flow Nozzles step up to the plate.

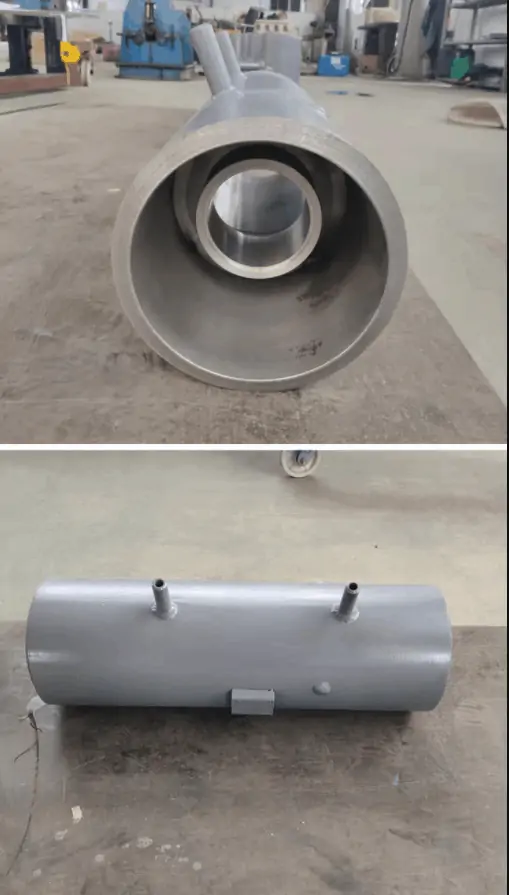

V Cone Flow Sensor

V Cone Flow Sensors are innovative devices that contain a cone inside the tube. As the fluid flows around the cone, it creates a differential pressure, which can be measured to calculate the flow rate. These sensors are known for their accuracy and are especially useful in difficult conditions, such as low-reynolds-number flows.

Segmental Wedge Flow Element

Segmental Wedge Flow Elements have a distinct, wedge-shaped restriction that generates a differential pressure, measuring the flow rate. They’re particularly effective for sludges, slurries, and other flows with a high solids content, which can pose challenges for other flow elements.

Elbow Flow Element

Elbow Flow Elements take advantage of a simple fact: fluid turning a corner creates a pressure drop. By placing a sensor on the inside and outside of the elbow, we can measure this pressure drop and calculate the flow rate. These devices are useful when space is limited.

Orifice Plate Throttle

Orifice Plate Throttles are one of the simplest and most widely used flow elements. They involve a flat plate with a hole in the middle, placed within the pipe. The pressure change as fluid flows through this hole gives us the flow rate. Simple, reliable, and cost-effective, these devices are a go-to in many industries.

Remember, choosing the right flow element depends on your specific needs, conditions, and the nature of your fluid. By understanding these different types, you’re well-equipped to make an informed decision. So, let’s continue to dive deeper into the world of flow elements!

Understanding Flow Rates and Measurements

Flow rate is crucial in a multitude of industries, including manufacturing, oil production, and water treatment, to name just a few. But how do we measure it? That’s where flow elements and the concept of differential pressure come in.

Flow elements are devices that create a change, or a difference, in pressure as the fluid passes through them – hence the term ‘differential pressure.’ Think of sticking your hand out of the window of a moving car. When you hold your hand flat, parallel to the ground, you feel a certain amount of pressure from the wind. Now, tilt your hand – the pressure changes. Flow elements create and measure this change in pressure, and from it, they can calculate the flow rate.

This is the basic principle behind differential pressure flow meters. These devices consist of a flow element, which creates a pressure drop, and a transducer, which measures this drop. The greater the flow, the larger the pressure drop, and vice versa.

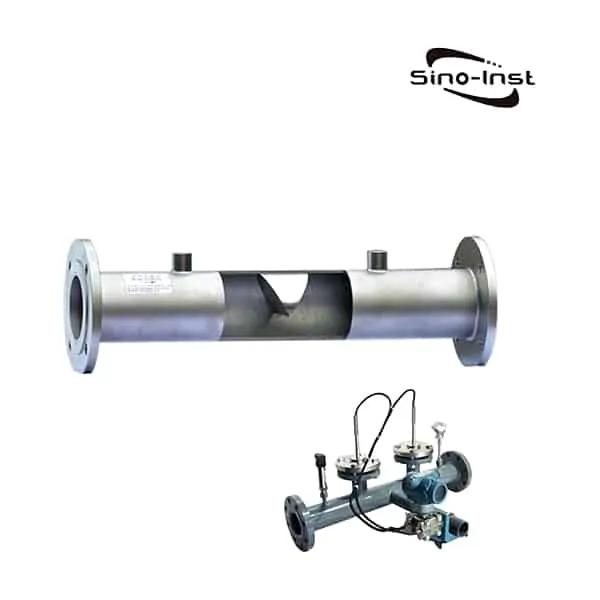

Top Flow Element Products

Applications of Flow Elements

Flow elements might be small, but they play a massive role in many industries worldwide. Let’s explore some of the applications where flow elements make a significant difference.

So, there you have it! From the oil in our cars to the air in our homes, the water in our cities to the drinks in our fridge, flow elements are hard at work. These small devices play a big role in making our world run smoothly.

FAQ

More Flow Measurement Solutions

What Is a Doppler Flow Meter?

Top Liquid Flow Meters in Industry

Exploring the Different Types of 1 Inch Flow Meters

Flow Meter Selection Guide 101: Find the Perfect Fit for Your Application

Top Industrial Heating Oil Flow Meters

The Different Types of Inline Oil Flow Meters

Remember that not all flow elements are created equal. Choosing the right type for your specific needs and conditions is vital. Whether it’s an Orifice Plate, a Venturi Tube, a Pitot Tube, or any other type, each offers unique advantages and capabilities.

At Sino-Inst, we bring a wealth of experience as manufacturers and suppliers in this domain. We offer a wide range of flow elements, and we stand ready to customize solutions that meet your unique requirements. Our mission is to help you navigate the complexities of flow measurements with ease and confidence.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.