Differential Pressure (DP) Flow Meters Technology –

Reliable Flow Solutions Across Many Applications

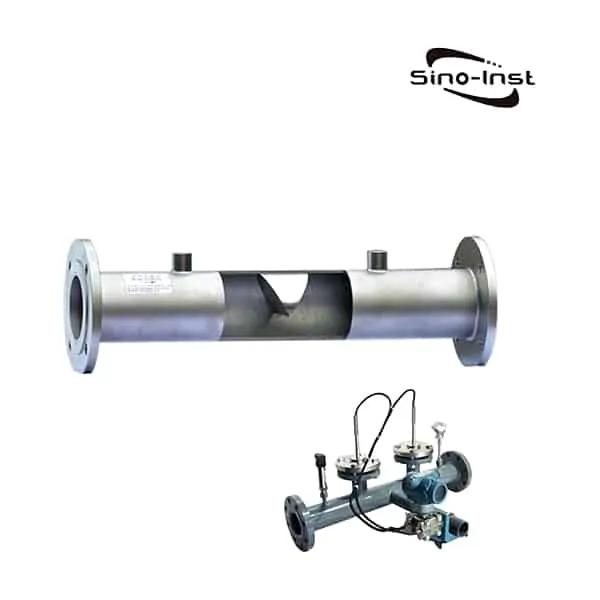

Differential Pressure Flow meters, also known as DP flow meters. Differential Pressure (DP) flow meters introduce a constriction in the pipe, that creates a pressure drop across the flow meter.

The calculation of fluid flow rate, by reading the pressure loss across a pipe restriction, is the most used flow measurement technique in industrial applications.

Differential pressure flow meters are suitable for water flow measurement, oil, steam or gas flow measurement.

According to different flow senor structures, we have:

- Orifice Plate Flowmeters;

- Venturi Flowmeters;

- Nozzle Flowmeters;

- Wedge Flowmeters;

- Annubar Flowmeter

And more.

What is a differential pressure flow meter?

You can take this as the definition of the differential pressure flow meter.

Differential pressure flow meters, also known as DP flowmeters, create a cross-sectional change in the flow tube, which causes the velocity of the flowing fluid to change.

A change in velocity occurs whenever there is a change in flow cross-section; ie, With a decrease in velocity, an increase in pressure occurs.

Differential pressure flow meters can be used as liquid flowmeters or gas flowmeters; however, a single flow meter may not be configured to measure both liquid and gas phases.

Differential pressure (also known as throttling) Flow meters, are based on the throttling principle of fluid flow. It is one of the most mature and most commonly used methods for measuring flow in production. It is usually composed of a throttling device, which capable of converting the measured flow into a differential pressure signal, and a differential pressure gauge, and a display instrument, capable of converting the differential pressure into a corresponding flow value.

In the unit combination meter, the differential pressure signal generated by the throttling device, is often converted to a corresponding standard signal (electrical or pneumatic), by a differential pressure transmitter for display, recording or control.

The differential pressure flow meter is composed of a primary device (detection member), and a secondary device (a differential pressure converter and a flow display instrument).

The differential pressure flow meter is usually classified in the form of a test piece, such as an orifice flowmeter, a venturi flowmeter, a constant velocity tube flowmeter, a pitot tube principle-Pitoba flowmeter, and so on.

The secondary device is a variety of mechanical, electronic, electromechanical integrated differential pressure gauges, differential pressure transmitters and flows display instruments.

It has developed into a large-scale instrument with a high degree of categorization (series, generalization, and standardization) and a wide variety of specifications.

It can measure flow parameters as well as other parameters (such as pressure, level, density, etc.).

You may like the pressure level transmitter.

How does a differential pressure flow meter work?

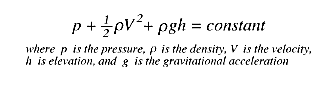

Differential pressure flow meters use Bernoulli’s equation, to measure the flow of fluid in a pipe.

Differential pressure flow meters introduce a constriction in the pipe, that creates a pressure drop across the flowmeter.

When the flow increases, more pressure drop is created. Impulse piping routes the upstream and downstream pressures of the flowmeter to the transmitter, that measures the differential pressure to determine the fluid flow.

This technology accounts for about 21% of the world market for flow meters.

Bernoulli’s equation states that the pressure drop across the constriction is proportional to the square of the flow rate. Using this relationship, 10 percent of full-scale flow produces only 1 percent of the full-scale differential pressure.

At 10 percent of full-scale flow, the differential pressure flowmeter accuracy is dependent upon the transmitter, being accurate over a 100:1 range of differential pressure.

Differential pressure transmitter accuracy is typically degraded, at low differential pressures in its range, so flowmeter accuracy can be similarly degraded.

Therefore, this non-linear relationship can have a detrimental effect on the accuracy, and turn down of differential pressure flow meters.

Remember that of interest is the accuracy of the flow measurement system — not the accuracy of the differential pressure transmitter.

Different geometries are used for different measurements, including the orifice plate, flow nozzle, laminar flow element, low-loss flow tube, segmental wedge, V-cone, and Venturi tube.

Read more about: Shop 101: Key Factors In Selecting A Pipe Flow Meter

Differential pressure flow meter formula:

where

- points 1 and 2 lie on a streamline,

- the fluid has constant density,

- the flow is steady,

- and there is no friction.

Although these restrictions sound severe, the Bernoulli equation is very useful, partly because it is very simple to use. And partly because it can give great insight into the balance between pressure, velocity, and elevation.

To learn more about DP Flow:

Extended reading: Smart Differential Pressure Transmitter

Advantages and disadvantages of differential pressure flow meter

The upside of this technology is low cost, multiple versions can be optimized for different fluids and goals, are approved for custody transfer (though it is being used less and less for this). It is a well-understood way to measure flow. And it can be paired up with temperature/pressure sensors, to provide mass flow for steam and other gasses.

Negatives are that rangeability is not good due to a non-linear differential pressure signal (laminar flow elements excepted), accuracy is not the best and can deteriorate with wear and clogging.

Advantages and disadvantages of throttling differential pressure flow meter (orifice flowmeter)

Advantages:

1) The standard orifice plate structure of the throttle piece is easy to copy, simple, firm, stable and reliable in performance, long in service life and low in price;

2) The throttling application range is extremely wide. All single-phase fluids, including liquid, gas, and steam, can be measured. Some mixed-phase flows, such as gas-solid, gas-liquid, liquid-solid, etc. can also be applied. General production processes and pipe diameters, The working condition (pressure, temperature) has products;

3) All accessories can be used by all manufacturers if it is an international standard and can be used without calibration.

Disadvantages:

1) The repeatability and accuracy of the measurement are medium levels;

2) The range is narrow because the meter signal and the flow rate are squared, the general range can only reach 3:1 ~ 5:1;

3) The requirements for on-site installation conditions are relatively high. If a long straight pipe section is required, it is difficult to meet;

4) The pressure piping is a weak link, which is prone to leakage, blockage, freezing and signal distortion;

5) The pressure loss is large.

Extended reading: Integral DP Flow Meter|Gas, liquid, steam|Compact structure

What is the relationship between flow and differential pressure?

Differential pressure use Bernoulli’s equation to measure the flow of fluid in a pipe.

Differential pressure flow meters introduce a constriction in the pipe, that creates a pressure drop across the flowmeter.

When the flow increases, more pressure drop is created.

y+P(x)y =Q(x)y^n (equation)

is called a Bernoulli differential equation where n is any real number.

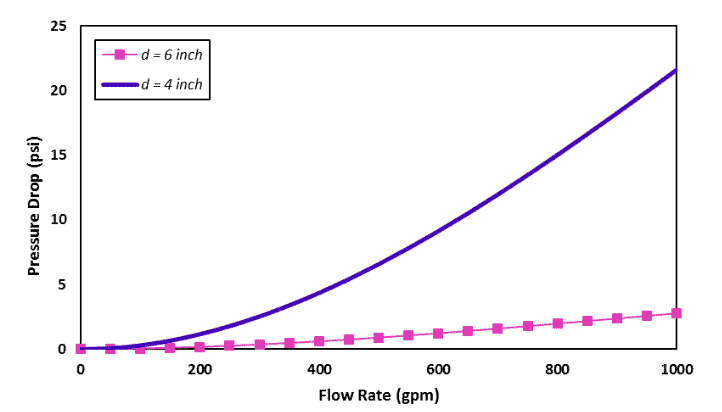

The graph below shows the resulting pressure drop for water at 60 F, over a range of flow rates for a 100-foot long pipe, for both 4 inches and 6-inch schedule 40 piping.

If you need, you can learn more about Flow Rate And Pressure Relationship.

How to Select a Flow Meter?

The basis of good flow meter selection is a clear understanding of the requirements of the particular application.

Therefore, time should be invested in fully evaluating the nature of the process fluid and of the overall installation.

- What is the fluid being measured by the flow meter(s) (air, water, etc…)?

- Do you require rate measurement and/or totalization from the flow meter?

- If the liquid is not water, what viscosity is the liquid?

- Is the fluid clean?

- Do you require a local display on the flow meter or do you need an electronic signal output?

- What are the minimum and maximum flow rate for the flow meter?

- What are the minimum and maximum process pressure?

- What are the minimum and maximum process temperature?

- Is the fluid chemically compatible with the flow meter wetted parts?

- If this is a process application, what is the size of the pipe?

Types of Differential Pressure Flowmeters

Featured DP Flow Meters for Sale

More Flow Measurement Solutions

Sino-Inst is a manufacturer of Differential Pressure Flow Meters. We supply more than 20 types of Differential Pressure Flow Meters. 30% are orifice plate flow meters. 30% are Annubar type flowmeters, and 40% are other differential pressure flowmeters,

Differential pressure flowmeter is a new type of transmitter integrating differential pressure transmitter, pressure transmitter, temperature transmitter, and flow totalizer. It can display working pressure, temperature, instantaneous and cumulative flow. It can also perform automatic temperature and pressure compensation for gas and steam, and realize the function of directly displaying the standard flow rate and mass flow rate on site. In the case of an external 24V power supply, it can also provide current, frequency, and 485 personnel transmission. And it can work for 2-3 years with one battery, and can be directly matched with differential pressure flowmeters.

There are many types of differential pressure flowmeters, such as orifice flowmeters, uniform velocity tube flowmeters, and Venturi flowmeters are based on flow sensing in pipelines. They calculate the flow according to the differential pressure generated by the flow detection in the pipeline. They have the advantages of firm structure, stable performance and long service life.

Sino-Inst has provided pressure measurement solutions to customers for many years. Our Differential Pressure Flow Meters, made in China. Widely exported to the United States, Britain, Germany, South Africa, Norway and other countries.

If you need Differential Pressure Flow Meterss, but have technical questions, please feel free to contact our sales engineers.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.