Digital Pressure Sensor is particularly suitable for use in computer control systems.

Digital pressure sensors measure the relative pressure of hydraulic and pneumatic systems. Pressure transmitters provide absolute or differential analog readings over a wide measurement range. SI-520 Digital Pressure Sensor passes high-reliability digital circuit 485 and precision temperature compensation. RS485 half-duplex working mode. This protocol complies with the MODBUS communication protocol. And uses a subset of RMOD methods in the MODBUS protocol. Digital Pressure Sensor adopts 304ss seal and welding, and has compact structure. Digital Pressure Sensor has good moisture resistance and excellent media compatibility.

Sino-Inst offers a variety of low pressure transducers for industrial pressure measurement. If you have any questions, please contact our sales engineers.

Such sensors are also commonly referred to as:RS485 pressure transmitter. MODBUS protocol transmitter. RS485 bus sensor. Digital signal pressure transmitter.

Measurement medium: weakly corrosive liquid; weakly corrosive gas.

Digital Pressure Sensor Features

- RS485 communication interface or HART communication protocol (optional)

- Using digital compensation and non-linear correction technology

- -10 ℃ ~ 70 ℃ digital wide temperature compensation

- Support networking application

- Digital display (optional)

- Special requirements can be customized to suit various occasions

Extended reading: Pressure indicator transmitters

Specifications of SI-520 Digital Pressure Sensor

| Amount | -0.1~0,0-1,6,10~100MPa | Ambient temperature | -20~85℃ |

| Supply voltage | 24VDC(10~36VDC) | Medium temperature | -20~85~105℃-500 |

| output signal | RS485 half duplex | Response time | <1ms |

| Protocol | MODBUS protocol | Electrical Interface | Stainless steel waterproof sealed terminal |

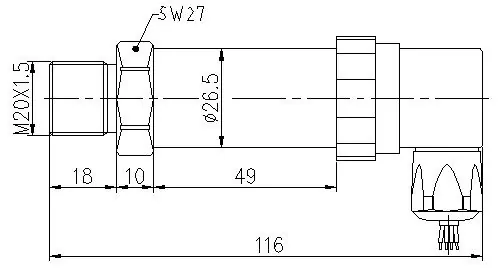

| Precision | 0.1%FS、 0.25%FS、0.5%FS | Threaded connection | M20 * 1.5 or according to customer requirements |

| Sampling rate: | 10 times / second. | Overload capacity | 150% |

| Communication speed | 9600bps,n,8,1 | Sealing level | IP65/68 |

| Communication speed | 9600bps,n,8,1 | Stability: | ≤ ± 0.15% FS / year |

| Serial port settings | No parity, 8-bit data, 1 stop bit. | ||

| Serial baud rate | 200,240,048,009,600,000,000,000,000,000,000,000 | ||

| Vibration effect | ≤ ± 0.15% FS / year (mechanical vibration frequency: 20Hz ~ 1000Hz) |

Extended reading: High Pressure Flow Meters for Liquids-Steam-Gas

SI-520 Digital Pressure Sensor Dimensions

Digital Pressure Sensor Applicaitons

- Various liquids, gases, or vapors compatible with 304, 316L stainless steel

- Static & dynamic pressure measurement

- Vacuum measurement/control

- Barometric pressure measurement

- Fluid level measurement

- Gas Flow

- Medical Instrumentation

- HVAC

You may like: Capacitive pressure transducer [What is & How does it work]

What does 485 communication (modbus protocol) mean in a pressure transmitter?

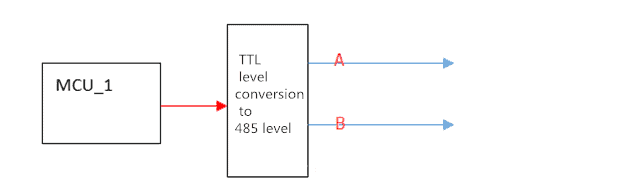

The pressure transmitter has a common 4-20mA output and has Hart protocol. There is also 485 communication which is the modbus protocol. Today we will talk about what is 485 communication.

MCU pin outputs TTL level. TTL level means when the MCU pin outputs 0 level. In general, the voltage is 0V. When the MCU pin outputs 1 level, the voltage is 5V. Because the TTL level is generated by a signal line and a ground line. The interference signal on the signal line will be transmitted to the receiving end with the effective signal, so that the effective signal is interfered. 485 communication actually converts the TTL level from the MCU through a converter chip in the hardware layer.

485 communication features:

- RS-485 electrical characteristics:

Logic “1” is represented by the voltage difference between the two lines being + (2-6) V. Logic “0” is represented by the voltage difference between the two lines being-(2-6) V. The interface signal level is lower than that of RS-232-C, so it is not easy to damage the chip of the interface circuit. And this level is compatible with TTL level, which can be easily connected to TTL circuits. - The maximum data transmission rate of RS-485 is 10Mbps.

- The RS-485 interface is strong, which means it has good anti-noise interference.

- The standard value of the maximum transmission distance of the RS-485 interface is 4000 feet, in fact it can reach 3000 meters (theoretical data, in actual operation, the limit distance is only about 1200 meters). In addition, the RS-232-C interface allows only one transceiver to be connected on the bus, that is, a single station capability. The RS-485 interface allows up to 128 transceivers on the bus. That is to say, it has multi-station capability, so that users can easily set up a device network using a single RS-485 interface.

RS485 disadvantages:

RS485 bus is a conventional communication bus. It cannot do automatic arbitration of the bus. That is, data cannot be sent simultaneously to avoid bus contention. Therefore, the communication efficiency of the entire system is necessarily low, and the amount of data redundancy is large. RS485 bus is not suitable for application places with high speed requirements. At the same time, because there is usually only one host on the RS485 bus, this bus method is a typical centralized-decentralized control system. Once the host fails, the communication of the entire system is limited to a paralyzed state. Therefore, it is an important measure to do online backup of the host.

Extended Reading: Resistive Pressure Transducer

More Featured Digital Pressure Transmitters

Technical Support

Frequently

Asked

Questions

Extended Reading: MEMS Pressure Sensors

Sino-Inst offers over 20 Digital Pressure Sensors. A wide variety of Digital Pressure Sensors options are available to you. Such as free samples, paid samples. Sino-Inst is a globally recognized manufacturer of Digital Pressure Sensors, located in China.

Sino-Inst sells through a mature distribution network that reaches all 30 countries worldwide. Digital Pressure Sensors products are most popular in Europe, Southeast Asia, and Mid East. You can ensure product safety by selecting from certified suppliers. With ISO9001, ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.