What is a float flow meter?

The float flow meter is also called a rotameter. The float flow meter is a volumetric flow meter in which a float rises and falls in a vertical tapered tube as the flow changes, changing the flow area between them. It is often called Variable Area Flowmeter or Area Flowmeter in the United States and Japan. The float flow meter can be used to measure the flow of liquid, gas, and steam. It is especially suitable for medium flow measurement under low flow rates and small flow conditions.

How does a float flow meter work?

Float Flow Meter is also called rotor flow meter. It is mainly used for small and medium caliber flow measurement. It can measure liquid, gas, steam, etc. The product series have complete specifications and are widely used.

Extended reading: Gas Rotameter Tips

Float Flow Meter working principle

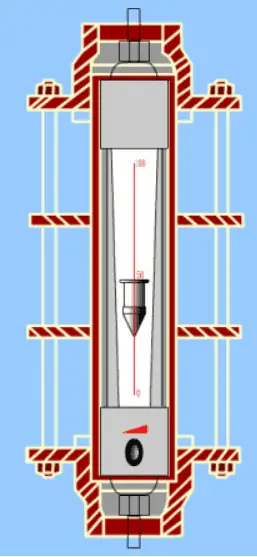

Float Flow Meter consists of two parts. One of the rotameter is a tapered tube that gradually expands from bottom to top. The other is a rotor that is placed in the tapered tube and can move freely up and down along the centerline of the tube.

When measuring the flow of fluid, the measured fluid flows in from the lower end of the tapered tube. The flow of fluid impacts the rotor and produces a force on it. The magnitude of this force varies with the flow rate.

When the flow is large enough, the generated force will lift the rotor and raise it.

Extended reading: Fluid flow meter types

At the same time, the measured fluid flows through the annular section between the rotor and the tapered tube wall. At this time, there are three forces acting on the rotor. The dynamic pressure of the fluid on the rotor, the buoyancy of the rotor in the fluid, and the gravity of the rotor itself.

When the flowmeter is installed vertically, the center of gravity of the rotor coincides with the axis of the tapered tube. The three forces acting on the rotor are all along the direction parallel to the axis of the tube.

When these three forces reach a balance, the rotor floats smoothly on a certain position in the cone tube.

For a given rotameter, the size and shape of the rotor have been determined. Therefore, its buoyancy in the fluid and its own gravity is known to be constant. Only the dynamic pressure of the fluid on the float changes with the flow rate of the incoming flow.

Therefore, when the flow rate of the incoming flow becomes larger or smaller, the rotor will move up or down. The flow cross-sectional area of the corresponding position also changes. Until the flow rate becomes the corresponding speed when the flow rate becomes balanced, the rotor is stable in the new position.

For a given rotameter, the position of the rotor in the cone tube is in one-to-one correspondence with the flow rate of the fluid flowing through the cone tube.

In order to prevent the rotor from touching the tube wall when moving up and down on the centerline of the tapered tube, two methods are usually used.

One is to install a guide mandrel in the center of the rotor to keep the rotor moving up and down on the centerline of the tapered tube.

The other is a chute on the edge of the rotor disc. When the fluid flows through the rotor from bottom to top, one side bypasses the rotor. At the same time, it passes through the chute to generate a reverse thrust. The rotor keeps rotating around the centerline. . It can keep the rotor from touching the pipe wall when working. The rotor material of the rotameter can be made of stainless steel, aluminum, bronze, etc.

Extended reading: Micro flow meters for low flow liquids

Types of Float Flow Meter-variable area flowmeter

Float type water flow meter

Rotameters can be used to measure the instantaneous flow of water. There are many flow meters for measuring water. Almost all flow meters that measure liquids can be used to measure water.

The original rotameter used to measure water is now used to measure the flow rate of gasoline. Is the reading correct?

Certainly not. Rotameter measuring liquid is most affected by liquid density and viscosity. It is recommended to find the manufacturer to tell them the parameters of your gasoline. It should be able to help you convert and tell you the true flow rate when the current scale is used to measure gasoline.

Rotameters measure different liquids. How to convert?

Rotameter display value correction. The fluid and state when the flowmeter is in use are generally different from the fluid and state when the flowmeter is scaled. Therefore, the value of the flow meter reading during use is not the real flow through the flow meter. The indicated value must be corrected according to the fluid and state in use. In order to get the correct flow.

The flow meter produced by Sino-Inst is calibrated with water for measuring liquid. The flowmeter for measuring gas is calibrated with air. The indicated value is scaled according to the volume flow rate of the standard state (water at 20°C; air at 20°C, 101.325KPa). Therefore, all corrections are based on the standard state index.

Extended reading: Beginner’s Guide: Variable area flow meter

More Featured Water Flow Meters:

Float air flow meter

Metal tube rotameter can be used to measure air. Because rotameter is a kind of variable area flow measuring instrument commonly used in industrial process automation control.

It has the characteristics of small size, large detection range, and convenient use.

It can be used to measure the flow of liquid, gas and steam. It is especially suitable for medium flow measurement with low flow rate and small flow, so there is no problem in measuring air.

However, it should be noted that the metal tube rotor flowmeter is only suitable for the flow measurement of small-diameter and low-velocity media within DN200.

More Featured air flow meters:

Frequently

Asked

Questions

Extended reading: Integral DP Flow Meter|Gas, liquid, steam|Compact structure

Sino-Inst offers over 30 Float Flow Meter products. About 50% of these are for liquids. 40% are for gas. At the best price.

A wide variety of Float Flow Meter options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Rotameter flow meters, located in China.

The top supplying country is China (Mainland), which supply 100% of the Float Flow Meter respectively.

Sino-Inst sells through a mature distribution network that reaches all 50 states and 30 countries worldwide. Float Flow Meter products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.