You may have heard of flow transmitters and flow meters. Are flow transmitter and flow meter the same? What is the difference and relationship between them before? Should you buy a flow meter or a flow transmitter? What kind of one to buy?

Let us discuss both flow meter and flow transmitters individually to you understand their concepts thoroughly.

What is a Flow Meter?

A flow meter is an instrument used to measure the flow of fluid in a pipeline or open channel. It measures the flow of fluids, liquids, or gases through a closed transmission system.

Flow meters are divided into differential pressure flow meters, rotor flow meters, throttling flow meters, slit flow meters, volumetric flow meters, electromagnetic flow meters, and ultrasonic flow meters. Classified by medium: liquid flow meter and gas flow meter.

Extended reading: Ultrasonic Flow Meters Types & Technical Guide

These different flow meters have different functional principles. For example, an orifice flowmeter calculates the fluid flow at the entrance cross-section of a narrow, restricted opening (called an orifice) and the exit cross-section of the orifice. On the other hand, a rotameter-type flow meter can measure the volume flow inside multiple tubes placed in different areas of the transfer tube.

The above is a general introduction to the flowmeter. simply put. We can think that the flow meter is composed of two parts: the sensor and the signal processor. This structure can be installed separately or as a whole.

So, the signal processing part here is the Flow Transmitter we are going to talk about next.

Extended reading: How does a rotameter work

What is a Flow Transmitter?

The flow transmitter is an important part of the flowmeter. It is a flow meter with an integrated circuit as its operating system. In the flow transmitter, the flow measurement activity is executed by the electronic circuit after receiving the command from the operator. Since flow transmitters have electronic circuits, these devices can be used to control and monitor fluid flow.

Read more about: Flow Meters With GPM Units

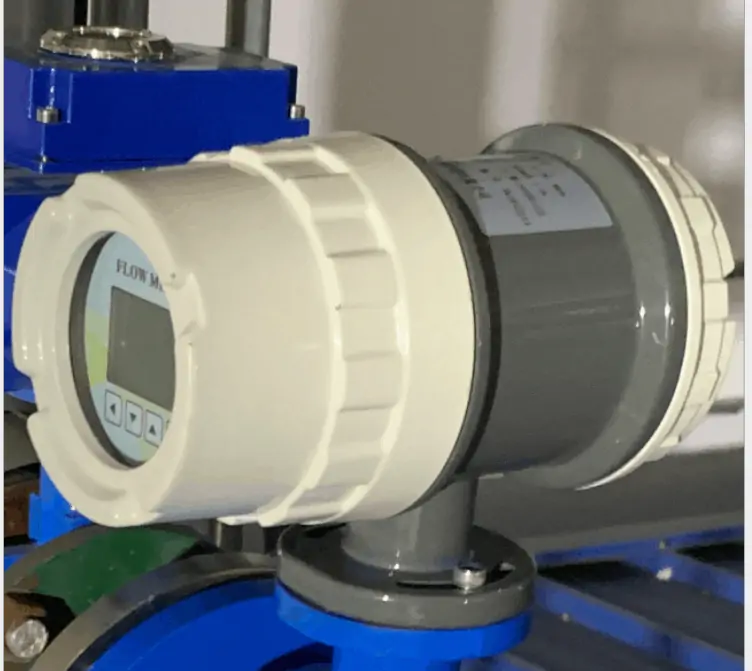

For example, the following picture group is the flow transmitter of our common electromagnetic flowmeter.

Guess you like: What is Reynolds number?

Working Principle of Flow Transmitters

A transmitter (transmitter) is a converter that converts the output signal of the sensor into a signal that can be recognized by the controller. It can also convert the non-electricity input from the sensor into an electrical signal and amplify the signal source for remote measurement and control.

There are many types of transmitters. The transmitters used in industrial control instruments mainly include temperature transmitters, pressure transmitters, flow transmitters, current transmitters, voltage transmitters, and so on. Among various types of instruments, transmitters have the most extensive and common applications.

Therefore, the flow transmitter converts the flow signal collected from the flow sensor into an electrical signal. The various electrical signals that have been converted are used to facilitate the reception and transmission of other instruments or control devices. Through the electronic circuit again. Unify the electrical signals from the sensors. Converted to standard 4-20MA.

For example:

The mass flow meter directly measures the mass value. The flow transmitter displays the volume value. This is the biggest difference! The output of the flow transmitter is 4~20MA, and the pressure can be directly displayed by connecting to the secondary meter.

Read more about What is a Flow Transmitter? on Instrumentation Forum.

Extended reading: rotameter applications

Differences between the Flow Meter and Flow Transmitter

The following are some important differences between flow transmitters and flow meters.

Extended Reading: Magnetic Battery Operated Flow Meter

Flow transmitter types

In fact, there is no strict classification of flow transmitters. The flow transmitter can be configured according to the customer’s functional requirements.

For example, customers need a digital display, 4-20mA output, integrated.

Or, the customer needs battery power. Digital display. No signal output.

Extended reading: Gas Rotameter Tips

Extended Reading: What Is Metal Tube Flow Meter? Rotameter Manufacturer

Flow transmitter calculation

The calibration methods and calibration requirements of flow transmitters with different functions are different. It is recommended that you check with the manufacturer before calibrating the flow transmitter. For example, the flow transmitter supplied by Sino-Inst has a key calibration function. Simple and easy to operate.

For another example, there are two calibration methods for common electromagnetic flowmeters. You may be reading: Magnetic flow meter calibration

Extended reading: Make Ultrasonic Open Channel Flow Meter Work for You

Applications of Flow Transmitters

Flow transmitters are commonly used in various industries, including but not limited to:

- Food & Beverage

- Industrial production process

- Environmental protection project: Water and wastewater

- Pulp & paper

- Pharmaceutical

- Biotechnology

- Oil & Gas

- Energy metering

- Metals and Mining

- Marine

- Power & Utilities

- Transportation

- Chemical

- Textile

- Building Automation

- Micro Electronics

- Biotechnology

- Marine meteorology, rivers and lakes

Extended reading: Food grade flow meters for Food & Beverage industry

Extended reading: High Pressure Rotameter for Liquids/gas-Upto 25 Mpa

Related blogs

Sino-Inst offers over 50 Flow Transmitters, with the Best Price.

A wide variety of Flow Transmitters options are available to you, such as free samples, paid samples.

About 13% of these are magnetic flow meters, 14% are Insertion Magnetic Flow Meter, 25% are Venturi flow meters, 13% are ultrasonic flow meters, and others are Liquid Turbine Flow Meters.

Sino-Inst is a Flow Transmitter supplier, located in China. Flow Transmitter s products are most popular in North America, Mid East, and Eastern Europe. The United States, and India, which export 99%, 1%, and 1% of Flow transmitters respectively.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.