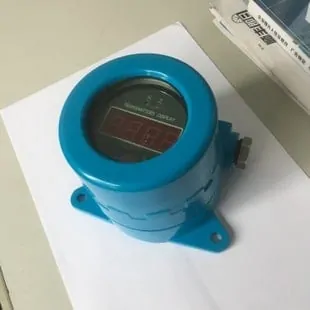

High temperature level sensor is based on FMCW Radar to measure high temperature liquid. Non-contact measurement. The temperature is as high as 240°C. IP67 protection. rs485 output.

High Temperature Level Sensor is also called high temperature molten salt level sensor. Use continuous frequency modulation wave radar to measure. SI-FMF15 FMCW Radar High Temperature Level Sensor is manufactured based on the principle of linear frequency adjustment-radar working. It can ensure the accurate and stable liquid level measurement of the radar in high temperature, high pressure, strong corrosion, strong dust and other environments. High temperature type 240℃, special customization can reach 1200℃.

Sino-Inst offers a variety of FMCW Radar High Temperature Level Sensors for industrial level measurement. If you have any questions, please contact our sales engineers.

Features of SI-FMF15 FMCW Radar High Temperature Level Sensor

- Measurement accuracy

The measurement accuracy of the terahertz frequency-modulated continuous wave radar level meter is ±1mm. Reliable and high-precision measurement. It really reduces the workload of field operators. - Launch angle

Radar wave emission angle <2°. Even in extremely complex installation environment, it can measure the material level stably and accurately. - Measuring range

The measurement range of the terahertz FM radar level meter is 0.08m-150m. It has a very small blind area and a large measurement range. It can meet most measurement occasions. - Penetration

The terahertz frequency-modulated continuous wave radar level gauge is extremely penetrating. According to the dielectric constant of the crystalline medium, it can penetrate the crystalline layer of up to 100mm. - High temperature conditions

The terahertz FM radar level meter has good penetration performance. For high temperature occasions, thermal insulation accessories such as ceramic or quartz glass can be added to the front end of the antenna. With the special environment learning function, it can measure high temperature liquids. - Strong corrosiveness

It has good penetration performance. For strong corrosion occasions, the front end of the antenna can be equipped with PTFE or PFA anti-corrosion sheath. And the maximum thickness of 30mm fluoroplastic can be added. It has good pressure resistance while anti-corrosion. - Foam products

It has good penetration performance. Therefore, it can penetrate the foam up to 1000mm for liquid level measurement. The terahertz frequency modulation radar level gauge can also measure the foam itself. - Sensitivity

It has three adjustable sensitivity. When high sensitivity is selected, the radar response time is less than 1S.

Specifications of SI-FMF15 FMCW Radar High Temperature Level Sensor

| Measuring medium: | Liquid |

| Measuring range: | 0.1m~120m |

| Process connection: | Flange≥DN80 |

| Process temperature: | Standard model -60~130℃; high temperature model -60~240℃; special customization -60~1200℃ |

| Process pressure: | -0.1~2.5 MPa |

| Accuracy: | ±2mm |

| Protection level: | IP67 |

| Frequency Range: | 123GHz |

| power supply: | Two-wire system (DC24V)/four-wire system (DC12V~24V)/four-wire system (AC220V) |

| Explosion-proof grade: | Exia ⅡC T6 Ga / Exd IIC T6 Gb |

| Housing: | Aluminum/plastic/stainless steel |

| Signal output: | Two-wire system 4…20mA/HART protocol Four-wire system 4…20mA/RS485 Mod bus |

Extended reading: What is Modbus Protocol?

SI-FMF15 FMCW Radar Level Sensor Applicable Medium

- Level measurement of solids (powders, granules, blocks);

- Level measurement of plastic particles with low dielectric constant;

- Liquid level measurement. Reactor liquid level. Large steam level. Foam product level. Crystalline product level. Ultra-high temperature product level. Ultra high pressure product level. Hygienic product level.

Extended reading: Dam water level measurement

Advantages of FM Radar Level Meter

FMCW radar level meter is suitable for various complex working conditions. It can also ensure measurement stability and accuracy in high temperature and high dust environments.

- Not affected by atmospheric precipitation;

- Ambient temperature from -60℃;

- from outside the storage tank;

- The inner antenna of the terahertz FM continuous wave radar level meter is heated and protected by a fluoroplastic lens

- The measurement beam is narrow. Easy installation and stable measurement;

- Level measurement accuracy;

- Not limited by the temperature in the container;

- Evaporation and dust do not affect the measurement;

- Boiling liquid level measurement;

- Corrosive liquid level measurement. No contact, no corrosion;

FMCW Radar Working Principle

In the early years, a non-contact frequency-modulated continuous wave radar level meter produced by a company in the United States used FMCW technology to perform more accurate level measurement for more complex occasions. This FMCW technology has caused a global sensation. It has made more researchers devote themselves to FMCW technology. FMCW here is frequency modulated continuous wave.

This FMCW radar technology uses a high frequency sweep signal typically 8.5 to 9.9 GHz. The radar signal is sent from one end of the antenna and is received by the receiver after time t. The frequency difference Δf between the transmitting and receiving is converted into the level of the measured medium by the Fourier transform method.

However, with the development of the times and the efforts of scientific researchers, the continuous waves of 26GHz, 28GHz, 80GHz and 120GHz have been derived from the FM continuous wave radar level gauge.

FM continuous wave radar level meter is a general-purpose instrument for measuring coal, cement, grain, alumina, limestone, chemical raw materials and other materials. It is widely used in cement, chemical, environmental protection, electric power, food and other industries.

The 120GHz radar level meter is especially suitable for high temperature, high pressure or high dust, and multi-stirring environments. It meets many measurement requirements that require a large range and high precision.

Terahertz FM CW radar level meter mainly uses triangular FM continuous wave. After the transmitted signal is scattered by the target, it is accepted by the antenna. The delay time τ=2R/c. Among them, R is the distance from the target to the antenna, and c is the propagation speed of the electromagnetic wave. .

When the detection target is stationary, the distance calculation formula is R=(cT/4B)×fb, where T is the period of the triangular wave, and B is the frequency modulation bandwidth.

From the formula R=(cT/4B)×fb, it can be obtained that the frequency fb of the beat frequency signal has a linear relationship with the distance R. Therefore, the key to the ranging system is to measure the frequency of the beat frequency signal.

Under certain conditions of bandwidth B and period T, the distance R can be calculated as long as the frequency fb is obtained. Therefore, the accuracy of frequency measurement directly affects the accuracy of distance measurement.

The difference frequency signal is usually sampled by A/D and then calculated by FFT to obtain the discrete spectrum of N points. Then fb is obtained by the peak frequency of the spectrum. Because the discrete spectrum will have a frequency domain sampling interval △f=fs/N.

In the formula, fs is the sampling frequency, and N is the number of sampling points.

The discrete spectrum sampling obtained by FFT generally cannot collect the peak point of signal frequency. That is, the integer multiple of the frequency interval does not coincide with the peak point, which causes the result of FFT analysis to be inconsistent with the actual frequency, resulting in frequency estimation error.

Extended Reading: Case: High Temperature Radar Level Transmitter for Melted Salt-Solar Photovoltaic Power Station

Level Measurement with FMCW Radar in Steam and High Temperature

When the measured medium is heated, or stored products with relevant physical and chemical properties (acids, alkalis, alcohols, etc.), there may be vapor accumulation in the upper space of the measured medium.

There are various vapors in the air in the space between the level gauge and the medium. It will not affect the accuracy and stability of the measurement. The FM continuous wave radar level gauge has this characteristic.

Level measurement by means of ultrasonic or optical (laser) means is a very unstable and inaccurate method. Because the speed of sound propagation depends on the composition of the atmosphere through which it passes. Direct optical visibility is required for measurement by laser means.

Level Sensors for High Temperature Applications

The high temperature and high pressure guided wave radar level sensor is specially designed for high temperature and high pressure occasions. The product is mainly used for liquid level measurement on various boiler drums. Has high safety and accuracy. The highest rated pressure reaches 40MPa. The highest rated temperature reaches 400℃. It is suitable for high and low pressure heaters, condensers and deaerators in thermal power plants. As well as for liquid level measurement under high temperature, high pressure, vacuum and other steam conditions.

Hydrostatic level transmitter is also called hydrostatic level gauge. The rod-type Hydrostatic level transmitter utilizes the linear relationship between liquid height, density, and pressure. The change of the level is converted into a linear 4-20mADC standard signal output. Suitable for tank level measurement. Flange or threaded installation. Can withstand high temperatures up to 450 ℃.

High Temperature Float Switch

Float level sensor can be widely used for continuous measurement of the liquid level (boundary level): High temperature. High pressure. Viscous, dirty media. Asphalt, wax-containing oil products and flammable, explosive, corrosive media.

Float level sensor (float switch) is one type continuous level sensor for industrial level measurement. Float level sensor has a magnetic float that rises and falls as liquid level changes. The movement of the float creates a magnetic field. Through the magnetic coupling effect, the internal resistance of the sensor changes linearly. The resistance change is converted into a standard current signal of 4 ~ 20mA by an intelligent converter. The percentage of the liquid level, 4 ~ 20mA current and liquid level value, can be displayed on site. Applications like: water tank, fuel tank, level measurement and level control. Vertical, horizontal, and side mounted, all can be satisfied.

Intelligent Solutions for High Temperature and Pressure

Related Blogs

Sino-Inst offers over 10 FMCW Radar High Temperature Level Sensors for level measurement. About 50% of these are Radar level meters, 40% is the tank level sensor.

A wide variety of FMCW Radar High Temperature Level Sensors options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of FMCW Radar High Temperature Level measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.