Gas turbine flow meter is a velocity flow meter that measures gas flow. For natural gas, nitrogen, and gas trade measurement.

The gas turbine flowmeter integrates temperature, pressure, flow sensors and intelligent flow totalizers. The gas turbine flowmeter has high accuracy and good repeatability, so it is suitable for trade measurement and industrial process detection. It is widely used in many kinds of gas in petroleum, chemical, metallurgy, aviation, scientific research and other sectors and industrial fields. Such as natural gas, city gas, propane, butane, air, nitrogen and other gases measurement.

Gas Turbine Flow Meter reference price: USD900-2500/pc

Sino-Inst offers a variety of Turbine flow meters for flow measurement. If you have any questions, please contact our sales engineers.

Industrial Propane Tank Level Indicators for Industrial Tank Level Measurement

Features of Gas Turbine Flow Meter

- High accuracy, good repeatability. Small pressure loss, good vibration resistance;

- Using high-quality bearings, low friction resistance, good sealing performance and long life;

- It integrates microprocessor, flow sensor, high-precision temperature and pressure sensor. Directly measure the flow, temperature and pressure of the measured gas. And automatically perform flow tracking compensation and compression factor correction operations;

- The meter has pulse signal and analog signal output. It can directly realize the centralized collection and real-time management of computer data through the RS485 communication interface or the GPRS system;

- Low power consumption, can be powered by internal battery or external power supply;

- With real-time data storage function, it can prevent data loss when the battery is replaced or the power is suddenly lost. In the case of power failure, internal data can be stored permanently;

- It can be used in conjunction with IC card prepayment system to facilitate trade settlement;

Specifications Of Gas Turbine Flow Meter

| Mediun : | No impurity, no corrosive gas, natural gas, etc. |

| Precision: | ±1.5%, ±1.0%, ±0.5%, |

| Repetition: | Better than 0.1% |

| Traffic Range: | 6.5~6500m³/h |

| Display content: | instantaneous working conditions, volume, standard volume, temperature, pressure, battery capacity, etc. |

| Calibre measurement: | DN50-DN300 |

| Connection mode: | Flange connection |

| Power supply: | Battery or external power supply operation |

| Output: | Pulse signal output, 4-20mA current output, RS485 communication GPRS remote communication |

| Inside nominal diameter DN (mm) | Made | Flow specification |

Startup flow rate (m3/h) |

Range of flow (m3/h) |

Pressure rating (Mpa) |

Sell material | Accuracy |

| 50(2”) | KLWQD-501 | G40 | ≤0.8 | 6.5~65 | 1.6 2.5 |

Aluminum alloy |

Accuracy 1.0: The allowable error is |

| KLWQD-502 | G65 | ≤0.9 | 10~100 | ||||

| KLWQD-503 | G100 | ≤1.7 | 16~160 | ||||

| 80(3”) | KLWQD-801 | G100 | ≤2.0 | 10~200 | 1.6 2.5 |

Aluminum alloy | |

| KLWQD-802 | G160 | ≤2.5 | 18~360 | ||||

| KLWQD-803 | G250 | ≤3.0 | 20~400 | ||||

| 100(4”) | KLWQD-1001 | G160 | ≤2.5 | 13~250 | 1.6 | Aluminum alloy | |

| KLWQD-1002 | G250 | ≤3.0 | 20~400 | ||||

| KLWQD-1003 | G400 | ≤4.5 | 32~650 | ||||

| 150(6”) | KLWQD-1501 | G400 | ≤7.5 | 32~650 | 1.6 | Aluminum alloy | |

| KLWQD-1502 | G650 | ≤8.5 | 50~1000 | ||||

| KLWQD-1503 | G1000 | ≤10.0 | 80~1600 | ||||

| 200(6”) | KLWQD-2001 | G650 | ≤12.0 | 50~1000 | 1.6 | carbon steel | Accuracy 1.5:The allowable error is Qmin~0.2Qmax:±3.0%; 0.2Qmax~Qmax;±1.5% |

| KLWQD-2002 | G1000 | ≤16.0 | 80~1600 | ||||

| KLWQD-2003 | G1600 | ≤20.0 | 130~2500 | ||||

| 250(10”) | KLWQD-2501 | G1000 | ≤20.0 | 80~1600 | 1.6 | carbon steel | |

| KLWQD-2502 | G1600 | ≤22.0 | 130~2500 | ||||

| KLWQD-2503 | G2500 | ≤25.0 | 200~4000 | ||||

| 300(12”) | KLWQD-3001 | G1600 | ≤22.0 | 130~2500 | 1.6 | carbon steel | |

| KLWQD-3002 | G2500 | ≤35.0 | 200~4000 | ||||

| KLWQD-3003 | G4000 | ≤45.0 | 320~6500 |

What Are Gas Turbine Flow Meter?

When the fluid flows into the Gas Turbine Flow Meter, it is rectified and accelerated under the action of a dedicated integrated rectifier for the air inlet. Since the turbine blades are at a certain angle to the fluid flow direction, the angular velocity of the turbine is proportional to the fluid volume flow at this time.

According to the principle of electromagnetic induction, a magnetic sensor is used to induce a pulse signal proportional to the volume flow of the fluid from the coaxial rotating signal wheel. The signal is amplified, filtered, and reshaped and enters the intelligent flow totalizer together with the temperature and pressure sensor signals. The micro-processing unit of the instrument performs arithmetic processing. The volume flow and total flow of the gas are directly displayed on the LCD screen.

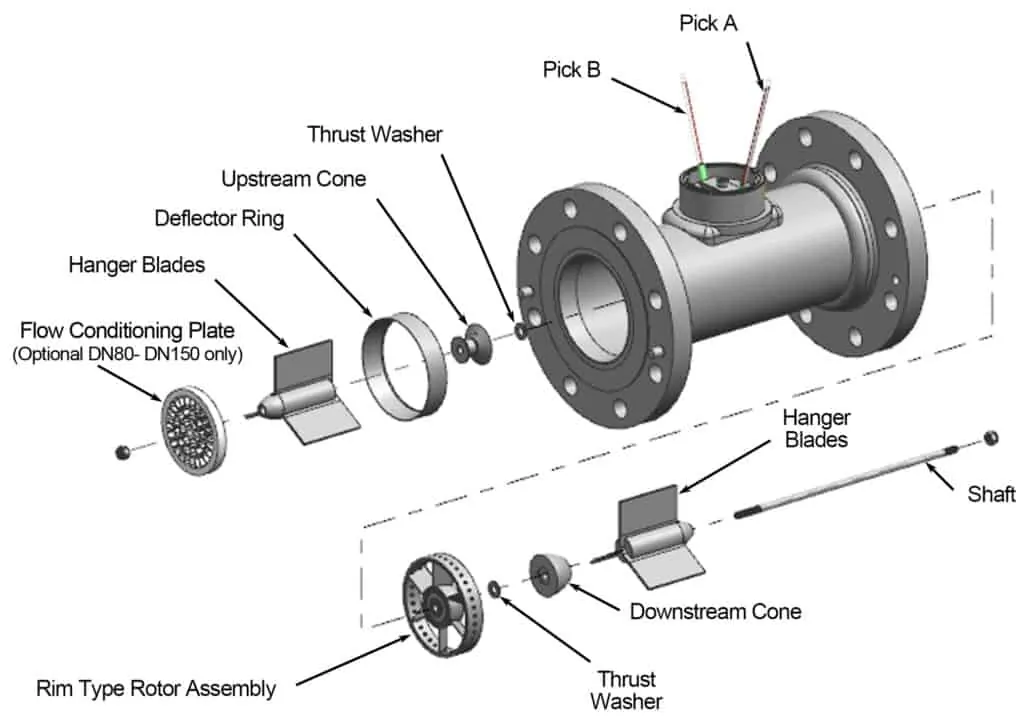

Please see the structure diagram below for the structure principle of Gas Turbine Flow Meter.

Gas turbine flow meter working principle

The gas turbine flowmeter uses a turbine for measurement. It first converts the flow rate into the rotational speed of the turbine, and then converts the rotational speed into an electrical signal proportional to the flow rate.

Gas turbine flowmeter is used to detect instantaneous flow and total integrated flow. Its output signal is frequency, which is easy to digitize.

The induction coil and the permanent magnet are fixed on the housing together. When the ferromagnetic turbine blade passes the magnet, the reluctance of the magnetic circuit changes, thereby generating an induction signal.

The signal is amplified and reshaped by the amplifier and sent to the counter or frequency meter. The total accumulated flow is displayed. At the same time, the pulse frequency undergoes frequency-voltage conversion to indicate instantaneous flow.

Extended reading: Quantitative control with turbine flowmeter

The speed of the impeller is proportional to the flow, and the number of revolutions of the impeller is proportional to the total amount of flow. The output of the turbine flowmeter is a frequency modulated signal. It not only improves the anti-interference of the detection circuit, but also simplifies the flow detection system.

The gas turbine flowmeter has a turndown ratio of up to 10:1, and the accuracy is within ±0.2%. The time constant of the turbine flowmeter with small inertia and small size can reach 0.01 second.

Extended reading: Threaded Vortex Nitrogen Gas Flow Meter

Gas turbine flow meters Applications

Gas turbine flowmeters are mainly used for gas flow measurement in industrial pipelines.

Flow measurement of air, nitrogen, oxygen, hydrogen and other media fluids.

When measuring the volume flow under working conditions, it is hardly affected by the fluid density, pressure, temperature, viscosity and other parameters.

Further reading: Nitrogen(N2) Flow Meter Types

Natural gas turbine flow meter

The gas turbine flowmeter has the characteristics of high sensitivity, good repeatability, large range ratio and high precision. Therefore, it is widely used in natural gas flow measurement.

When the flow rate changes greatly, the gas turbine flowmeter is more suitable than the differential pressure flowmeter.

The gas turbine flowmeter has a wide range ratio, medium and large diameters can reach 40:1 to 10:1, and small diameters are 6:1 or 5:1.

With the development of natural gas measurement technology and the increasing requirements for natural gas trade and transfer measurement, gas turbine flowmeters can not only meet the requirements of trade measurement, but also meet a wide measurement range.

In addition, its equipment cost is lower than orifice flow meters and gas ultrasonic flow meters.

Therefore, gas turbine flow meters are being used more and more widely. Especially China’s natural gas market usage has increased significantly. However, it is common in the downstream market that the initial consumption of natural gas pipelines is low. Large supply. Turbine flowmeter can reduce the diameter of the measuring tube due to its wider range ratio, thereby reducing investment.

The gas turbine flowmeter has high accuracy. The accuracy of ordinary flowmeters is (±1~±1.5)%, and the special type is (±0.5~±0.2)%. However, the higher the accuracy, the more demanding on-site conditions. harsh. Turbine flowmeter has good repeatability. Short-term repeatability can reach (0.05~0.2)%. If you calibrate regularly, you can get high accuracy.

The gas turbine flowmeter has a compact and light structure, convenient installation and maintenance, and large flow capacity. It is suitable for high pressure measurement.

There is no need to open holes on the meter body, and it is easy to make a high-pressure meter, which can meet the pressure increase requirements of the pipeline. Because of the above advantages, it is one of the preferred flow meters in natural gas trade settlement.

Extended reading: Turbine Insertion Flow Meter for Large Diameter Pipeline

Extended reading: Turbine Flow meter Vs Gear Flow meter

Sino-Inst’s Turbine Gas Meter offer reliable and accurate volume flow measurement in a large range of sizes and pressure rating while being fully compliant with international standards.

Sino-Inst is the risk-free choice for your gas flow measurement applications.

Sino-Inst supplies turbine flow meters, like: gas turbine flow meter. gpi turbine flow meter. liquid turbine flow meter. sanitary turbine flow meter. insertion turbine flow meter. steam turbine flow meter. and natural gas turbine flow meter.

Sino-Inst’s turbine flow meters, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, US, and other countries.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.