High Temperature & High Pressure level measurement, SIRD-705 GWR Level Sensor is a good choice. The highest pressure reaches 40MPa, and the highest temperature reaches 400℃.

The high temperature and high pressure guided wave radar level sensor is specially designed for high temperature and high pressure occasions. The product is mainly used for liquid level measurement on various boiler drums. Has high safety and accuracy. The highest rated pressure reaches 40MPa. The highest rated temperature reaches 400℃. It is suitable for high and low pressure heaters, condensers and deaerators in thermal power plants. As well as for liquid level measurement under high temperature, high pressure, vacuum and other steam conditions.

Sino-Inst offers a variety of Guided wave radar Level Sensors for industrial high temperature and high pressure level measurement. If you have any questions, please contact our sales engineers.

Features of GWR High Temperature Liquid Level Sensor

GWR Level Sensor has the advantages of low maintenance, high performance, high precision, high reliability and long service life. Compared with contact instruments such as capacitors and heavy hammers, it has unparalleled advantages.

The transmission of microwave signals is not affected by the atmosphere. Therefore, it can meet the requirements of harsh environments such as volatile gases, high temperature, high pressure, steam, vacuum and high dust in the process.

GWR Level Sensor is suitable for harsh environments such as high temperature, high pressure, vacuum, steam, high dust and volatile gases. It can continuously measure different material levels.

The main technical indicators of GWR Level Sensor meet or exceed similar products at home and abroad. It is easy to install and debug. It can be used alone or in a network. It can be widely used in metallurgy, building materials, energy, petrochemical, water conservancy, food and other industries.

GWR Level Sensor measurement advantages:

- It has a strong ability to suppress steam and foam, and the measurement is not affected;

- Not affected by liquid density, loose degree of solid material, temperature, and dust during feeding;

- Low maintenance, high performance, high precision, high reliability and long service life.

Specifications of SIRD-705 GWR Level Sensor for High Temperature & High Pressure

| Suitable for Medium: Liquids, especially high temperature and pressure environment of liquid |

| Application: Sealed tanks, high pressure liquid measurement |

| Explosion-proof Grade: Exia IIC T6 Ga/Exd IIC T6 Gb Measuring |

| Range: 15m |

| Frequency: 500MHz-1.8GHz |

| Antenna: Single cable or single rod antenna |

| Accuracy: ±10mm |

| Process Temperature:(-200~400)℃ |

| Process pressure:(-0.1~40)MPa |

| Signal output:(4~20)mA/HART |

| The Scene Display: Four LCD/Can be programmed |

| Power Source: Two-wire (DC24V) |

| Four-wire(DC24V/AC220V) |

| Shell: Aluminum /Plastic |

| Connection: Thread / Flange (optional) |

GWR Level Sensor for High Temperature & High Pressure Applications

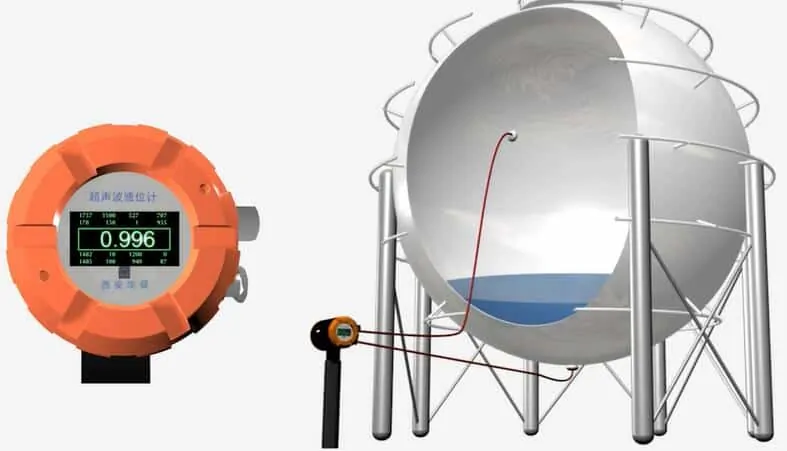

SIRD-705 GWR Level Sensor is suitable for measuring liquids with high pressure in sealed tanks, especially liquids in high temperature and high pressure environments.

It is suitable for high-pressure bubble water level measurement in power plants, liquid ammonia measurement, and liquid level measurement in chemical fertilizer synthesis ammonia process.

Advantages of using guided wave radar level sensors on boilers

Guided wave radar level sensor is often used in industrial production. Because of its superior performance, it is accepted by the public. It has the advantages of low maintenance cost, strong detection performance, accurate measurement accuracy, high safety, and long service life. The signal emitted by the device is not affected by the environment, atmosphere. So it can be used in a variety of special media, such as high temperature, high pressure, steam state, volatile gas, dust, vacuum environment, etc.

Today I want to share with you how to use the guided wave radar level sensor in the boiler. The high temperature and high pressure in the boiler need to use the level sensor to measure the internal liquid level to ensure its safety. The use of guided wave radar level sensors can solve the difficult problems of safety, accurate readings, and simple maintenance.

On some boilers, each boiler installation requires at least two independent water level sensors. Therefore, each boiler also needs to be equipped with two guided wave radar level sensors. Only in this way can the safety requirements for boiler operation be fully met. Guided wave radar level sensors need to use quartz tubes to observe changes in the liquid level in the furnace. However, the connecting pipes and valves need to be opened to improve the accuracy of detection. It is necessary to ensure that the probe and sensor are dry and clean during installation. If contamination occurs, it can not be wiped with a wet towel, and alcohol must be used for decontamination.

Although many cities do not yet have standard regulations on boiler level sensors. At least one intuitive level sensor must be installed, together with a guided wave radar level sensor for observation. If it is a large and complex complete set of boiler equipment, it is necessary to redesign and plan the guided wave radar level sensor and install it according to the design drawing.

If you need to measure river water level, open channel level, etc. The Ultrasonic Liquid Level Sensor can be used for non-contact continuous level monitoring.

Extended Reading: Case: High Temperature Radar Level Transmitter for Melted Salt-Solar Photovoltaic Power Station

Float Type Level Switches

Continuous Level Sensor Series

Continuous level sensors are transmitters that measure liquids within a specified range. Level sensors determine the exact amount of liquid that provides a continuous analog signal. The level signal can be displayed directly on site or integrated into a process control or management system. These products can be installed vertically and horizontally. They are ideal for monitoring liquids in confined or restricted areas.

Frequently

Asked

Questions

Sino-Inst offers over 10 Guided Wave Radar level transmitters for level measurement. About 50% of these are Radar level meters, 40% is the tank level sensor.

A wide variety of Guided Wave radar level meters options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Guided Wave radar level measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.