What is a piston flow meter?

A piston flow meter is a positive displacement flowmeter, which is mainly used to measure liquid flow. The piston flow meter is composed of a shell, piston mechanism, and other parts. The measured fluid fills a space with a certain volume, and these volume increments are counted and accumulated. It has the advantages of simple structure, reliable work, high accuracy, large range ratio, and little influence on viscosity. It is mostly used for measuring non-corrosive liquids, such as heavy oil or other oils, on small-diameter pipelines.

Piston flow meter technology

Piston-type flowmeters are commonly used for flow measurement of fuel dispensers. Its structure includes a housing, an upper cover, a lower cover, a piston, a crankshaft, and a distribution valve. The inner cavity of the housing is equipped with four-piston cylinders that cooperate with the piston dynamic seal. The four-piston cylinders are evenly distributed in the circumferential direction on the vertical plane of the crankshaft rotation centerline.

The piston is connected to the crankshaft by a connecting rod. The piston rodless cavity is connected to the inlet and outlet on the upper cover through the distribution valve. A side cover is installed on the casing outside the piston cylinder. The upper cover is equipped with an output shaft that rotates synchronously with the crankshaft. By right Count the number of revolutions of the output shaft to achieve flow measurement.

- The main disadvantages are:

- The outer circular surface of the output shaft of the existing piston flowmeter and the upper cover adopts O-ring dynamic sealing cooperation.

- The high-speed rotation of the output shaft is likely to cause wear to the sealing ring, resulting in a decrease in sealing performance and even leakage.

- In addition, there are errors in the machining dimensions of the inner cavity of the piston-cylinder of each product. Lead to the measurement error of the piston flowmeter.

Read more General-purpose Flow Totalizer for Data collection and calculation

Features and applications of Piston flow meter

The piston flow meter has a simple structure, reliable work, and a large measuring range.

The measurement accuracy is high and is not affected by viscosity. It can be changed remotely and other advantages.

However, the main components of the measurement part are not corrosion-resistant. Therefore, it can only measure non-corrosive media, such as heavy oil and other petroleum products.

Extended reading: Cylinder Gear flow meter for micro flow measurement.

Piston flow meter working principle

A piston flow meter is a positive displacement flow meter, which is based on the fact that the piston and the metering chamber have been kept in a tangential sealed state. And there is a fixed eccentric distance metering element piston.

Under the action of the pressure difference, a rotational torque is generated on the piston, which makes the piston perform an eccentric rotation movement.

The number of revolutions of the piston is proportional to the flow rate of the fluid. The piston revolution ratio is recorded by the counting mechanism. Then the total flow of fluid can be measured.

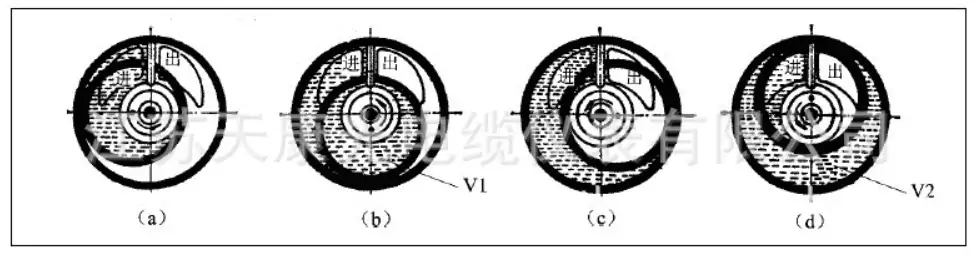

The inlet and outlet of the Piston flow meter are separated by a partition. When the measured fluid enters the metering chamber from the inlet, a pressure difference is formed at the inlet and outlet, forcing the piston to rotate counterclockwise as shown in the figure.

The continuous flow of fluid forces the piston to rotate as shown in the figure, forming two and a half-crescent cavities. The piston is forced to rotate under the action of the pressure difference as shown in the figure. V2 fluid is discharged from the outlet. Rotate under the action of pressure difference. V1 fluid is discharged from the outlet, and the fluid bursting out every revolution of the piston is equal to the sum of V1+V2.

Tool: Volumetric Flow Rate & Pipe Diameter to Flow Speed Calculator

Piston flowmeter output signal, such as 4-20mA. The flow signal can be connected to a paperless recorder. Carry out multi-channel flow signal monitoring. What Is A Paperless Recorder?

Piston flowmeter VS gear type flowmeter

Gear flow meters are a type of positive displacement flow meters, used for precise continuous or intermittent measurement of the flow or instantaneous flow of liquid in the pipeline. It is especially suitable for the flow measurement of heavy oil, polyvinyl alcohol, resin, and other high viscosity media.

Piston type flowmeter is an online installation, mechanical flow switch, used for liquid or gas medium. Very small pressure loss, good repeatability, anti-fouling ability, mechanical part, and electronic part are completely isolated, suitable for small flow economy type.

If the flow rate you want to measure is not large, the piston type is better.

If you want to measure a large flow rate, just use a gear type.

If the gas flow is measured, only the piston type can be used

Extended reading: Positive displacement flow meter working principle.

Guess you like: What is Reynolds number?

A Piston Flow Meter is an innovative device that accurately measures fluid flow in pipelines. Sino-Inst, a well-established manufacturer and supplier of Piston Flow Meters, boasts a wealth of experience in the field.

With our top-notch product line, Sino-Inst is the perfect partner for all your flow measurement needs. If you’re in the market for a reliable and efficient Piston Flow Meter, look no further! Contact Sino-Inst today and let them show you what they can do.

And that’s not all, Sino-Inst also offers a range of other flow meters, including turbine flow meters, magnetic flow meters, and more. Let Sino-Inst help you find the perfect flow meter solution for your specific application!

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.