A flow meter is an instrument used to measure and indicate the volume or mass of a gas or liquid. Simply put, it is an instrument used to measure the flow of fluid in pipes or open channels. Also known as flow indicator, liquid flow meter, flow sensor, etc.

Flowmeters are further divided into differential pressure flowmeters, rotameters, throttling flowmeters, slit flowmeters, volumetric flowmeters, electromagnetic flowmeters, ultrasonic flowmeters, etc. According to the medium, it can be divided into: liquid flowmeter and gas flowmeter.

What is Flow Meter Calibration?

Flow meter calibration is carried out according to the verification regulations of various flow meters promulgated by the National Metrology Bureau.

For the flowmeters used, except for the standard throttling device, no experimental verification is required. The rest of the flowmeters are almost all verified when they leave the factory. During the use of the flowmeter, it should also be calibrated frequently.

The calibration methods of liquid flowmeter mainly include volumetric method, mass method, standard volume tube method and standard flowmeter comparison method.

The calibration methods of gas flowmeter mainly include sonic nozzle method, servo standard flowmeter comparison method and bell jar method.

Why is it important to calibrate a flow meter?

Most people recognize that a flow meter should be calibrated before it is put into service, but why is flow meter calibration so important?

The flow meter calibration process involves comparing the flow meter to a reference device used as a calibration standard. Calibration of reference equipment should be traceable to national or international standards. The next step involves adjusting the flow meter (if necessary) to counteract any errors.

If, like thousands of other facilities, flow meters are used in your process, it makes good business sense to ensure that the flow meters you use are giving you accurate and consistent information.

No matter what fluid you are metering, the liquid, gas or steam used in the process is most likely a valuable commodity. Accurate flow meter performance is therefore an invaluable part of business planning and costing.

At the same time, Calibration Flow Meters are also very important for the control of material consumption in our industrial production process. Can effectively improve production efficiency. reduce manufacturing cost.

Flow Meter Calibration vs. Recalibration

Flow Meter Verification (Verification): Refers to the process of identifying and confirming whether measuring instruments meet the statutory requirements. It includes inspection, marking and/or issuing a certificate.

Flow Meter Calibration (Calibration): refers to the determination of the value indicated by a measuring instrument or measuring system, or the value represented by a physical measuring tool or reference material, and the corresponding value reproduced by a standard under specified conditions. A set of operations on relationships.

After reading the definition, there must be some confusion, right?

We usually summarize the main differences between verification and calibration into nine aspects:

- Different purposes;

- Objects are different;

- According to different;

- Different in nature;

- The cycle is different;

- In different ways;

- The content of the certificate is different;

- Different conclusions;

- The authorities are different.

For quick understanding, we simply organize the following table:

| Verification and Calibration | Verification | Calibration |

| Definition of Terms | Refers to the process of identifying and confirming whether measuring instruments meet the statutory requirements, which includes inspection, marking (or) issuing a verification certificate. | Refers to a set of operations to determine the relationship between the value indicated by a measuring instrument or measuring system, or the value represented by a physical measuring tool or reference material, and the corresponding value reproduced by the standard under specified conditions . |

| Character | It belongs to mandatory verification and has legality; | Users can voluntarily trace the source, which is not legal; |

| Certificate form | If the test result is qualified, a “Certificate of Test” shall be issued; If it is unqualified, a “Notification of Verification Result” shall be issued | Usually a “Calibration Certificate” or “Calibration Report” is issued; calibration results can also be expressed in the form of calibration curves or calibration factors |

| Specific method | According to the verification regulations, each point is verified 3 times at 100%, 50%, 20% and 100% of the full scale. If the original coefficient is qualified, the coefficient is not adjusted in principle. | According to the calibration procedure, at 100%, 50%, 20% and 100% of the full scale each point 3 times, adjust the coefficient to obtain the best performance near the user’s actual flow. The nameplate remains the same, but the certificate reflects the change. |

How to Calibrate a Flow Meter?

Read more about: 5 Factors Affecting Pressure Drop

Field Calibration Method You Must Know

Many users search How to Calibrate a Flow Meter? In order to understand how to adjust the accuracy of the flowmeter in your own working conditions.

On-site “flow comparison” means that the flowmeter is compared with other “reference flows” on site.

For example, the measured value of the temporarily clamped ultrasonic flowmeter, the volume of the liquid that has been measured over the flow in the piping system, etc. can be used as the “reference flow”.

For the meaning of terms such as on-site calibration, comparison and verification, please refer to the standard definitions in relevant documents, and will not repeat them here.

In practice, many professionals have explored various on-site comparison methods and indirect inspection methods. There are mainly 3 types:

(1) Use the container weighing method comparison of storage containers, working containers, pools or weighing instruments in the process. The pool volume comparison method is often used by water supply companies. Water plants can obtain high comparison accuracy by taking advantage of the favorable conditions of large-volume clear water pools.

(2) Reserve a position in the pipeline of the flowmeter to be tested for the flowmeter comparison method of connecting the reference flowmeter.

(3) Ultrasonic flowmeter comparison method of Clamp-on ultrasonic transducer. Clamp-on ultrasonic flowmeter is one of the three most promising methods of flow measurement. Especially the measurement accuracy error of existing foreign products is < ± 0.5%. This is conducive to the establishment of high-precision comparative detection and on-site online calibration system. It is convenient for the metrology and verification department to go to the site for calibration and testing.

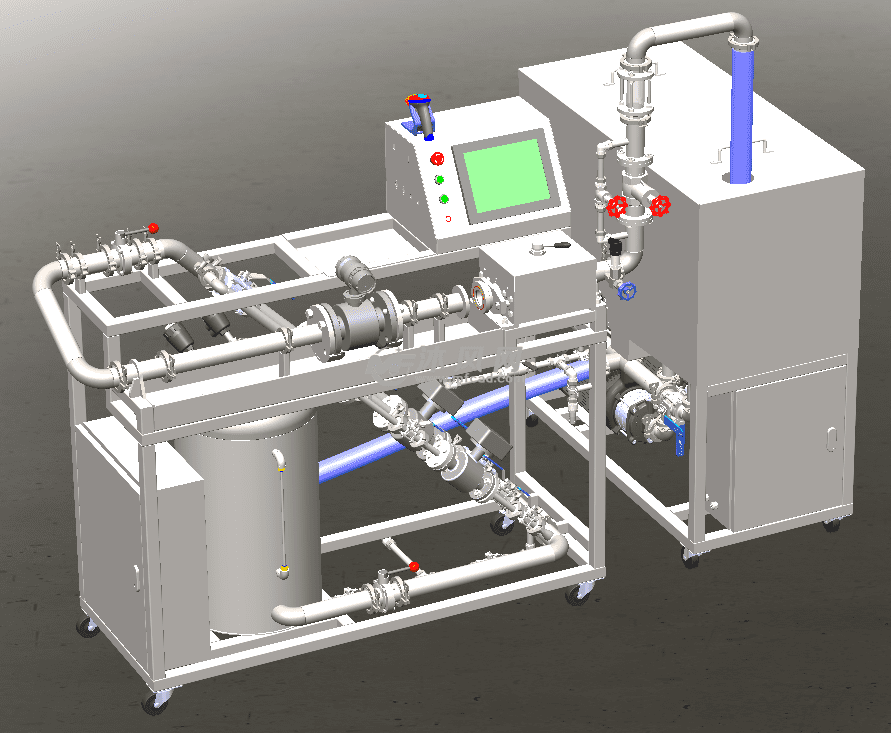

Featured Calibration Flow Meters

More Featured Flow Measurement Solutions

The above is “How to Calibrate a Flow Meter?” I hope it will be helpful to everyone.

Flowmeter calibration method is the trend of measurement technology development. In particular, the use of portable ultrasonic flowmeters to carry out online flowmeter calibration is a feasible method. It can greatly facilitate the on-site measurement and calibration work. It can effectively reduce the capital consumption in metering and is easy to popularize and apply.

The data shows that through the research and application of on-site calibration technology for flow metering instruments. Can improve the measurement detection level. , to achieve the purpose of periodic measurement verification. To make the online flowmeter measurement data accurate and reliable, as long as it is operated accurately. Minimize random and additive errors. It can meet the requirements of the relevant state departments for the accuracy of industrial and civil water measurement.

Sino-Inst is a manufacturer of Calibration Flow Meters. We offer more than 50 Calibration Flow Meters.

Sino-Inst provides customers with professional and targeted system solutions to help customers solve various problems encountered in production, optimize control and improve product quality.

If you need to purchase flowmeters, or consult technical questions about flowmeters, please feel free to contact us.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.