Underground tanks refer to tanks installed below the ground for storing gas or liquid. So is measuring the level of an underground tank the same as measuring the level of a tank above ground? The answer is no. Most underground tanks come pre-assembled. Once installed, it will not change year after year. The most common ones are underground oil storage tanks at gas stations.

So how to measure the liquid level of underground tanks? What tank level indicators are available? Let’s take a look together.

Underground tanks are generally installed pre-buried. After installation, it is difficult to make changes to the bottom, sides, etc. of the tank. Of course, underground tanks generally have reserved manholes, feed openings, discharge openings, etc. Some will also reserve installation locations specifically for level meters.

Based on our experience, underground tank level indicators can be divided into two categories: contact and non-contact. For example, ultrasonic level meter and radar level meter are commonly used non-contact level indicators. For example, Hydrostatic Level Sensor, float level sensor, and magnetostrictive level meter are commonly used contact level indicators.

The specific choice needs to be determined based on the conditions of the medium in the storage tank. The second half of our blog will explain this with examples.

Below are the various underground tank level indicators we supply at Sino-Inst. You can choose to delve deeper into the measurement parameters:

Available underground tanks level indicators

OK Next, we will use our actual cases to hand over the choice of underground tank level indicators for you.

Gas station underground oil storage tanks

We all know that most diesel and gasoline at gas stations are stored in underground tanks. The oil level needs to be accurately monitored in real time. Including when feeding and discharging materials. The accuracy of this tank level indicator needs to be very high. Because it is directly linked to money.

So based on our experience, in this case we would recommend users to choose Magnetostrictive liquid level sensor.

Mainly because Magnetostrictive liquid level sensor can meet the following characteristics:

- Large range: 0.2m~25m;

- Meet the explosion-proof requirements of gas stations. Explosion-proof level: ExdⅡCT6 Gb;

- High precision. Magnetostrictive level transmitter has a maximum accuracy of 1mm;

- Can meet high temperature, high pressure and other parameter customization. -40 ℃ ~ +350 ℃, 10MPa;

- The installation size can be customized. According to the installation requirements of underground oil storage tanks, threaded or flange installation can be configured.

- Support signal output, 4~20mA, 0~5V, 0~10V, HART, RS-485. It is convenient for real-time monitoring of oil level in the office.

- The Magnetostrictive level transmitter can also be customized according to needs: interface output (measurement of oil-water interface), and simultaneous output of temperature and liquid level (up to 8 RTD temperature sensors can be installed for temperature detection).

Read more about: Magnetostrictive Level Transmitter Working Principle

Of course, if the measurement accuracy requirements are not high. Then it is also possible to choose explosion-proof ultrasonic level meter.

Underground sewage storage tanks

Here is an example of a measurement taken by one of our users. Their 2 storage tanks are underground tanks for sewage.

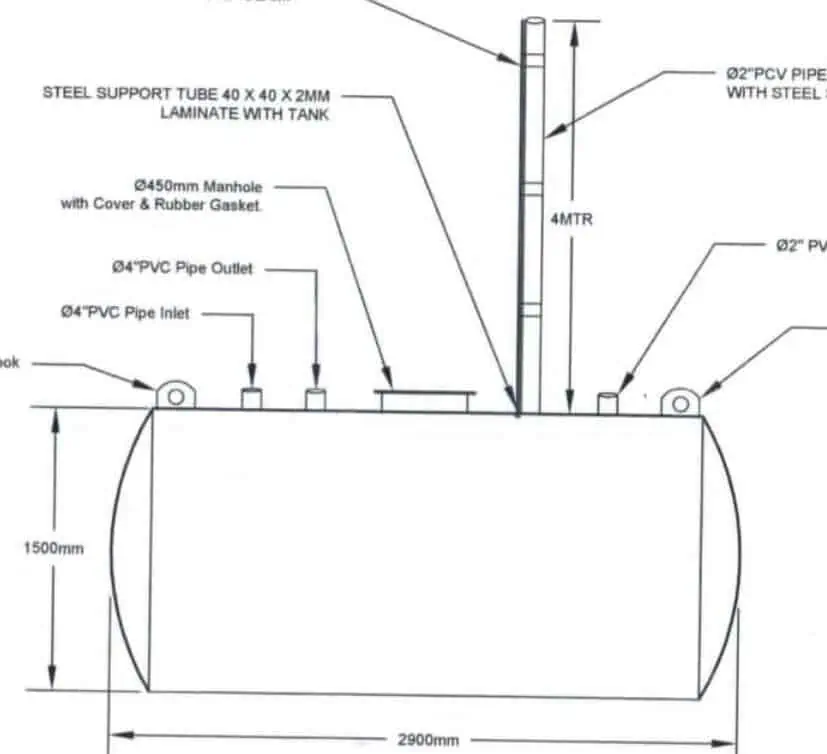

- The 2 storage tanks are sewer septic tanks;

- The on-site storage tanks are underground storage tanks; horizontal tanks; the heights are 1800mm and 1500mm respectively;

- The tank has a reserved manhole of Φ450mm.

Comprehensive consideration of measurement parameters and installation dimensions. We configure anti-corrosion antennas for the optional 80G radar level meter. Customized installation dimensions for reserved manhole installation in the tank.

Read more about: Crude Oil Measurement, 80G Radar Level Meter Should Be Your First Choice!

Chemical corrosive raw material storage tanks

The capacity of underground storage tanks in the chemical industry can range from thousands to millions of gallons. For example, some large chemical plants may have underground storage tanks with a capacity of 300,000 gallons for storing raw materials such as ethylene and benzene.

This type of Underground Tanks level measurement will be more complicated than the above two. We need to comprehensively consider many factors, especially the characteristics of the medium:

- The size and shape of the tank.

- The temperature, pressure, viscosity, corrosiveness, etc. of the medium.

- Is there stirring in the tank?

- The installation position of the inlet and outlet, etc.;

Here we discuss the level indicators available for corrosive media. Generally there are radar level meters and guided wave radar level meters. Or customize an anti-corrosion input level sensor made of PTFE.

The following is also a case of measurement by one of our customers. The measuring medium is: a metal tank containing 98% sulfuric acid. The tank is large and comes with a picture of the level transmitter installed.

We equipped him with an antenna made of PTFE anti-corrosion material to meet the measurement requirements:

Radar level meter

Model: FMW11

80G

Measuring the level in a sulfuric acid tank

PTFE antenna,

Temperature resistance: -40-80℃,

Pressure: -0.1-0.3MPa

Mounting Dimensions: 1 1/2″ NPT PTFE Coated

Digital display with measurement and programming

24VDC

4-20mA (two wires) +HART

1/2″ NPT Head Electrical Connections

FAQ

More Level Measurement Solutions

- Cryogenic Level Sensor for Liquid Nitrogen Tank Level Indicator

- Underwater Pressure Transducer|IP68-for Underwater Pressure or Level Measurement

- Wastewater Level Sensor for Septic Tank-Sewage Holding Tank

- Water Level Monitoring Sensor/System for Sewage-Wastewater

- Sulfuric Acid Storage Tank Level Measurement-Radar Level Sensor

- Water Tank Level Sensors for Level Control

- Oil-water Interface Level Measurement Guide

- Ultrasonic Water Level Sensors

- Explain the difference: Float level sensor, Float level switch and Float level controller

- CO2 Cylinder | Portable Liquid Level Gauge

- Level Measurement: Liquid Chlorine Storage Tanks

- Inaccurate level measurement of liquid ammonia storage tank

- Use Differential Pressure Transmitter to Measure Liquid Level

- External Ultrasonic Tank Level Sensor

- 7 Type Tank Level Senors For Liquid and Solid

- Guide to Ultrasonic Level Transmitters-for Continuous Non Contact Level Measurement of Liquid & Solids.

An important reason for using underground storage tanks is that they can reduce the occupation of surface space. At the same time, they have certain functions of thermal insulation, fire prevention and reducing environmental pollution. However, underground storage tanks also require strict compliance with environmental regulations and safety standards to prevent leaks and contamination of soil and groundwater. Liquid level monitoring of underground storage tanks can effectively avoid economic losses.

We at Sino-Inst are professional suppliers of Underground Tanks level indicators. We provide users with various standard and customized level meters. It can meet the liquid level measurement needs of various tanks with different parameters.

If you need to measure Underground Tanks level, please feel free to contact our sales engineers for consultation.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.