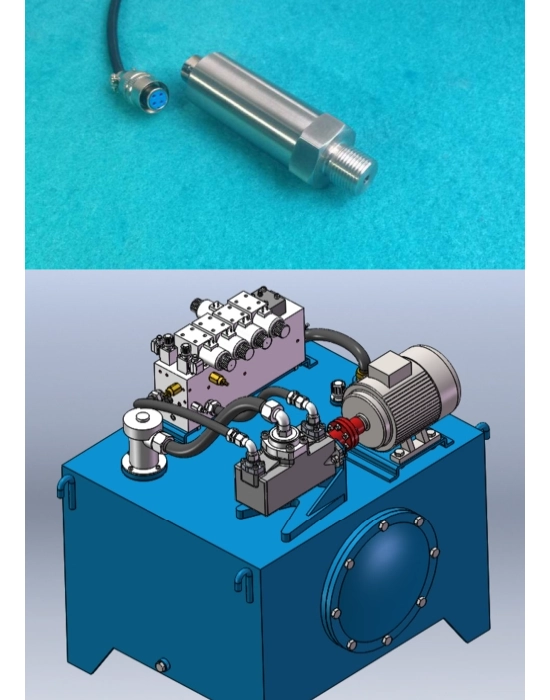

What is a hydraulic pressure transducer?

A hydraulic pressure sensor is a sensor used to measure pressure in a hydraulic system. It can monitor and control the pressure of the hydraulic system by converting the pressure into electrical signals. to ensure the pressure within the system is at the correct level, or to allow the controller to increase or decrease pressure.

Hydraulic Pressure Transducers are used in a variety of hydraulic systems such as power steering systems, shock absorbers, braking systems, utility vehicles such as excavators and aerial work platforms, lifts and industrial machinery such as hydraulic presses.

As a manufacturer of pressure transmitters, we at Sino-Inst supply a variety of Hydraulic Pressure Transducers. Including customized high pressure, high temperature, and other product parameters. The product list below is for your reference.

Hydraulic Pressure Transducers

hydraulic pressure transducer Applications

Hydraulic pressure transducer is a device that converts hydraulic signals into electrical signals and is widely used in a variety of hydraulic systems and industrial processes. The following are several main applications of hydraulic pressure sensors: booster cylinders, superchargers, gas-liquid booster cylinders, gas-liquid boosters, presses, compressors, air conditioning and refrigeration equipment and other fields.

- Hydraulic system monitoring and control: Hydraulic pressure sensors can be used to monitor the working pressure in the hydraulic system to ensure its normal operation. When the pressure reaches or exceeds the set upper or lower limit, the alarm or control system can respond. Such as adjusting the output of the pump, opening or closing valves, etc.

- Aerospace applications: In the hydraulic systems of aircraft and spacecraft, pressure sensors are used to ensure the normal operation of the system. Monitor the pressure status of the aircraft landing gear, brakes and flight control systems.

- Automobile industry: In the hydraulic brake system, power steering system and suspension system of automobiles, pressure sensors may be used to ensure the normal operation and safety of the system.

- Industrial automation and manufacturing: In production lines, injection molding machines, pressure forming machines and other equipment, hydraulic pressure sensors are used to monitor and control the process to ensure product quality.

- Medical Equipment: In some medical equipment, such as cardiac assist equipment, hydraulic pressure sensors are used to monitor and control the flow and pressure of hydraulic fluid.

- Energy and power industry: In power stations and renewable energy equipment, hydraulic pressure sensors can be used to monitor the pressure of liquid media (such as hydraulic oil) to ensure normal operation of the equipment.

Hydraulic Pressure Transducers Installation

The installation location of the hydraulic pressure sensor should be determined based on the actual conditions of the hydraulic system. Generally speaking, the sensor should be installed at the most important position in the hydraulic system to monitor the highest pressure of the hydraulic system.

Common installation locations include the following:

- Pump outlet: Installed at the pump outlet, the output pressure of the pump can be monitored to ensure the normal operation of the pump.

- The inlet of the oil cylinder: Installed at the inlet of the oil cylinder, the pressure of the oil cylinder can be monitored to ensure the normal operation of the oil cylinder.

- The outlet of the oil cylinder: Installed at the outlet of the oil cylinder, the output pressure of the oil cylinder can be monitored to ensure the normal operation of the oil cylinder.

- High-pressure side of the oil line: Installed on the high-pressure side of the oil line, the highest pressure of the entire hydraulic system can be monitored to ensure the normal operation of the hydraulic system.

More about Pressure Transmitter Installation Guide.

FAQ

More Pressure Measurement Solutions

What Is Pressure Transducer Output Signal? and Types

Optimize Filtration Monitoring with Differential Pressure Sensors

Low Cost Differential Pressure Sensor – Solve Big Problems!

Oxygen Cleaning Pressure Sensor – No Oil, No Corrosion, No Impurities

Voltage Pressure Transducer Comparison

What Is a Differential Pressure Sensor?

The Hydraulic Pressure Transducer is a transducer used to measure pressure in hydraulic systems. It can monitor and control the pressure of the hydraulic system by converting the pressure into electrical signals. It is essential for the safe operation of hydraulic systems. By understanding its working principle and correct use method, you can better utilize its characteristics and improve production efficiency and work safety.

Sino-Inst is a professional Hydraulic Pressure Transducer manufacturer. Our Hydraulic Pressure Transducers are widely used in various industrial hydraulic systems. If you need to purchase Hydraulic Pressure Transducers or have related technical questions, please feel free to contact our sales engineers!

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.