Hydrostatic level measurement is often used for tank level measurement. Hydrostatic level measurement is one type of continuous level measurement.

What Is Hydrostatic Pressure?

Hydrostatic pressure sensors are used to measure the level or fill height of liquids. Hydrostatic pressure measurement is suitable for liquid level measurement due to the static pressure effect of non-flowing fluids. This physical principle describes the effect of the gravity of a stationary (i.e. non-flowing) liquid on the measurement point. This gravity is often described as “hydrostatic pressure”.

Sino-Inst offers a variety of Hydrostatic level senors for industrial level measurement. If you have any questions, please contact our sales engineers.

Select a Featured hydrostatic level sensor for your application

Hydrostatic Level Sensor (Best Price), also called Hydrostatic level transmitter. Continuous level measurement in liquid applications with pressure sensors.

Liquid pressure sensor is widely used for pressure measurement of various liquids. Like water or oils. IP68 waterproof.

Submersible pressure transducer with 4-20mA output,

is normal submersible pressure transmitter for level measurement.

Hydrostatic level transmitter is also called hydrostatic level gauge. The rod-type Hydrostatic level transmitter 4-20mADC standard signal output. Flange or threaded installation. Can withstand high temperatures up to 450 ℃.

Well water level sensor is to apply Hydrostatic Level Sensor to deep well. Well water level sensor submerged in deep well work together with submersible water pump. Range 300m ~ 1000m.

Submersible Level Transmitter is made of Anti-corrosive all-tetrafluoroethylene(PTFE) material. It has high temperature resistance, corrosion resistance and anti-clogging.

Stainless Steel Level Sensor-Pressure Guided Submersible Level Transmitter. The sensor part and the signal processing circuit are inside the junction box. It is used for high temperature, corrosive liquid, sewage, etc.

The above level sensors are Submersible Level Transmitters. According to your measurement needs, we can provide various customizations. For example: measuring range, installation method, output method, explosion-proof, lightning protection, anti-corrosion, etc.

If you cannot use a level probe, we recommend that you use a pressure level sensor.

Extended reading: sludge level measurement

Hydrostatic level measurement with Pressure Transmitters

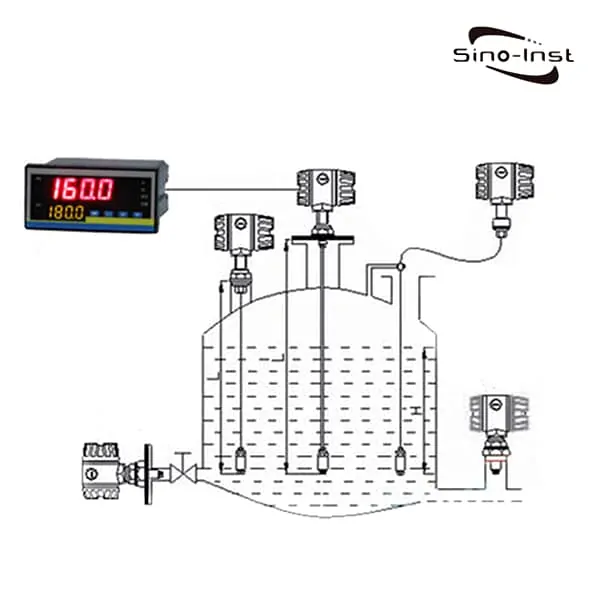

In open and closed tanks, there may be special conditions such as high temperature and corrosion. At this time, use a pressure or differential pressure transmitter, with flange, diaphragm, capillary, etc. We can achieve the static pressure measurement of the tank liquid level.

Pros & Cons of Hydrostatic level measurement system

About Hydrostatic level transmitter advantages and disadvantages, we do a simple analysis here. If you want to know more about the advantages and disadvantages of level transmitters. Please refer to Sino-Inst Level Transmitters.

Advantages

- High measurement accuracy;

- The ultra-high range can be customized up to 1000 meters.

- Easy to install;

- The signal can be transmitted remotely;

- The corrosion of various media can be resisted by choosing different materials;

- Suitable for explosion-proof occasions;

- Low cost;

Disadvantages

- The measurement signal needs to be converted;

- When the measuring range is greater than 5 meters, it is impossible to measure the high temperature medium temperature exceeding 125 ℃;

- The density of the measuring medium must be uniform.

Hydrostatic level sensor installation guide

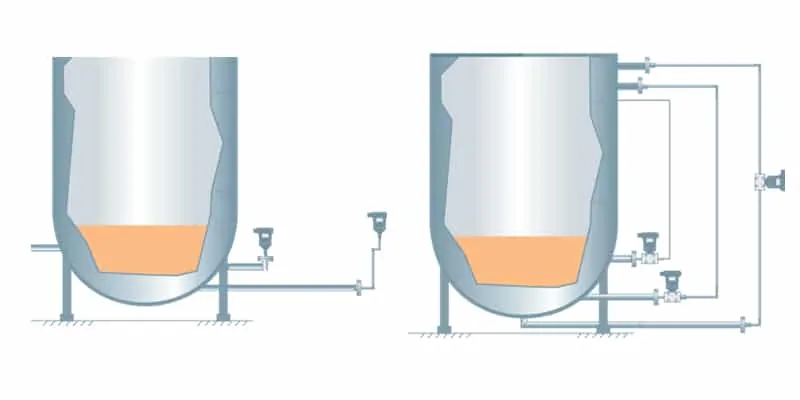

- If you choose a submersible pressure transmitter. You must lower the device into the medium by cable. Until you reach the bottom of the tank, reservoir or underground resources, or until you reach the required zero level. Then, run the cable from the oil tank or water tank to the control system. Connect the level probe to the PLC accordingly.

- If you have turbulent media, you should use an extra tank weight to stabilize the level probe in the media. To obtain a stable pressure reading. To prevent the cable from any mechanical damage. You can use the cable clamp to fix the cable on the top of the water tank. Or when connecting the cable to the control system.

- If you choose a standard pressure transmitter. Simply screw the transmitter into the threaded hole on the bottom or side of the tank. Then, connect the transmitter to the PLC with the appropriate cable connector. Or if cable connection is selected, connect the transmitter directly to the control system.

Hydrostatic level sensor can also be used with paperless recorder.

Capacitive vs Hydrostatic level sensor

Capacitive liquid level transmitter is the core sensor working principle of a transmitter. Refers to an instrument that measures differential pressure by detecting changes in capacitance on both sides of the sensing diaphragm. Theoretically, it can measure the pressure and differential pressure in any form, including liquid level. The reason why it is called a liquid level transmitter is only because its installation method is specially designed for liquid level measurement. The essence of the capacitive liquid level transmitter is a differential pressure transmitter.

Hydrostatic level sensor refers to a method of measuring liquid level using the principle of Hydrostatic pressure. Liquid level height × medium weight = pressure difference between liquid level and upside. This method of measurement requires the use of a differential pressure transmitter. If this differential pressure transmitter is designed to be more suitable for liquid level measurement, it is called a liquid level transmitter.

Extended reading: Hydrostatic Pressure Transmitter

Frequently

Asked

Questions

Related Blogs

Hydrostatic level sensor price

Compared with other liquid level transmitters, Hydrostatic level esnsor has lower cost. The price of Hydrostatic level sensor is mainly affected by the measurement situation. Such as:

- Range range;

- Medium temperature;

- The medium is corrosive;

Sino-Inst is a manufacturer of Hydrostatic level sesnor. Sino-Inst provides customers with the best Hydrostatic level measurement price. For example, the general-purpose Hydrostatic level transmitter has a reference price of USD70. If you want to know the exact price, please contact our sales engineer.

Sino-Instrument offers detailed product specifications and data sheets for review. Our application engineers, can help ensure you choose exactly what you need for your specific installation. Or if you need the RFQ instantly, we can offer you with the submersible level transmitter price immediately.

Extended Reading: bin level measuring system

Sino-Inst offers over 50 Hydrostatic level sensors at best price.

About 50% of these are Submersible Pressure Transducer, 40% are Differential Pressure Gauge, and 40% are Diaphragm Seal Pressure transmitters.

A wide variety of Submersible Pressure Transducer options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of

Submersible Pressure Transducer, located in China. Sino-Inst sells through a mature distribution network that reaches all 50 states and 30 countries worldwide. Submersible Pressure Transducer products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.

Readd more about: [What is and How it Works]Hydrostatic Level Sensor

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.