What is a gas pressure sensor?

Gas Pressure Sensors are also called Gas Pressure Transducers. Gas Pressure Sensors convert gas pressure into standard electrical signals, such as 4~20mADC. Measurement, indication and process adjustment are carried out by supplying secondary instruments such as indicating and alarming instruments, recorders, and regulators.

Gas pressure measurement is widely used in the field of industrial process control for process control and monitoring. Different gases have different properties, so different pressure sensors and transmitters are required to measure different gas pressures. For example, measuring oxygen, hydrogen, chlorine, compressed air, high temperature gas, etc.

gas pressure measurement

Gas pressure sensors are designed (or configurable) to measure gas pressure in different ways. In industrial settings, they can be used to measure the velocity of gas flow (sometimes called “shock pressure”), confirm the presence of suction, manage source pressure, or test for leaks.

(1). Gauge pressure is measured relative to ambient atmospheric pressure. Atmospheric pressure at sea level is about 100kPa (14.7 PSI). Sensors built into tire air pumps measure pressure this way, showing the air pressure inside the tire relative to the local atmospheric pressure. A reading of zero indicates equal internal and external pressure.

(2). Sealed air pressure sensors are similar to gauge air pressure sensors. But are pre-calibrated to measure air pressure relative to sea level atmospheric pressure. Therefore, if the device is taken to a different altitude or location, its readings will not change. More about: Diaphragm pressure gauge working principle.

(3). Vacuum pressure is a measure of the negative difference between the gas pressure at a given location and the atmospheric pressure.

(4). Absolute air pressure is measured from zero or perfect vacuum (0 PSI). Again, unlike gauge pressure, this is not affected by the conditions surrounding the device. These conditions will vary with altitude and other factors.

(5). Differential pressure is the difference between two gas pressures. For example, the pressure difference in two gas hoses connected to the sensor. As with gauge pressure, a sensor may be able to measure changes in air pressure in either direction (i.e. positive or negative).

In addition to different types of measurements, some barometric pressure sensors are also designed to measure rapid pressure changes in dynamic environments. For example combustion pressure in engine cylinders or gas turbines.

Extended Reading: 4-20ma pressure transducer wiring diagram

Oxygen (O2) Pressure Measurement

Oxygen plays an important role in the smelting process, chemical industry, national defense industry, and medical care. However, the production and use of oxygen is extremely prone to combustion and explosion.

According to the mechanism of combustion and explosion “three elements” (combustibles, oxidants, excitation energy). The stronger, the more dangerous. Potential excitation energy sources for combustion or explosion are generally in the following ways: friction, compression heat, impact force, electric arc, resonance, etc.

For oxygen pressure measurement, a clean pressure sensor and a transmitter filled with inert oil is a safer choice. The risk of financial and time loss due to maintenance or faulty replacement is greatly reduced.

During the construction of industrial oxygen pipelines, multi-channel cleaning processes such as rust removal, scrubbing, sandblasting, blowing, degreasing, pickling, etc. should be carried out to remove oil and impurities in the pipelines so that they can meet the conditions for transporting oxygen media. And in accordance with relevant standards Check and accept. It can be used only after passing the test.

Extended reading: High accuracy pressure transducers

Featured Oxygen Sensors and Transducers

For oxygen pressure measurement, choosing a clean instrument filled with inert oil not only improves the safety level, but also greatly reduces the risk of economic and time loss caused by maintenance or failure replacement.

The pressure sensor for oxygen measurement supplied by Sino-Inst is required for the application of oxygen pressure measurement. The sensor product is filled with Fluorolube® oil. At the same time, oil-free technology is used for production. Finally, the sensor and transmitter are cleaned and packaged according to the oxygen level cleaning process.

The above sensors can be used in hazardous locations, including explosion-proof, intrinsically safe products. And it can be used in the occasions involving oxygen pressure measurement such as factories and hospitals.

The special pressure sensor for oxygen measurement must be cleaned strictly by oxygen grade cleaning process. Ensure that the sensor is clean and free of oil, corrosion, scaling, particles and other impurities. During the oxygen pressure measurement process, the potential risk of oxygen combustion or explosion caused by sensor oil pollution is completely solved.

Oxygen grade cleaning operations must be carried out in a dust-free and clean environment. To be operated by trained and qualified professionals. Use a special cleaning agent to clean the sensor and its accessories. Cleaning needs to go through multiple processes such as soaking, wiping, scrubbing, rinsing, drying, and sealing packaging. At the same time, during the cleaning process, special inspection equipment and precision instruments are used to conduct qualitative and quantitative inspections of the oil on the surface of the sensor. Make sure the sensor is clean.

Sino-Inst has an oxygen level cleaning platform, perfect cleaning process and quality control process. It cleans and seals the pressure sensor and pressure transmitter for measuring oxygen and high cleanliness.

Extended Reading: strain gauge pressure transducer

Hydrogen (H2) Pressure Measurement

Hydrogen (H2) is an extremely flammable, colorless, and odorless gas at normal temperature and pressure. Hydrogen has strong reducing properties and is a common industrial gas. It has a large number of applications in chemical, electronic, automotive, aerospace and other industries.

Hydrogen is easy to diffuse rapidly. When the ratio of hydrogen mixed with air exceeds 4%, it will become a combustible gas. Therefore, strict process and process control are required in the process of production, storage and transportation.

Since the hydrogen atom is very small, it will diffuse through the lattice of the diaphragm (usually stainless steel), thereby penetrating into the cavity filled with silicone oil. After long-term use, the infiltrated gas can damage the sensor.

Although gold is less permeable than stainless steel, gold-plated diaphragms are an effective way to prevent hydrogen permeation.

Extended Reading: Smart pressure transmitter working principle

Featured Hydrogen Pressure Sensors and Transducers

The pressure sensor dedicated to hydrogen measurement has many advantages in the pressure monitoring application of hydrogen production and purification equipment, hydrogen storage and transportation equipment.

In the process of measuring hydrogen pressure with a piezoresistive isolated pressure sensor. Since the atoms of hydrogen are very small, they will diffuse through the lattice of the diaphragm (usually stainless steel), thereby penetrating into the cavity of the sensor filled with silicone oil. Over time, the permeated gas can seriously affect the performance of the sensor. Effectively prevent the occurrence of “hydrogen embrittlement” and “hydrogen permeation”.

- Measuring range: -100kPa…0kPa~35kPa…20MPa

- Isolated structure, suitable for the measurement of hydrogen medium;

- Pure flat membrane structure, using no dead angle full welding technology, the minimum thickness of gold plating layer is greater than 2μm;

- The purity of gold plating on the surface reaches 99.8%;

The problem of hydrogen storage and transportation is an important factor affecting the cost of hydrogen. Pipeline hydrogen transportation has low cost and low energy consumption. It can realize continuous, large-scale and long-distance transportation of hydrogen energy. It is an important breakthrough direction for hydrogen storage and transportation problems.

It can be applied to hydrogen transportation scenarios such as hydrogen transportation vehicles. At the same time, it is also very suitable for pressure measurement of hydrogen storage cylinders and tank trucks and other gas and liquid hydrogen in hydrogen transportation.

Read more about: Types of biogas flow meters

Chlorine (CL2) Pressure Measurement

Chlorine is a simple substance formed by chlorine, with the chemical formula Cl2. It is yellow-green under normal temperature and pressure. It is a highly toxic gas with a strong pungent smell. It is suffocating and has a higher density than air.

Melting point -101.00°C, boiling point -34°C. Soluble in water and alkali solution, easily soluble in organic solvents (such as carbon tetrachloride), hardly soluble in saturated saline. It is easy to compress and can be liquefied into yellow-green oily liquid chlorine.

Generally, steel, iron, copper, nickel, etc. are resistant to dry chlorine, but once chlorine gas is mixed with a small amount of water, it will generate hypochlorous acid and hydrochloric acid, which are highly corrosive to most metals.

Therefore, pressure sensors and transmitters used for chlorine pressure measurement must use special corrosion-resistant housing and diaphragm materials to ensure reliable and accurate measurement.

More about: The Difference Between Absolute And Gauge Pressure

Featured Chlorine Pressure Sensors and Transducers

There are 2 types of chlorine pressure transmitters that are common:

- Dry chlorine. Pure chlorine gas is non-corrosive. It can be said that it is economical and affordable to use ordinary pressure gauges to measure pressure.

- Moist chlorine. If chlorine contains water, chlorine and water will react chemically to synthesize HCL and chloride ions. We all know that chloride ions are highly corrosive, and a special pressure transmitter must be used to measure pressure in order to resist the corrosion of chloride ions.

The pressure gauge used to measure chlorine gas containing moisture is a dedicated diaphragm pressure transmitter. The material of the instrument diaphragm isolator is 316L+F4, and the isolation diaphragm is 316L+F4. This diaphragm pressure transmitter is the most cost-effective. Isolation diaphragm can also choose Ta+F4. The price of this chlorine pressure transmitter is relatively high.

According to the actual situation of the user, select the chlorine gas pressure transmitter suitable for the actual situation on site.

Extended Reading: MEMS Pressure Sensors

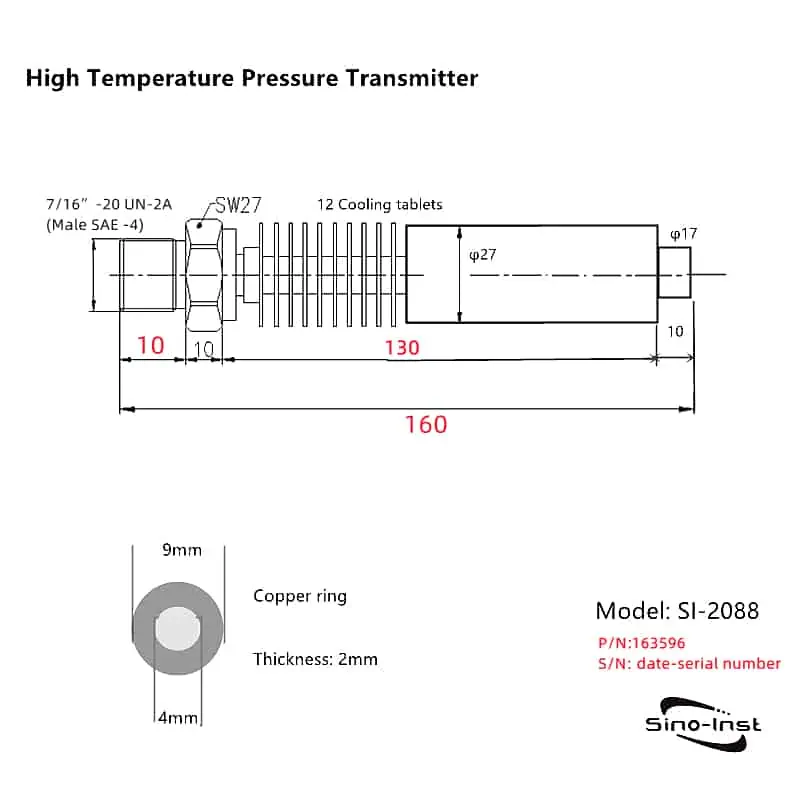

High Temperature Gas Pressure Sensors

High Temperature Gas Pressure Sensor for pressure measurement of high temperature gas. High temperature up to 800 ℃.

High Temperature Pressure Sensor with high temperature resistant pressure core or sapphire core as pressure measurement material. After high reliability amplifier circuit and precise temperature compensation. The absolute or gauge pressure of the measured medium is converted into standard electrical signals such as 4 ~ 20mA, 0 ~ 5VDC, 0 ~ 10VDC. It is also widely used in industry. Collect pressure signals at the points of some high-temperature steam and fluid pipes.

- Range: -100KPa ~ 0 ~ 100MPa optional

- Accuracy: ± 0.5% FS (composite error including non-linear repeatability hysteresis)

- Output signal: 4 ~ 20mADC (two-wire system), 0 ~ 10mADC, 0 ~ 20mADC, 0.5 ~ 4.5VDC, 0 ~ 5VDC, 1 ~ 5VDC, 0 ~ 10VDC (three wire system)

- Power supply voltage: 5 ~ 40VDC (two-wire system), 15 ~ 40VDC (three-wire system)

- Medium temperature: -40 ℃ ~ 200 ℃ -40 ℃ ~ 400 ℃ -40 ℃ ~ 600 ℃ -40 ℃ ~ 800 ℃

- Ambient temperature: -30 ℃ ~ 105 ℃

- Pressure connection: M20 * 1.5 M22 * 1.5 M16 * 1.5 M11 * 1 NPT1 / 4 NTP1 / 2 NTP3 / 8 G1 / 8 G1 / 2 G1 / 4 G3 / 8,1 / 2-20UNF, etc. Other threads can be according to customer requirements design

Frequently asked questions

If you cannot find an answer to your question in our Industrial Gas Pressure Sensors and Transducers, you can always contact us and we will be with you shortly.

More Gas Measurement Solutions

Sino-Inst is a manufacturer of Industrial Gas Pressure Sensors and Transducers. We offer more than 50 types of Gas Pressure Sensors.

Industrial Gas Pressure Sensors and Transducers are used in hydraulic and pneumatic control systems, thermoelectric units, constant pressure water supply systems, power station operation inspections, petrochemical, environmental protection, air compression, locomotive braking systems, light industry, mechanical metallurgy, building automation, and other automation And testing systems, industrial process testing and control, laboratory pressure calibration, etc.

Sino-Inst’s entire team is well trained, so we can ensure that each customer’s needs are met. If you need any help with your product requirements, whether it is Industrial Gas Pressure Sensors and Transducers, level sensors, or other equipment, please give us a call.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.