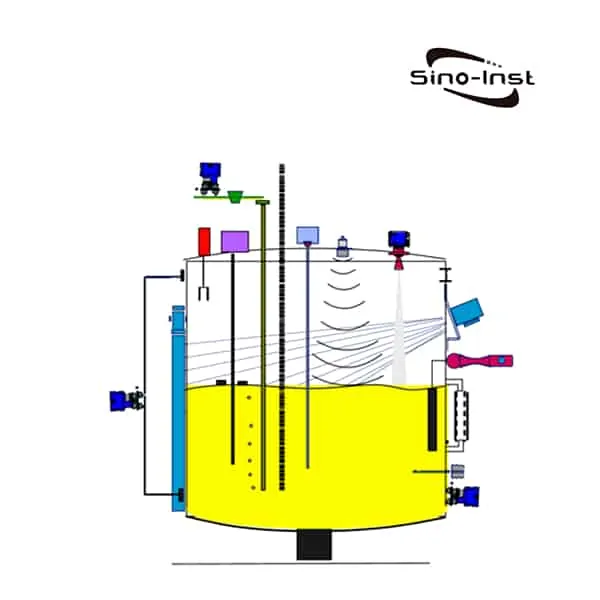

Tank level indicators are level gauges that can measure and display the level of industrial liquid storage tanks. Liquid level refers to the level of liquid in a sealed container (for example oil/fuel tank) or an open container (water tank).

In industrial production, it is often necessary to know the liquid level in the storage tank. The liquid level sensor converts the liquid level signal in the container into a switch signal or a voltage and current signal. Then through the external circuit, the measurer can intuitively know the liquid level in the container. There are many types of Liquid level indicators. By reading this article, you will know what kind of level indicators is best for your tank.

Sino-Inst offers a variety of Tank level indicators for level measurement. If you have any questions, please contact our sales engineers.

Featured Tank Level Indicators and Gauges

Read more about: 7 Level Senors for Tank Level Measurement

Tank level indicators for common tanks

Water tank level indicator

Water tank level monitoring is the most common application of Tank level indicators.

Common water, purified water, application water, etc. Less impurities. If the tank is not sealed. It can be applied to the hydrostatic input level gauge. The lowest cost. The easiest to use.

Of course, if the tank is sealed. Or there are impurities in the water. A diaphragm seal differential pressure level transmitter can be used.

According to your actual measurement installation situation, you can also choose other applicable Tank level indicators and Tank Level Gauges.

Read more about: Water Tank Level Sensors for Level monitoring and Auto-control

Propane tank level indicator

Propane is a gas that can be liquefied. Chemical formula CHCHCH, colorless, liquefiable gas. Slightly soluble in water, soluble in ethanol and ether.

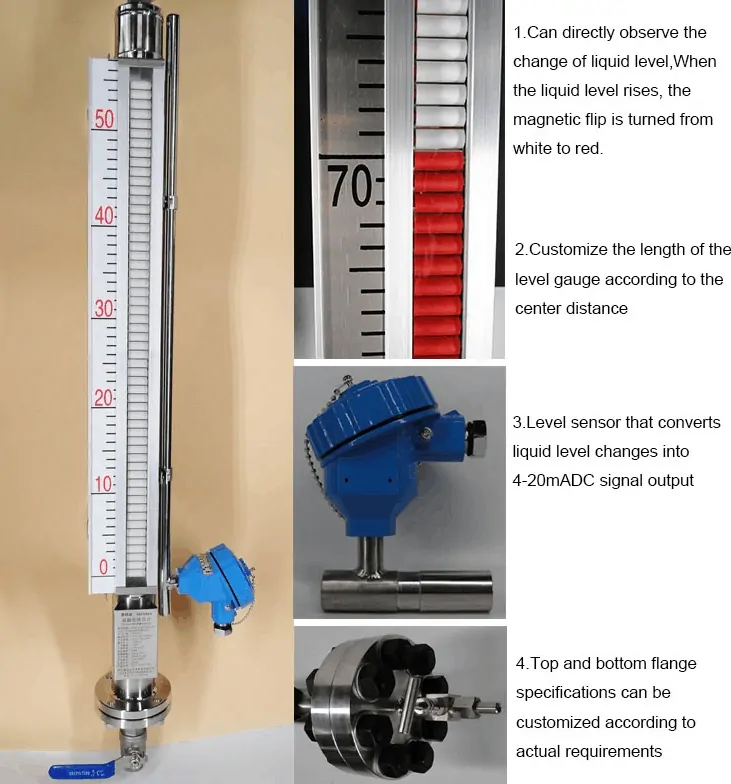

Common Industrial Propane Tank Level Indicators for Industrial Tank Level Measurement include: radar level sensor; magnetostrictive level sensor; float level gauge; magnetic flap level gauge; ultrasonic level gauge.

What kind of level gauge is used for Industrial propane level measurement?

Please refer to:

Fuel & oil tank level indicator

Measure the level of oil storage tanks. We recommend the use of a magnetostrictive level gauge or an externally attached ultrasonic level sensor.

Advantages of magnetostrictive level gauge for measuring oil tank level:

- The magnetostrictive liquid level gauge can simultaneously measure multiple parameters such as liquid level, interface level, and temperature.

- The measurement range is large, and the maximum measurement range can be 20m.

- Measurement grade products, high measurement accuracy, can reach up to ±1mm.

- Using pure electronic technology to measure, so there is no wear, safe and reliable, and long service life

- The measurement accuracy is not affected by factors such as the shape of the container and the steam in the container.

- No need for regular calibration, easy installation and maintenance without tank cleaning.

- Multiple signal output, easy to realize the monitoring function of the system.

- The product design meets the requirements of explosion-proof standards, and achieves explosion-proof and intrinsically safe certification.

Extended reading: Capacitance level sensor advantages and disadvantages

Advantages of Ultrasonic Tank Level Sensor-External Mounted

- Non-contact measurement function ——– Ultrasonic sensor probe is external. No need to open a hole in the container to be tested.

- Auto-calibration function——–With self-calibration function. It overcomes the problem of reduced accuracy after long-term use of traditional liquid level gauges.

- Infrared online debugging function——–Applicable to occasions where it is not suitable to open the cover for testing in dangerous situations. At the same time, it reduces the difficulty of debugging.

- Self-diagnosis function——–It has its own working status diagnosis function. It also has hardware diagnosis function. It enhances the reliability and stability of the level gauge.

- One-key recovery function——–When the external measuring level gauge works abnormally, it can be restored to the normal state with one key through the debugger.

- Local display and remote transmission function——–The level gauge can not only display the level value on the spot in time. But also remotely transmit it to the control room through the signal line.

Extended reading: GWR Corrosive Liquid Chemical Level Sensor

large water tank level indicator

In industrial production, water tanks are widely used. In many production equipment, the measurement and control of the water tank level is directly related to the normal operation of the process production process. At present, there are many methods for measuring and controlling the liquid level of the water tank, each with its own strengths.

- If the site is an open tank, it needs to have a remote transmission function. If there is no requirement for a scale, it is recommended to use a submersible level gauge. The cost is low. The principle of cable-type diffusion silicon. Simple and easy to use. , 24V power supply.

- If the site needs to have a scale and a remote transmission function. That is to use a magnetic float level gauge with a remote transmission function. That is, the liquid level can be displayed on site. And the liquid level can be transmitted to the control room or PLC for display.

- Pressure type liquid level transmitter. This is also the simplest principle of using pressure to display the liquid level height. It is installed at the bottom of the side-loading tank. 24V power supply.

- Ultrasonic level gauge. When the ultrasonic level gauge is used, there should be no foam on site. Otherwise, the display will be inaccurate. The clean water pool can be used.

These are all very simple level gauges. But in fact, they still need to be selected according to the working conditions. Before purchasing, it is best to ask the manufacturer.

Read more about: Types of water level controller

You may like:

Extended reading: Types of Fuel-Diesel Level Sensors

If you need to measure the tank level. But you still don’t know how to choose suitable Tank level indicators and Tank Level Gauges, please contact Sino-Inst sales engineer.

Sino-Inst offers over 30 Tank level indicators and Tank Level Gauges for level measurement. About 50% of these are Radar level meters, 40% is the magnetic level sensor.

A wide variety of Tank level indicators and Tank Level Gauges for level measurement options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Tank Level measurement instrumentation, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.