What is a Level Transmitter?

A level transmitter is a type of instrument used to measure the level of liquids, slurries, and granular materials in a container, such as a tank or a silo. These devices are essential in various industrial and commercial applications for monitoring and controlling the levels of materials.

Level Transmitters, also called level gauges. Different types of Level transmitters provide contact and non-contact level measurement.

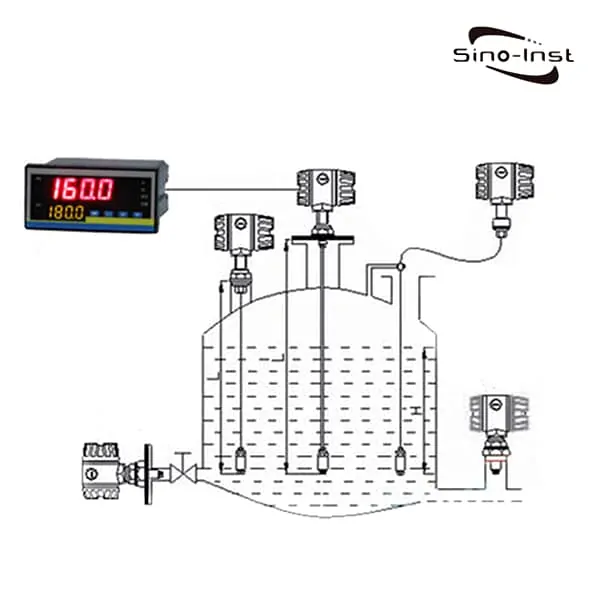

level measurement instruments For industrial process control

Level measurement instruments are used in industrial process control to accurately measure the liquid level in tanks, containers or silos. This has significant implications for industrial processes:

Process efficiency and optimization: By continuously monitoring liquid levels, the amount of material entering or leaving the process can be precisely controlled. Essential for maintaining optimal process conditions, increasing efficiency and ensuring the quality of the final product.

Ensure safety: In industries where spills or leaks could cause safety hazards or environmental contamination, such as the chemical or oil and gas industries, ensuring that liquids are controlled within safe levels reduces the risk of spills and related hazards.

Inventory Management: Accurate liquid level measurement helps in better liquid inventory management. It accurately tracks material usage, helping with demand forecasting, procurement planning and cost management.

Automatic control system integration: The liquid level transmitter can be integrated into the automatic control system. They provide real-time data that can be used to automatically adjust valves, pumps and other control components.

Data for process analysis and improvement: The data collected by the level gauge can be used for process analysis and improvement.

Customization and Versatility: Liquid level gauges are available in a variety of designs and operating principles, such as ultrasonic, radar, and capacitive, making them suitable for a variety of liquids with different characteristics such as viscosity, temperature, and chemical composition. This versatility ensures they can be customized to meet specific process requirements.

Types of Level Transmitters:

How many types of level transmitters are there? There are 7 main types of level transmitters that Sino-Instrument offers. Each type of transmitter works in a different way, and makes it useful for different types of processes.

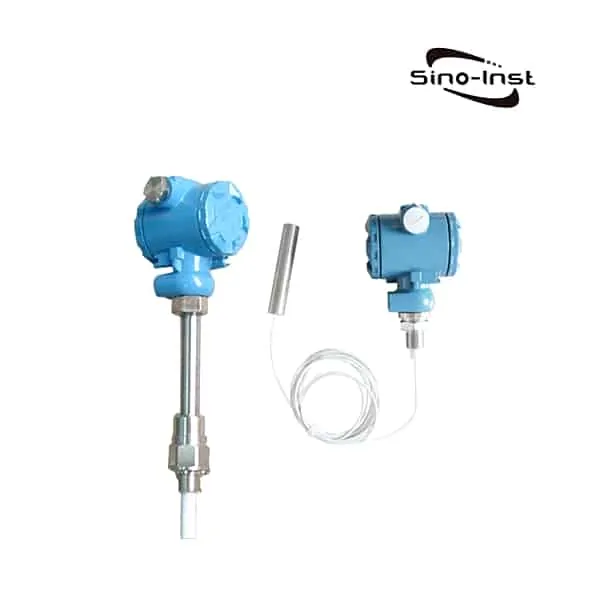

Magnetostrictive Level Transmitters

The magnetostrictive liquid level meter/transmitter is a highly precise magnetic liquid level sensor that can continuously measure liquid level and boundary level, and provides on-site display and analog signal output.

The structural part of the magnetostrictive level gauge is composed of stainless steel tube (measuring rod), magnetostrictive wire (waveguide wire), movable float (with permanent magnet inside) and other parts.

When the liquid level gauge is working, the circuit part of the liquid level gauge will excite a pulse current on the waveguide wire. When the current propagates along the waveguide wire, a pulse current magnetic field will be generated around the waveguide wire.

There is a float outside the liquid level measuring rod, which can move up and down along the measuring rod as the liquid level changes. There is a set of permanent magnetic rings inside the float. When the pulsed current magnetic field meets the magnetic ring magnetic field generated by the float, the magnetic field around the float changes so that the waveguide wire made of magnetostrictive material generates a torsional wave pulse at the position of the float. This pulse moves along a fixed speed at a fixed speed. The waveguide wire is transmitted back and detected by the detection mechanism.

By measuring the time difference between the pulse current and the torsional wave, the position of the float, that is, the position of the liquid level, can be accurately determined.

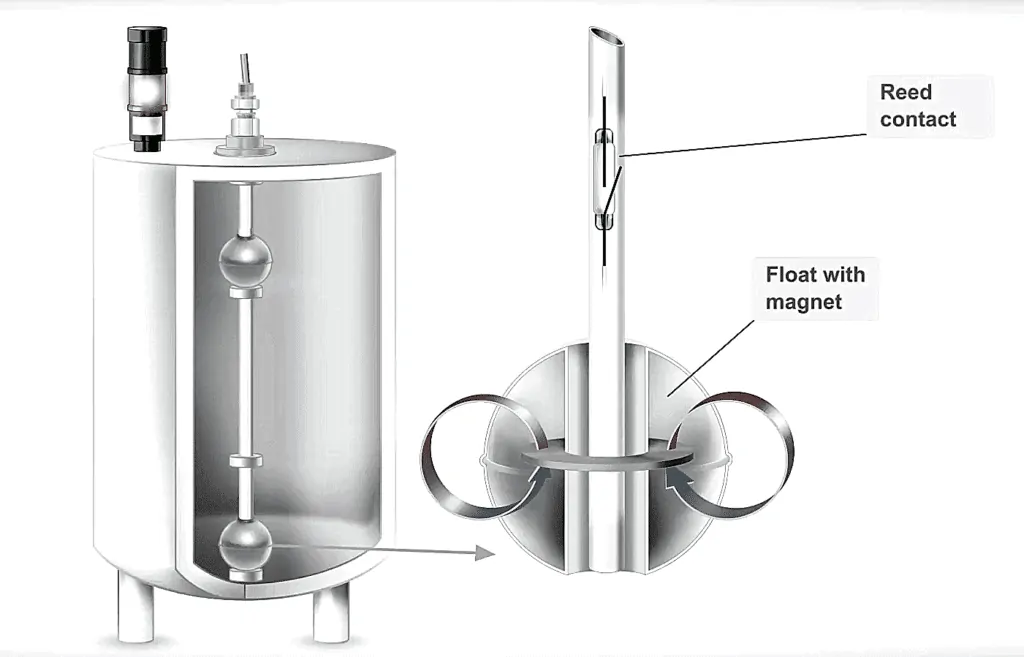

Magnetic Float Level Sensors

Magnetic Float level sensors are continuous level sensors featuring a magnetic float that rises and falls as liquid levels change. The movement of the float creates a magnetic field that actuates a hermetically sealed reed switch located in the stem of the level sensor, triggering the switch to open or close.

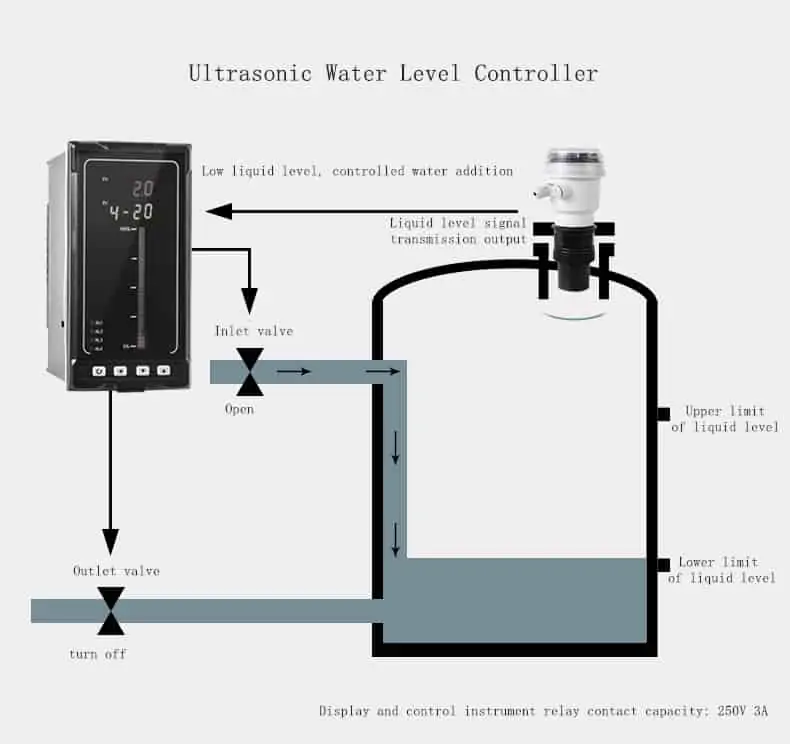

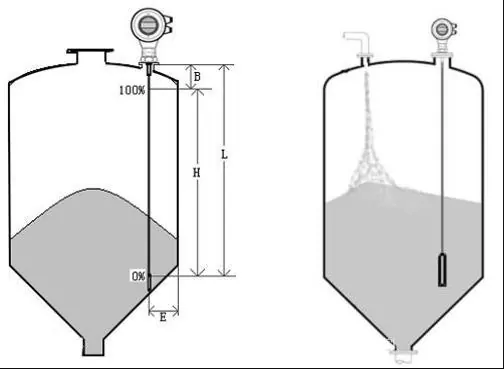

Ultrasonic Level Transmitters

Ultrasonic Level Indicator, also called Ultrasonic level sensor, or ultrasonic level transmitter. In this type of transmitter, an ultrasonic transducer is mounted at, or near the top of a container containing liquid. The transducer sends out an ultrasonic pulse. The pulse hits the surface of the liquid, and gets reflected. The sensor then calculates the fill level based on the time between the transmitted and received signal.

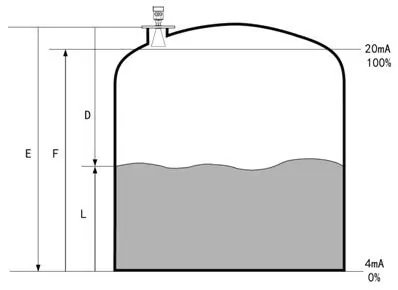

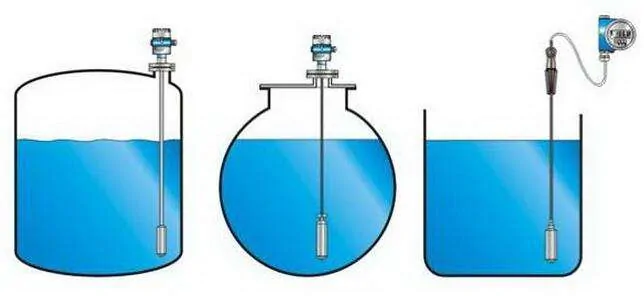

Hydrostatic Level Transmitters

Hydrostatic level transmitters, also called submersible level transmitter, or pressure level transmitters. For Hydrostatic level measurement, Continuous level measurement in liquid applications with pressure sensors. These transmitters help in determining fluid level of a container. By measuring the pressure of resting body of the fluid within it.

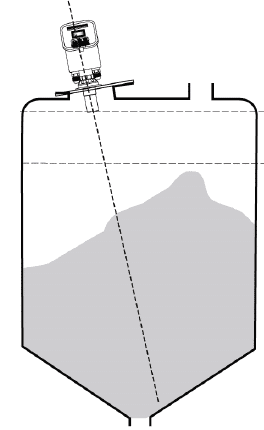

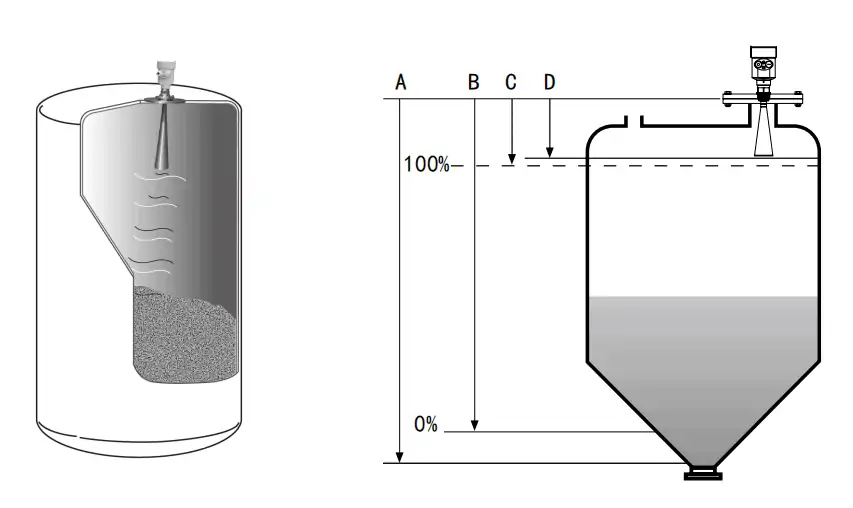

Radar Level Transmitters

Radar level transmitter, also called Radar level gauge. Non-contact Continuous level measurement in liquids and solids with free space radar sensors. Non-contacting radar, based on microwave technology, detects only surfaces that reflect energy. These transmitters work on the principle of a radar by using radio wave emissions. Mounted at the top of a tank filled with a liquid. The transmitter sends a radar signal into the liquid, and receives a reflection of the signal. The transmitters then analyze the current fill level of the tank based on the time taken by the transmitted signal to return.

Guided Wave Radar (GWR) Level Transmitters

Guided Wave Radar (GWR) Level Transmitters, also called wave guided radar level transmitter. Using guided wave radar technology, GWR level transmitters have no moving parts. They can measure both level and the interface between two media. Continuous level measurement in liquids and solids with guided wave radar sensors. These transmitters work by sending a microwave pulse through a sensor cable or rod. The signal hits the surface of the liquid, and travels back to the sensor, and then to the transmitter housing. Based on the time taken by the signal to travel down the sensor and back up again. The electronics integrated in the transmitter housing determine the filling level.

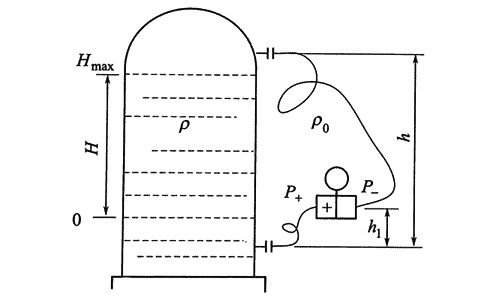

Differential pressure (DP)level transmitter

Differential Pressure (DP) Level Measurement uses pressure readings and specific gravity to output level. DP Level is a common measurement technique that is used in a wide variety of applications. Solutions include standard transmitter connections and integrated transmitters with direct or remote mount seals that can be configured in tuned, balanced, and electronic systems. Additional Wireless options are also available.

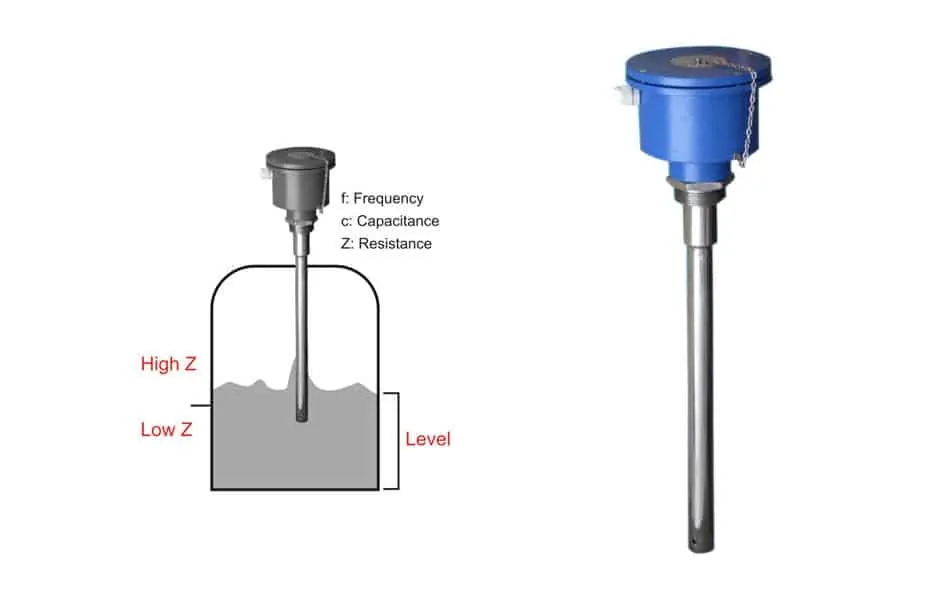

RF Capacitance Level Transmitter

Capacitance level detectors, also known as Capacitance level transmitter. RF Capacitance Level Transmitter offers continuous and point level detection. In liquids and solids with capacitance probes. These transmitters use liquid stored in a tank or container as a dielectric medium between two or more electrodes. The energy capacity of the capacitor circuit increases when there is more liquid, and decreases if there is less liquid. Measuring the variations in the capacitance value, capacitance level transmitters calculate level of the tank.

Our Benefits

- One-stop level measurement solution for all your level transmitters requirements

- Small Order Quantity OEM

- Manufacturer price

- Fast and effective

Typical Applications

Industries Served:

- Oil and Gas

- Petrochemical

- Chemical

- Power Generation

- Water and wastewater treatment

- Pulp and Paper

- Biotech

- Marine

Applications:

- Position Sensing

- Sanitary Service

- Valve Positioning

- Inventory Control

- Corrosive Process

- Underground Tanks

- Primary Level/Interface

- Process Temperature and Leve

What is level transmitter working principle?

Let’s take a closer look at how different types of level transmitters work.

Learn More About Level Transmitters

If you cannot find an answer to your question in our Level Transmitters, you can always contact us and we will be with you shortly.

More Level Measurement Solutions

- Quickly Set Level Monitoring System for Industrial Holding Tanks

- How to check Level in Underground Tanks? What Tank Level Indicators to Choose?

- Enhancing Marine Tank Monitoring with Advanced Marine Water Tank Level Sensors

- Shopping the Right High Temperature Level Sensor: 80℃~1000℃

- What Is the Ultrasonic CO2 Level Indicator? CO2 Bottle Level Measuring Device

- Radar Level Gauge – Everything You Should Know and Selection List

- Innovative Methods for Fluid Level Measurement

- Choose the Right Submersible Water Level Sensor for Your Application

- New Choice for Heating Oil Tank Level Sensor

- What Is Capacitive Level Sensor?

- How to Choose the Right Diesel Fuel Level Sensor ?

- Submersible Level Transducer – First Choice for Water Level

- Shop Radar Level Sensors for Solids: 5 Must-Know Factors

- What Is Radar Level Transmitter Frequency Range? What Is the Effect?

- Case Study: Automatic Sludge Blanket Level Detector

- Ultrasonic Level Sensor for Diesel Tanks | 5~150cm,0-30m

- Cryogenic Level Sensor for Liquid Nitrogen Tank Level Indicator

- Influence of Dielectric Constant on Liquid Level Measurement | Radar-Guided Wave Radar Level Meter

- Liquid Volume Sensor? Monitors Liquid Volume Solutions

- Underwater Pressure Transducer|IP68-for Underwater Pressure or Level Measurement

- Water Level Transducers – Detailed Guide

- Explosion Proof Ultrasonic Level Sensor| Hazardous Area-Non Contact

- New Trend of Transformer Oil Level Indicator

- External Tank Level Indicator

- 80GHZ Radar Level Transmitter

- Material Level Indicators

- The Secret of Water Level Control

- Wastewater Level Sensor for Septic Tank-Sewage Holding Tank

- Water Level Monitoring Sensor/System for Sewage-Wastewater

- Tank Level Gauges & Indicators

- External Ultrasonic Tank Level Sensor

- Ultrasonic Liquid Level Measurement

- The Secret of Ultrasonic Level Measurement

- Guide to Ultrasonic Level Transmitters-for Continuous Non Contact Level Measurement of Liquid & Solids.

Level Transmitter Price

When choosing a level transmitter, we must first understand what our measurement conditions are like.

Such as:

- What is the measurement range?

- What is the measurement medium?

- What is the measurement pressure?

- What is the measurement temperature?

- Does it need explosion protection?

- Are there any material requirements?

- Do you need a local display?

- What is the installation method and installation size?

- Signal output requirements?

Then we choose which type of level transmitter is suitable for our level measurement. If you have difficulty in product selection, please feel free to contact us!

Based on the product selection, we can determine the price of the level transmitter. Sino-Instrument is a manufacturer of level transmitters, so we offer the best price.

For example: The reference price of a differential pressure level transmitter is around USD 400.

Sino-Inst, is a manufacturer of Level Transmitters. We provide more than 50 Level Transmitters. Including commonly used Level Transmitters. There are: input liquid level transmitter, flange capacitive liquid level transmitter, ultrasonic Level Transmitters, radar Level Transmitters, inductive Level Transmitters, float type liquid level transmitter, magnetostrictive liquid level transmitter Wait.

Sino-Inst’s Level Transmitters are the most commonly used sensors in industrial applications. Widely used in water conservancy and hydropower, railway transportation, intelligent building, production control, aerospace, military industry, petrochemical industry, oil pipeline well, electric , pipeline and other industries.

Sino-Inst’s entire team is well trained, so we can ensure that each customer’s needs are met. If you need any help with your product requirements, whether it is a pressure sensor, level sensors, or other equipment, please give us a call.

Request a Quote