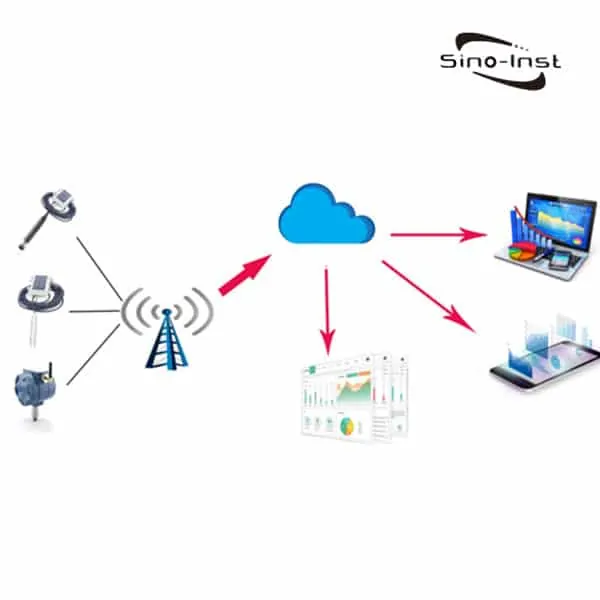

Wireless pressure sensors are a game changer for many industries. No longer do you have to worry about wiring costs or maintenance. Our wireless battery powered pressure monitoring system offers long range connectivity via Bluetooth, or GPRS-NB-iot-LORA. It allows you to keep an eye on water pressure and offers differential pressure monitoring. With the help of our wireless pressure sensors, you’ll be able to keep a close eye on your operations without the need for a controller or indicator.

Sino-Inst offers a variety of Wireless Pressure Sensors for industrial pressure measurement. If you have any questions, please contact our sales engineers.

Featured Wireless Pressure Sensors

Features of Wireless Pressure Sensors

- Ultra-low power consumption design. 60UA in sleep mode (3.6VDC battery power supply)

- NB-iot Narrowband Internet of Things. Supporting our company’s Internet of Things cloud acquisition and monitoring platform.

- Online monitoring. PC and mobile data applications. Real-time/historical/alarm data query.

- On-site low-power five-digit display header. Continuous display and trigger display can be divided (optional)

- Remote configuration: Remote configuration of parameters such as acquisition frequency/sending frequency/upper and lower alarm limits.

- Data communication protocol MODBUS TCP. .

- Dual power supply. The battery is powered by 3.6VDC/7.2 VDC lithium sub-battery. The battery life depends on the frequency cycle of the collected data. Generally it can be used for about 2-5 years. External power supply 5-30VDC.

- High-precision 24-bit ADC collects and digitizes sensor signals.

- Enhanced EMC anti-interference design. It is suitable for various industrial environments with harsh electromagnetic environment.

- Abnormal alarm: abnormal alarm of overvoltage and undervoltage/low battery in the pipeline network

- 24hX365 online monitoring. The data server records data for several years.

- Open cloud platform API interface/MODBUS-TCP interface. Seamlessly connect with user’s industrial configuration system, customized software and special platform.

- The installation location of NB-iot IoT products must have NB-iot base station signal. Special IoT card. Low cost and low traffic, annual use.

Low power-battery powered

The low-power wireless pressure transmitter adopts advanced micro-power devices and perfect software management technology. Ensure the real-time performance of data monitoring and instrument status. Built-in large-capacity high-performance lithium battery, which can work continuously for 2-5 years.

Realize remote real-time monitoring, wireless transmission, no need for on-site wiring, saving manpower and construction costs.

The instrument is advanced in design, easy to install and use, and is an ideal upgrade product for traditional pressure transmitters.

Application of wireless pressure sensor

Wireless pressure sensors are mainly used in the following four aspects:

- In the power industry. Wireless pressure sensors can be used in data transmission fields such as reactive power compensation, power distribution monitoring, meter collection, and street lamp monitoring.

- In the water application industry. Water meter collection, remote monitoring of water resources management, wireless communication of waterway network monitoring.

- In the field of environmental protection. Online monitoring system of pollution sources such as CEMS, water quality online monitoring, etc.

- In the field of equipment maintenance. Such as elevator monitoring, air conditioning monitoring, etc.. Pressure sensors can be quickly embedded in the user’s monitoring instruments to complete the device monitoring GPRS remote transmission application.

Read more about: What is industrial pressure transmitter?

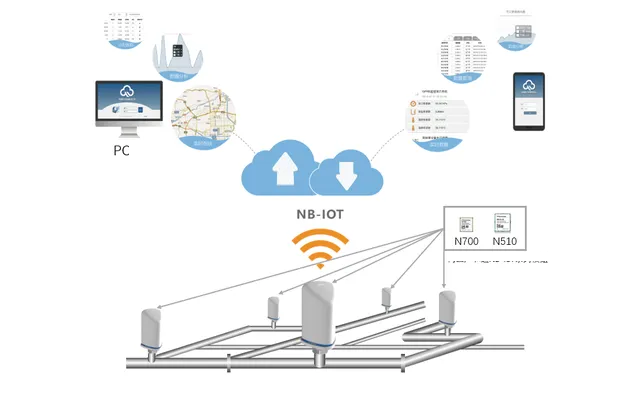

NB-IoT Wireless Pressure Transmitter Networking Solution

Petroleum pipelines have the characteristics of large diameter, high pressure and large transmission volume. In the process of oil and gas transportation, the pressure transmitter is used to effectively monitor the pressure of the oil pipeline. Further prevent the occurrence of oil and gas pipeline leakage accidents and ensure the safe operation of oil and gas pipelines.

Industry pain points:

- The energy transmission pipeline covers a wide area, and the pressure monitoring system based on the wired network is costly and difficult to deploy;

- The pressure transmitter is often placed under the ground along with the pipeline. Once installed, it is not easy to replace. A low-power wireless networking solution is required to extend battery life.

NB-IoT wireless pressure transmitter integrates pressure detection, data acquisition, NB-IoT wireless communication, battery self-power supply and other functions. Realize high-precision measurement, automatically set the collection frequency and reporting frequency. Use NB-IoT network to upload data.

Background staff can set alert values for pressure data. Once the warning value is reached, measures to automatically close the valve can be taken immediately. Send work orders to maintenance personnel for quick processing.

The NB-IoT network covers a wide range. Under the same frequency band, NB-IoT has a gain of 20dB compared with the existing network, which is equivalent to improving the coverage area by 100 times. At the same time, it meets the coverage depth of the underground pipe network to ensure that there are no blind spots in the network;

NB-IoT can support massive IoT terminal connections. Supports low latency sensitivity and ultra-low device power consumption. Terminal standby time can reach more than 10 years;

The wireless pressure transmitter can collect, display, measure, report and store metering data in real time. Synchronously upload to the management platform. Ensure that the background personnel can monitor the pipeline status in real time.

Wireless Level Sensor – LoRa

The Wireless Level Sensor upgrades the LoRa wireless transmission function based on the Hydrostatic Level transmitter. Measure water or oil level. This product adopts the LORA debugging method, which can greatly increase the communication distance. It can be widely used in the field of short-distance Internet of Things wireless communication in various occasions.

Read More about: Wireless Level Sensor – LoRa

Wireless pressure sensor system

The rapid development of wireless communication technology and computer technology has been applied to sensor technology. It makes wireless data collection of pressure sensors possible. Its unique performance is more advantageous than traditional pressure sensors. It can be used in areas where wiring and power supply are difficult, areas where people cannot reach. Such as high temperature, severe cold, high humidity areas, contaminated areas or areas where the environment is destroyed. And some temporary occasions. Realized the sensing system Remote testing. This is also an inevitable trend of testing in the information age.

System design

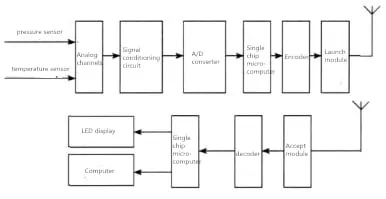

The pressure sensor wireless acquisition system designed in this paper is composed of the front-end sensor data acquisition transmitter part and the terminal data receiver part. Figure 1 shows the block diagram of the transmitter part (upper) and the receiver part (lower) of the sensor data collection.

The sensor data acquisition and transmission part is composed of a pressure sensor, a temperature sensor, a signal processing part, a microprocessor (generally a microcontroller) and a wireless transmission circuit.

Pressure and temperature sensors acquire pressure and temperature values of the surrounding environment.

The signal processing part includes the preceding channel, program-controlled amplifier and A/D converter. Its function is to extract and amplify the analog signal of the sensor under program control and perform analog/digital conversion.

The microprocessor is responsible for controlling the work of each part of the system and processing digital signals. The wireless transmission circuit is under the control of the microprocessor. The encoder encodes and processes the collected information data and transmits it with the transmission module.

The data receiving part is composed of wireless receiving circuit, microprocessor and display part.

Receive data from radio under the control of a microprocessor. After receiving a set of format data, the decoder in the receiving circuit decodes the format data. The current pressure information of the environment is obtained. Then the pressure information is displayed on the LED receiving panel.

Extended Reading: How does a MEMS pressure sensor work?

Pressure transducers for sale

Also called Hygienic pressure Transmitters, or tri clamp pressure transmitter. Sanitary pressure Transmitters is used to food &beverage or pharmaceutical application.

High-temperature pressure transmitters with a 4-20mA output.

which has a temperature capability of over 850 °C and is not pyroelectric.

Absolute pressure transmitter with 4-20mA output for measuring pressure with absolute type reference. Absolute pressure (AP) transmitter is a measure of the ideal (complete) vacuum pressure.

Hydrostatic pressure transmitter is used for fluid hydrostatic pressure measurement. With working static pressure up to 32Mpa, for liquid, gas or steam .

Digital Pressure Sensor is particularly suitable for use in computer control systems. RS485 half-duplex working mode.

OEM pressure sensors from Chinese manufacturer. Silicone filled. Protected by stainless steel diaphragm. Suitable for a variety of fluid media.

Flush membrane / diaphragm structure, anti-blocking design. Pressure measurement of viscous media.

Liquid pressure sensor is widely used for pressure measurement of various liquids. Like water or oils. IP68 waterproof.

High Temperature Pressure Sensor for pressure measurement of high temperature gas or liquid. Such as steam pressure. High temperature up to 800 ℃.

Silicon pressure sensor, also known as Diffused silicon pressure sensor. Silicon pressure sensors are low cost.

Combined pressure and temperature sensor for Simultaneous measurement of pressure and temperature.

Thermocouple types: J, K, E type or PT100 platinum resistance. Two outputs do not affect each other.

Ceramic pressure sensor is a pressure sensor refined from a thick ceramic base using a refined ceramic base. Cost-effective. Support OEM processing. 0-0.2MPa -…- 40MPa

More Applications and Markets of Wireless Pressure Sensors

Water Pressure Sensors for Measurement of Water Pressure

Underwater Pressure Transducer|IP68-for Underwater Pressure or Level Measurement

What is Static Water Pressure?

Water Pressure Transducers

Small Pressure Transducer/Sensor-Low Cost-High Performance

What’s the Difference Between a Pressure Transducer and a Pressure Switch?

Wireless pressure sensor manufacturer

In conclusion, wireless pressure sensors have revolutionized the way industries monitor pressure measurement. The wireless battery powered pressure monitoring system has eliminated wiring costs, improved safety, and reduced maintenance costs.

Our wireless pressure transmitters offer additional features and benefits when compared to traditional pressure transmitters. If you’re interested in learning more about our wireless pressure transmitters, contact us today.

Sino-Inst, as the manufacturer of wireless pressure sensors, offer you with the best price.

Sino-Inst offers 10 wireless pressure sensors products. These are wireless pressure sensors, wireless differential pressure transmitter, and wireless temperature transmitter.

A wide variety of wireless pressure sensors options are available to you, such as free samples, paid samples. Sino-Inst is wireless pressure transmitter manufacturer, located in China.

Wireless pressure sensor products are most popular in North America, Domestic Market, and South America. You can ensure product safety by selecting from certified suppliers, with ISO9001, and ISO14001 certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.