Radar Liquid Level Sensor is an instrument that measures the height of a liquid and converts it into an electrical signal. Using time-domain reflectometry (TDR) sensing technology, Radar Liquid Level Sensor emits and receives high-frequency radio waves (microwaves) to measure the distance to the surface of liquid-based substances. Different from the ultrasonic and guided wave radar transmitter. SIRD-902T Microwave Radar Liquid Level Sensor is a self-heating microwave level sensor. Low-temperature resistance, heat tracing type, non-icing, and anti-crystallization. Suitable for corrosive liquids, steam, and volatile liquids.

Features of SIRD-902T Microwave Radar Liquid Level Sensor

Specifications of SIRD-902T Microwave Radar Liquid Level Sensor

| Application: | Temperature, pressure, slightly corrosive liquid |

| Measuring Range: | 20 meters |

| Process Connection: | Thread, flange |

| Process Temperature: | -40~130℃(standard type) / -40~250℃(high temperature type) |

| Process Pressure: | -0.1~2.0MPa |

| Accuracy: | ±3mm |

| Protection Grade: | IP67 |

| Frequency Range: | 26GHz |

| Supply: | Two-wire system (DC24V) / Four-wire system (DC24V/AC220V) |

| Signal Output: | Exia ⅡC T6 Ga / Exd IIC T6 Gb |

| Outer Covering: | Aluminum Single Chamber / Aluminum Dual Chamber / Plastic / Stainless Steel Single Chamber |

| Explosion-proof Grade: | 4…20mA/HART (two-wire/four-wire) / RS485 Mod bus |

| Antenna Material | Stainless Steel / PTFE |

Radar Level Sensor Application

The measurable conditions of the 902T Radar Liquid Level Sensor are as follows:

- Application: corrosive liquid, steam, volatile liquid

- Measuring range: 20 meters

- Process connection: flange

- Medium temperature: -40~130℃ (standard type)/ -40~230℃ (high temperature type)

- Process pressure: -0.1~2.0MPa

Read more about List of Radar Level Sensors

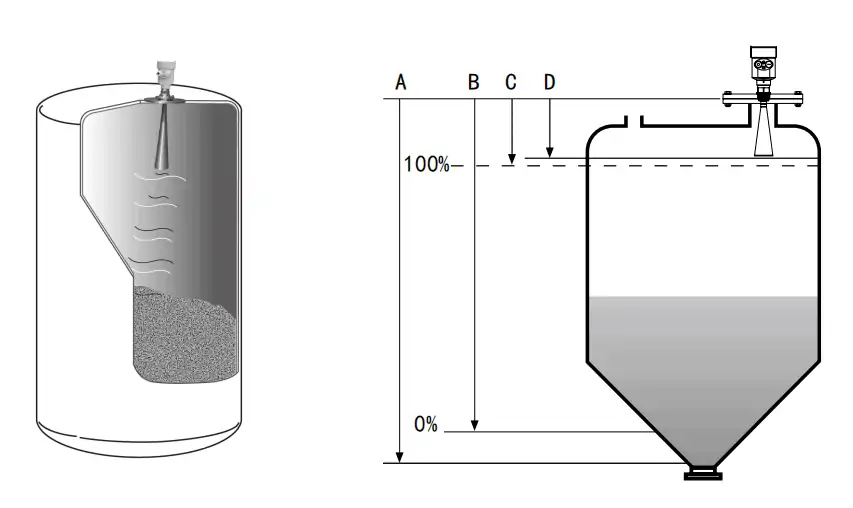

Radar Liquid Level Sensor Working Principle

The radar-level antenna emits narrow microwave pulses. Downward transmission via the antenna. After the microwave touches the surface of the measured medium, it is reflected back. It is received by the antenna system again and transmitted to the electronic circuit part to automatically convert it into a level signal.

Because microwaves travel so fast, the time it takes for electromagnetic waves to reach the target and return to the receiver by reflection is almost instantaneous.

A range setting

B Low adjustment

C high adjustment

D Blind zone range

The reference plane of the measurement is:

The bottom surface of the thread or the sealing surface of the flange

Note: When using radar level timing, make sure that the highest material level cannot enter the blind area of the measurement (the area shown in D in the figure).

Know more about Level measurement using radar technology

Radar Level Sensor Advantages and Disadvantages

Advantages of radar level measurement

Disadvantages of radar level measurement

Radar Level Sensor for Solids

Measuring medium: liquid and Solids

Measuring range: 0.1m~120m

Process connection: flange≥DN80

Process temperature: -40~200℃; -60~1200℃

Process pressure: -0.1~2.5MPa

Antenna size: 78mm lens antenna

Antenna material: PTFE/full filling

Measuring medium: solid

Measuring range: 0.3m~150m

Process connection: flange≥DN80

Process temperature: -40~110℃

Process pressure: -0.1~0.3MPa

Antenna size: 78mm lens antenna + purging (or without purging)

Antenna material: PTFE

Application: solid materials, strong dust, easy to crystallize, condensation occasions

Measuring range: 70 meters

Process connection: universal flange

Process temperature: -40~130℃ (standard type) / -40~250℃ (high temperature type)

Process pressure: -0.1~4.0 MPa (flat flange) -0.1~0.3 MPa (universal flange)

Accuracy: ±15mm

Protection level: IP67

Application: solid materials, strong dust, easy to crystallize, condensation occasions

Measuring range: 80 meters

Process connection: threaded, universal flange

Process temperature: -40~130℃ (standard type) / -40~250℃ (high temperature type)

Process pressure: -0.1~0.3MPa

Accuracy: ±15mm

Protection level: IP67

Application: solid particles, powder

Measuring range: liquid 35 meters / solid block 20 meters / solid powder 15 meters

Process connection: thread, flange

Process temperature: -40~130℃ (standard type) / -40~250℃ (high temperature type)

Process pressure: -0.1~4.0 MPa (flat flange) -0.1~0.3 MPa (universal flange)

Accuracy: ±15mm

Protection level: IP67

Applicable medium: solid particles or blocks, not suitable for solid powder

Application: Lime block measurement; raw coal measurement

Explosion-proof certification: Exia IIC T6 Ga/ Exd IIC T6 Gb

Measuring range: 35m

Antenna: Horn antenna

Frequency: 6 GHz

Process temperature: -40~130℃(standard type)/-40~250℃(high-temperature type)

Applicable medium: solid, especially medium measurement in a high-temperature environment

Application: Blast furnace level measurement

Explosion-proof certification: Exia IIC T6 Ga/Exd IIC T6 Gb

Measuring range: 15m

Antenna: Horn antenna

Frequency: 6 GHz

Process temperature: (-40~400)℃

Radar Level Sensor Price

The price of the radar level sensor is related to the medium, installation method, and pressure level.

- The medium is divided into ordinary type and anti-corrosion type. The cost of the ordinary type is relatively low, and the price of the anti-corrosion type is relatively expensive.

- The pressure levels are divided into 1.0MPA, 1.6MPA, 2.5MPA, 4.0MPA, 25MPA. The greater the pressure, the more expensive the price. So the pressure is directly proportional to the price.

- Every customer who has bought a radar level sensor knows that the installation method is different. Top-mounted and side-mounted. Because of the different structure, the top-mounted type is more expensive than the side-mounted type.

Sino-Inst provides customers with the most reasonable prices on the basis of ensuring product quality. Radar Level Sensor Price reference range: USD500-1500.00/pc

Extended reading: Solid flow meter | For bulk solids-powder-soybean-cement

Featured Radar Water Level Sensors

Frequently

Asked

Questions

Sino-Inst offers over 10 Microwave Radar Liquid Level Sensors for level measurement. About 50% of these are Radar level meters, 40% is the tank level sensor.

A wide variety of Microwave Radar Liquid Level Sensors options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of radar level measurement instrumentation, located in China.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.