As a clean energy, natural gas is widely used in many aspects such as industrial production, thermal power generation and residential gas heating.

Although natural gas pipeline transportation has many advantages, there are also risks such as leakage and failure. This can lead to interruptions or leaks in the delivery, causing significant financial losses and further safety risks. Therefore, sensors and data acquisition equipment are used for monitoring to achieve the purpose of leakage prevention and failure prevention. At the same time, risk issues such as distributed gas quality and consumption balance are monitored.

In the entire gas pipeline monitoring system, the detection of pressure-temperature-flow ensures operation, thereby preventing gas interruption.

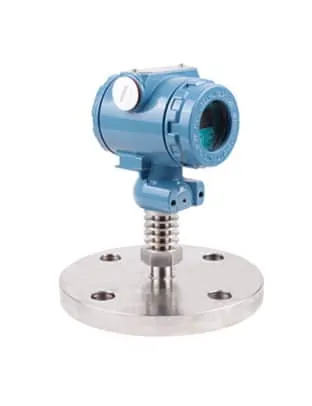

Natural Gas Pipeline Pressure Measurement

In the oil and gas sector, pressure sensors are fundamental components for a wide range of applications. The pressure sensor can be used to monitor the pipeline pressure in real time. Not only that, the pressure sensor is also used in the gas furnace to measure the pressure of the gas in the gas supply pipeline, so as to judge whether the gas is sufficient or whether it is leaking.

- Pressure transmitters play an important role in moving natural gas through thousands of natural gas pipelines. For monitoring natural gas pressure, measuring very low inlet and outlet pressures;

- Various pressure types are also involved in the measurement process. Such as gauge pressure, absolute pressure, differential pressure, high pressure and differential pressure, etc.;

- Special approval options such as ATEX Intrinsic Safety are available where natural gas may be present in the local atmosphere;

- Leaks and even explosions may occur if the gas pressure in gas and gas pipelines is too high;

- If the air pressure is too low, it will affect people’s daily use. Therefore, it is necessary to monitor the air pressure of each node through the pressure sensor, so that the air pressure is within a reasonable range;

- The gas pipeline pressure sensor generally adopts the threaded installation form, which is simple and convenient and easy to ensure the sealing of the product. The signal output of the gas pipeline pressure sensor has analog signal and digital signal, which belong to the remote transmission type signal.

Sino-Inst’s pressure transmitter can be matched with industrial control system PLC or configuration system to ensure the accuracy and reliability of the automation system. The most important thing to choose a gas pipeline pressure sensor is to consider the quality of the product. The Sino-Inst gas pipeline pressure sensor is made of a corrosion-resistant pressure core and a stainless steel outer protective shell thread to ensure the durability of the product. The signal expansion transmitter also uses imported electronic components to ensure the stability of the gas pipeline pressure sensor.

Regardless of oil drilling, extraction, or transportation, there are various challenges and difficulties in the application of pressure sensors in the oil and gas industry. For example, key issues such as cost control, safe construction and environmental protection. Our engineers have rich practical experience in this industry, can fully understand the problems and difficulties you actually encounter in the oil and gas industry, and provide you with pressure measurement solutions based on your needs, combined with our own technology.

Featured Natural Gas Pressure Transmitters

Monitoring of Natural Gas Pipeline Temperature

General-purpose temperature transmitter, suitable for temperature measurement of gas or liquid, such as air, natural gas, steam, water or engine oil and other non-corrosive media. At the same time, a variety of analog and digital signal outputs are available for selection. It is convenient for users to form a measurement and control system with other equipment.

The temperature transmitter is based on a standardized Pt100 or Pt1000 temperature sensing element, providing customers with accurate and stable temperature measurement. The product is cost-effective and can meet various application requirements. It is an ideal product for temperature measurement.

In addition to gas pressure detection, we also provide Industrial Gas Measurement with Digital Gas Mass Flow Meters.

Featured Temperature Transmitters

Natural Gas Pipeline Flow Monitoring

The flow measurement of natural gas is currently mainly used in trade settlement and is relatively common. my country’s natural gas trade measurement is based on the volume or energy method under the legally required quality indicators for transfer measurement. At this stage, volume measurement is basically the main method.

At present, the flowmeter products used for natural gas flow measurement generally include: gas waist wheel flowmeter, gas turbine flowmeter, precession vortex flowmeter, vortex flowmeter, ultrasonic flowmeter and orifice flowmeter.

Let’s make a simple comparison on the use of these flow meters.

Featured Natural Gas Flow Meters

More Gas Measurement Solution

In the entire gas pipeline monitoring system, the detection of pressure-temperature-flow is to ensure correct operation, thereby preventing gas interruption.

For the above characteristics, Sino-Inst provides high precision, good stability, low power consumption, easy to connect and supports customized pressure sensors, temperature sensors, flow meters, etc. Provide reliable pressure, temperature and flow monitoring support for gas pipeline monitoring.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.