Oil Level measurements are necessary to control the amount of oil in the tank and to prevent overflow. Oil Level measurements are very important in the process of oil and gas storage and transportation. We will analyze and introduce the automatic level measurement here. Hope to help you!

The Necessity of Oil tank level measurement

-In the process of oil and gas storage and transportation, accurately measure the height of the liquid level in the large oil storage tank. This is an important measure to correctly calculate oil storage, determine inventory, and calculate transportation.

-In oil and gas production, especially in oil and gas gathering, transportation, storage, and transportation systems, oil, natural gas, and associated sewage must be separated, stored, and processed in various production equipment and tanks. The measurement and control of the level are essential to ensure normal production and equipment safety. Otherwise, a major accident will occur.

-For example, if the oil tank level measurement is not well controlled, there will be evacuated or oil spill “roofing” accidents. If the liquid level of the oil-air separator is too high or too low, “oil running” and “gas blow-by” accidents will occur. Seriously affect the production and safety of subsequent equipment;

-The high oil-water interface in the electric dehydrator will destroy the electric field. If it is low, it will carry oil in the water and affect production.

The Basic Concept of Level

- Level—refers to the general term of the liquid level of the liquid medium, the level of solids or the level of particles in the container and the interface between two different liquid media.

- Liquid level-the height of the liquid medium in the container

- Material level-the accumulation height of solid or granular substances in the container

- Interface level – the level of the interface of two immiscible liquids medium

Extended Reading: How to Measure Volume of Liquid

Classification of Oil Level Measurement

According to the measurement method, it can be divided into continuous measurement and fixed-point measurement.

According to its working principle, it can be divided into the following types:

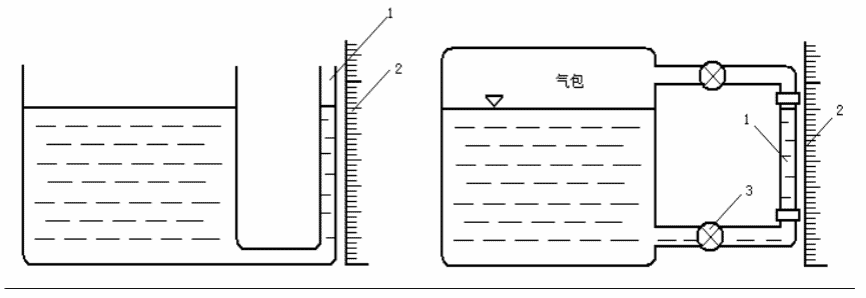

- Direct reading type It measures the liquid level based on the principle of fluid connectivity.

- Buoyancy type It measures the liquid level according to the principle that the height of the float changes with the height of the liquid or the buoyancy of the liquid to the float (or sinker) immersed in the liquid changes with the height of the liquid. The former is called constant buoyancy, and the latter is called variable buoyancy.

- Differential pressure type (static pressure type) It measures the level according to the principle of the change in the static (differential) pressure generated at a certain point by the change in the height of the liquid column or the material accumulation.

- Electrically, it measures the level based on the principle of converting level changes into various changes in electricity.

- Nuclear radiation type It measures the liquid level based on the principle that when the nuclear radiation of the isotope rays penetrates the material, its intensity changes with the thickness of the material layer.

- Acoustic It measures the level according to the changes in acoustic impedance and reflection distance caused by changes in the level

Read more about: 7 Level Senors for Tank Level Measurement

Still have questions?

If you cannot find an answer to your question in our FAQ, you can always contact us

and we will be with you shortly.

Performance characteristics and selection of common oil tank level gauges

The intermediate tank only monitors parameters such as liquid level, temperature, and pressure (pressure storage tank) to prevent accidents such as roof capping and vacuuming of the oil tank. There is no need for handover monitoring and measurement;

The liquid level, temperature, density, volume, and quality of the medium in the trade tank must be monitored and measured frequently, and the accuracy is very high.

Performance comparison of Oil level measurement

| Level gauge | Light oil | Crude oil | Heavy oil | Asphalt | Liquefied gas | Other liquids |

| Magnetic flap level gauge | ok | ok | ok | poor | No | very good |

| Float | ok | ok | ok | poor | No | very good |

| radar | Great | Great | Great | Great | Great | Great |

| Static pressure | Great | Great | ok | poor | ok | Great |

| Magnetically induced | Great | Great | Great | poor | Great | Great |

| Ultrasonic | Great | Great | Great | Great | Great | Great |

Extended reading: Radar Oil Tank Level Sensor

Oil Tank level measurement instruments for different media

| Level gauge | Level measurement | Temperature deletion | Density deletion | Boundary measurement | Volume measurement | Quality deletion | Installation situation | Cost |

| Magnetic flap | High precision | Can not be measured | Can not be measured | Small error | Depends on TD | Depends on Tρ | simple | low |

| Float | High precision | Can not be measured | Can not be measured | Mistaken sheep | Depends on TD | Depends on Tρ | simple | low |

| radar | High precision | important | Unable to delete | Unable to | Small error | Depends on Tρ | simple | high |

| Hydrostatic pressure | Big error | unimportant | Small error | Unable to | Big error | Depends on Tρ | complex | Relatively high |

| Magnetically induced | High precision | important | Unable to delete | High precision | Small error | Depends on Tρ | complex | high |

| Ultrasound | High precision | unimportant | Can not be measured | Unable to | Small error | Depends on Tρ | complex | high |

Explore Oil and Gas Flow Meters

Selecting Guide for Oil level measurement

- Oil tank volume

- ·For large tanks (10000~100000m3) and relatively large liquefied gas tanks, higher performance level gauges can be used, and general level gauges can be used for medium and small tanks;

- Read more about: Ultrasonic Tank Level Sensors for Tank Level Monitoring

- ·Oil tank use

- High-precision level gauges should be used for trade tanks, and general level gauges can be used for intermediate tanks;

- Medium characteristics

- When storing high-viscosity media (such as heavy oil), try to use a level gauge that does not or has little contact with the measured medium. Such as radar type, ultrasonic type and magneto-induced level gauge, light oil can use general level gauge;

- Actual needs of users

- ·If the user requires high measurement accuracy and low investment restrictions, a level gauge with good performance can be used. Under normal circumstances, the old tank area can be retrofitted or updated according to the use and maintenance of the original level gauge.

Extended reading: The Secret of Ultrasonic Level Measurement

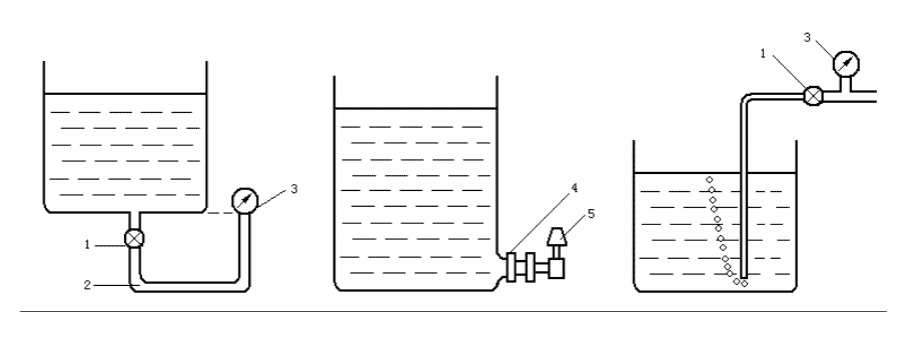

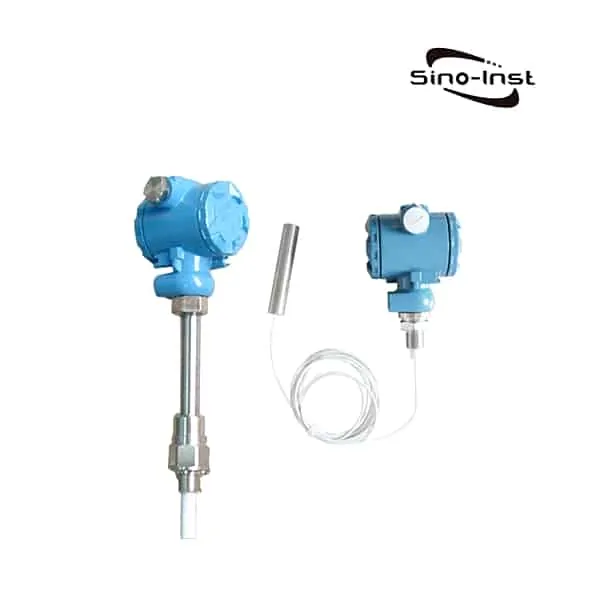

Featured Oil level measurement devices

Frequently

Asked

Questions

Read more about: Capacitive Level Measurement System

Sino-Inst offers over 50 Solutions for Tank Level Sensing. About 50% of these are float liquid level meters, 40% are the level switches.

A wide variety of Solutions for Tank Level Sensing options are available to you, such as free samples, paid samples.

Sino-Inst is a globally recognized supplier and manufacturer of Solutions for Liquid Level Measurement instrumentation, located in China.

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.