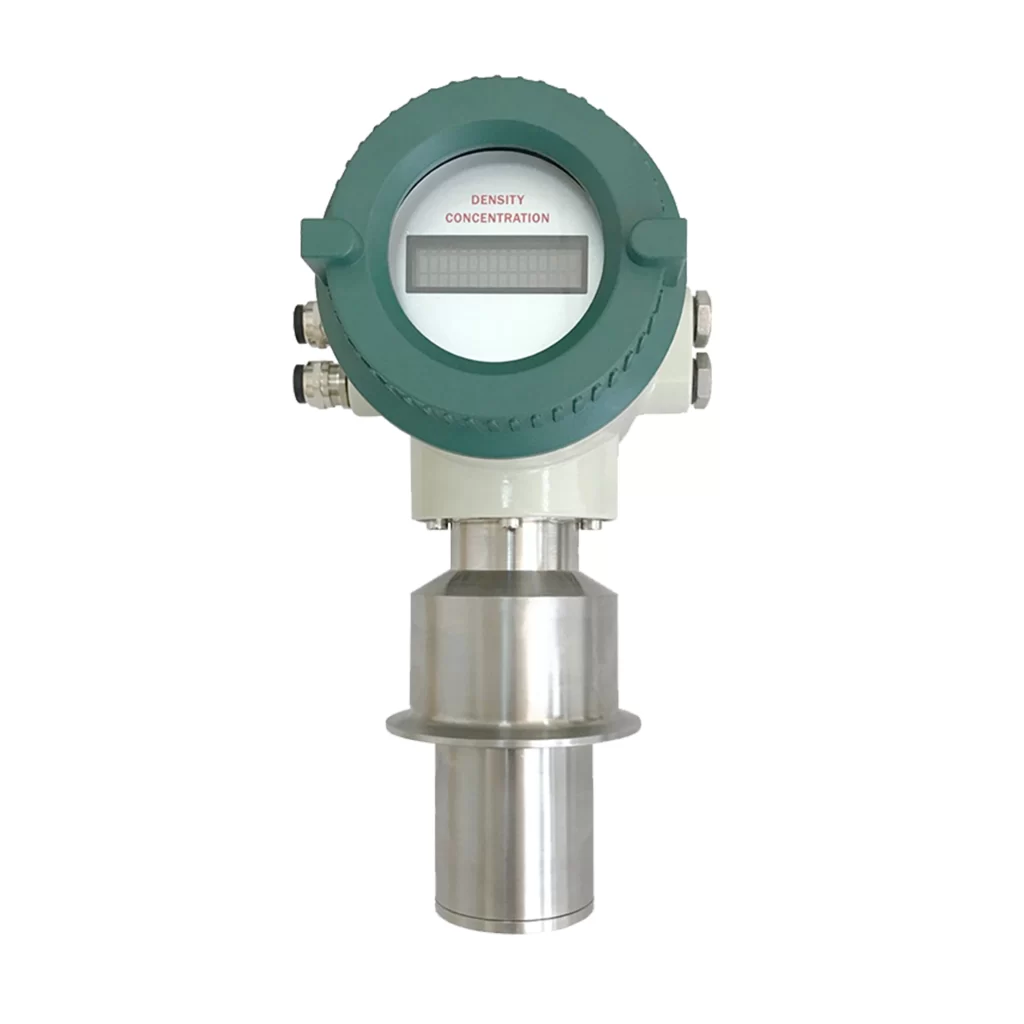

Alcohol Density Meter is also called Alcohol Concentration Meter. The Online Alcohol Density Meter uses an acoustic frequency signal source to excite the metal vibrator. And make the vibrator vibrate freely at the center frequency. This frequency correlates with the density of the contacting liquid. Therefore, the density of the liquid can be measured by analyzing the frequency. Further temperature compensation can eliminate the temperature drift of the system. As for the concentration, the standard wine concentration value at 20°C can be calculated according to the relational formula corresponding to liquid density and concentration.

Features of Online Alcohol Density Meter

- With analog signal 4 ~ 20mA and digital signal RS485 remote transmission;

- Real-time display of standard alcohol content at 20°C; real-time indication of alcohol concentration and temperature;

- You can directly enter the instrument menu to set parameters and debug on site, which is easy to operate;

- It has the functions of pure water calibration, fine-tuning of measured value and temperature compensation;

- Online real-time measurement, which can be directly used for production process control;

- The parts in contact with the liquid are made of 316 stainless steel, which is safe, hygienic and has good corrosion resistance.

Technical Parameters

| Signal mode: | Four-wire system |

| output signal: | 4~20 mA (active output) or RS 485 (Modbus RTU standard protocol, communication rate 9600) |

| power supply: | 24VDC (resistive elements cannot be loaded externally or connected in series with PLC) |

| Measuring range: | 0~100%, according to the usage, can be calibrated to measure in a certain range |

| Accuracy: | 1%, |

| Explosion-proof grade: | Ex dIIB T6 Gb |

| Work pressure: | < 1 MPa |

| Operating temperature: | – 10~ 85℃ |

| Electrical Interface: | M 20×1.5 |

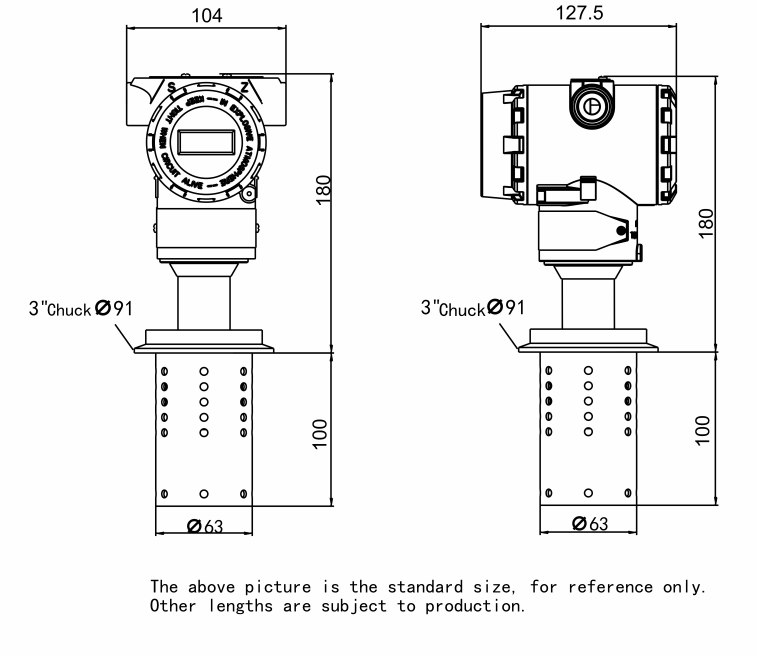

| Process interface: | 3〞Sanitary Quick Release Chuck Ø91 or 2〞Sanitary Quick Release Chuck Ø64 |

| Wetted parts: | 316 stainless steel |

| The accuracy | ±0.001g/cm3 | ±0.25% |

| The scope of work | 0~2g/cm3 | 0~100% |

| repeatability | ±0.0001g/cm3 | ±0.1% |

| Process temperature effect (corrected) | ±0.0001g/cm3 | ±0.1% (per ℃) |

| Process pressure effect (corrected) | can be ignored | can be ignored |

(1) The above accuracy applies to the calibration range of 0.8–1.5g/cm3 (800–1500 kg/m3).

(2) The maximum viscosity of the liquid can reach 2000cP.

(3) Temperature effect refers to the maximum measurement deviation caused by the process fluid temperature deviating from the factory calibration temperature.

(4) Pressure effect is defined as the change in sensor flow and density sensitivity due to process pressure deviation from calibration pressure.

| Process temperature | Standard: –25℃~+120℃ |

| Customized: –25℃~+150℃ | |

| Ambient temperature | –25℃~+85℃ |

| Temperature Coefficient | 20ppm/℃ (after calibration) |

| Built-in temperature sensor | temperature chip |

| Working pressure | Standard | Within 2.5MPa |

| Special custom | Within 6.3MPa | |

| Test pressure | Tested at 1.5 times the maximum working pressure | |

| Actual maximum working pressure is limited by process connection rating | ||

Online Alcohol Density Meter applications

The online alcohol density meter uses a sound wave frequency signal source to excite the metal vibrator. And make the vibrator vibrate freely at the center frequency. This frequency correlates with the density of the contacting liquid. Therefore, the density of the liquid can be measured by analyzing the frequency. Further temperature compensation can eliminate the temperature drift of the system. As for the concentration, the concentration value at a temperature of 20°C can be calculated according to the relationship between the corresponding liquid density and concentration.

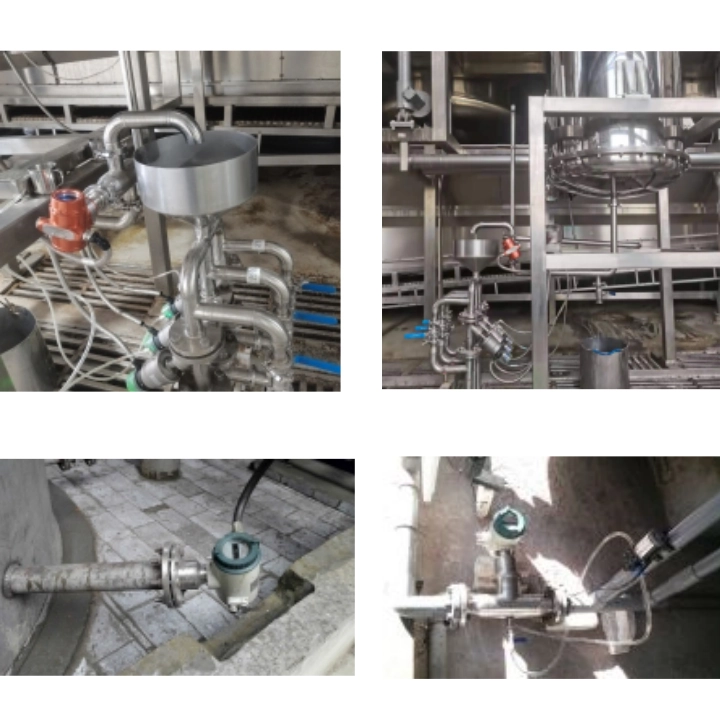

Liquor concentration, density and temperature measurement in liquor production process section:

- Alcohol degree measurement in the wine picking process during the brewing stage;

- Monitoring of alcohol content in wine storage tanks;

- Measurement of the concentration of blended craft wine;

- Measurement of alcohol concentration in filling;

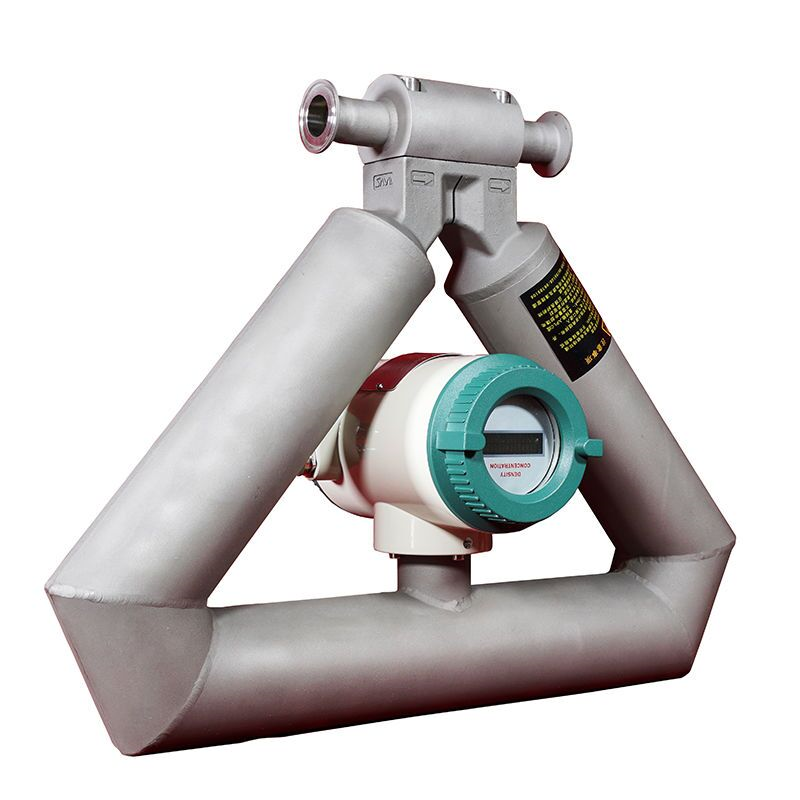

Online Alcohol Density Meter is suitable for various ways such as pipeline installation or container wall insertion installation. Both dynamic and static measurements can be made. Installation method Sanitary quick-loading chuck type.

Alcohol Density – Concentration Measurement Solution

Online Alcohol Density Meter for Comprehensive wine extraction

The production line of the distillation workshop needs to carry out comprehensive collection of alcohol concentration and implement intelligent and digital production first. The grains in the tower are distilled and the wine flows into the tank through the condenser.

The system will distinguish the main effective wines of the head and tail wines according to the concentration of the wines. Equipped with a main fully closed sanitary automatic control valve. Guarantee the qualified delivery conditions for comprehensive and effective liquor. This process section is mostly used for Maotai-flavored wine picking.

The first stage: As the distillation time progresses, what follows is a head with impurities. The system sets the collection and control of wine head by time. About 5kg, at this time the valve opens. The wine head flows into the tank until the set time is reached, and the valve is closed. It can be adjusted according to different liquor brewing processes.

The second stage: the main wine is collected comprehensively through wine tanks. Measure the alcohol concentration in real time with an alcohol density meter to ensure that the comprehensive alcohol content reaches the qualified alcohol content and make effective adjustments.

The third stage: tail wine collection. When the alcohol content is less than the minimum setting, close all valves. Open the tail valve for effective collection.

Online Alcohol Density Meter for Segmented wine extraction

The production line of the distillation workshop needs to collect the alcohol concentration in sections and take the lead in implementing intelligent and digital production. The grains in the tower are distilled and the wine flows into the tank through the condenser. The system will be divided into the following three stages of control according to the different alcohol concentrations, with a fully closed sanitary automatic control valve.

The first stage: With the passage of distillation time, the wine head with impurities comes out. The system sets the collection and control of the wine head through time. It is about 5kg. At this time, the valve opens. The wine head flows into the tank. Until When the set time is reached, the valve closes. It can be adjusted according to different liquor brewing processes.

The second stage: After the separation of the beer head is the focus of the process. At this time, the valve is opened, and the system needs to collect and store the puree with alcohol concentration of Luzhou-flavored (75%~55%)/sesame-flavored (≥20%) in the tank. Carry out grading, and when the corresponding alcohol content range is reached, the corresponding valve is opened for grading collection. When the concentration meter detects that the alcohol content is lower than the minimum range value, the valve is closed. Remarks: Because different brewing processes require different degrees of alcohol extraction, the system can directly set and extract alcohol degrees according to the actual needs of the winery.

The third section: Tail wine collection, when the alcohol content is less than the minimum setting, close all valves. Open the tail valve for effective collection.

FAQ

More Density meter and measurement analysis solution

What Is Density Meter? and Types

Liquid Level Sensor Probes Types and How to Select

Ultrasonic Level Transmitter Installation Guide

What Is the Ultrasonic CO2 Level Indicator? CO2 Bottle Level Measuring Device

Dew Point Monitor for the Fruit and Vegetable Industry

Radar Level Gauge – Everything You Should Know and Selection List

Alcohol production in alcohol factories is completed by multiple processes, mainly controlled by humans. In the process of distilling and extracting alcohol, operators have been operating with experience. Inevitably there are errors affecting the alcohol concentration, which can lead to production defects. The incoherence of the distillation process has largely led to the instability of alcohol, which has become a persistent disease that has plagued the alcohol industry for many years. For a long time, the wine industry has spared no effort to break through the traditional production process and realize production automation.

Our company Sino-Inst has been committed to the development and manufacture of density and concentration measuring instruments. After years of painstaking research and experimentation, it has finally successfully developed an environment that can adapt to the high temperature and humidity in the distillation and extraction process. Online Alcohol Density Meter-Alcohol Concentration Meter can promote the automation of distillation and extraction process in alcohol industry.

If you need Online Alcohol Density Meter-Alcohol Concentration Meter, please feel free to contact our sales engineers!

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.

Online Alcohol Density Meter-Alcohol Concentration Meter

Alcohol Density Meter is also called Alcohol Concentration Meter. The Online Alcohol Density Meter uses an acoustic frequency signal source to excite the metal vibrator. And make the vibrator vibrate freely at the center frequency. This frequency correlates with the density of the contacting liquid. Therefore, the density of the liquid can be measured by analyzing the frequency. Further temperature compensation can eliminate the temperature drift of the system. As for the concentration, the standard wine concentration value at 20°C can be calculated according to the relational formula corresponding to liquid density and concentration.

Product SKU: Online Alcohol Density Meter-Alcohol Concentration Meter

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 3999

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5