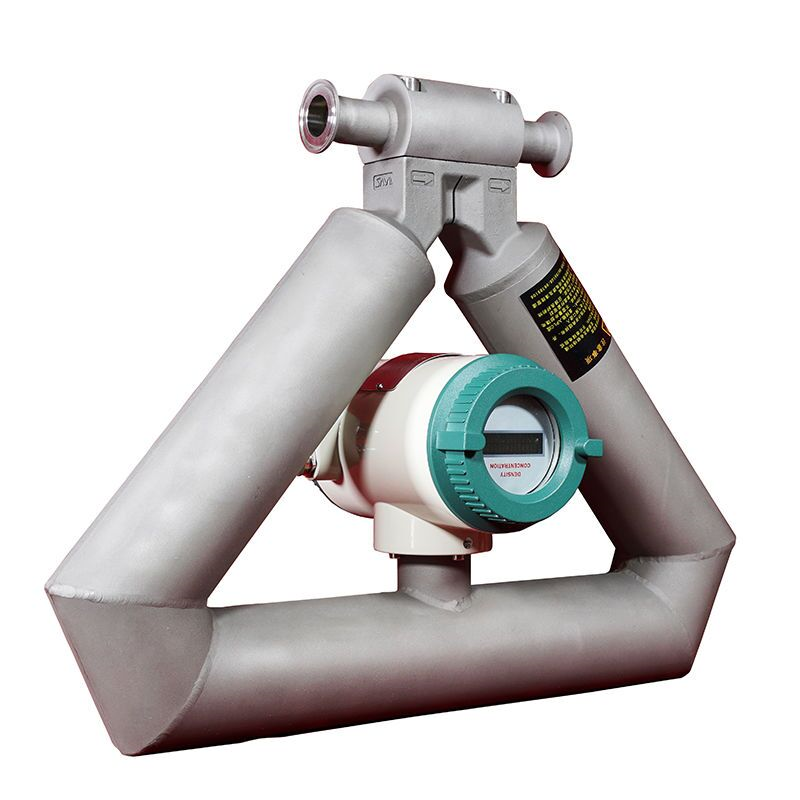

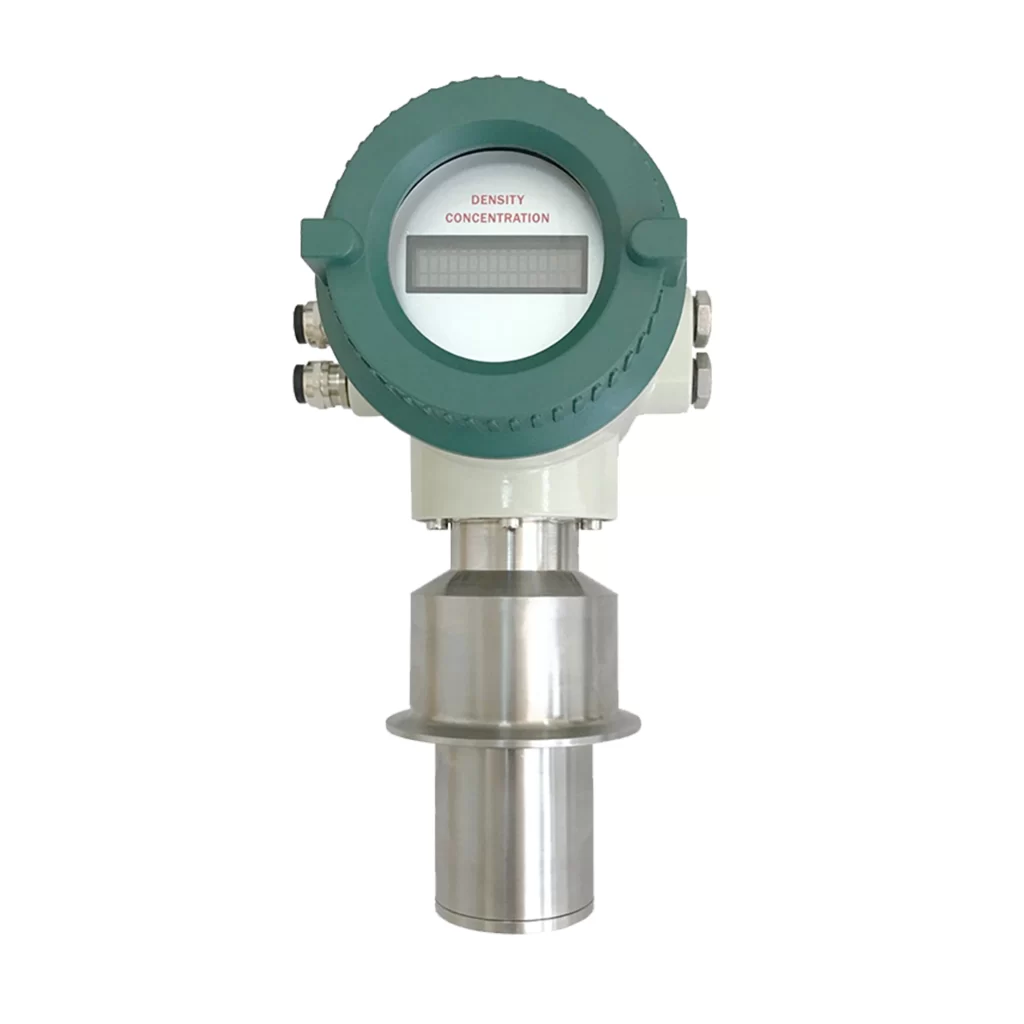

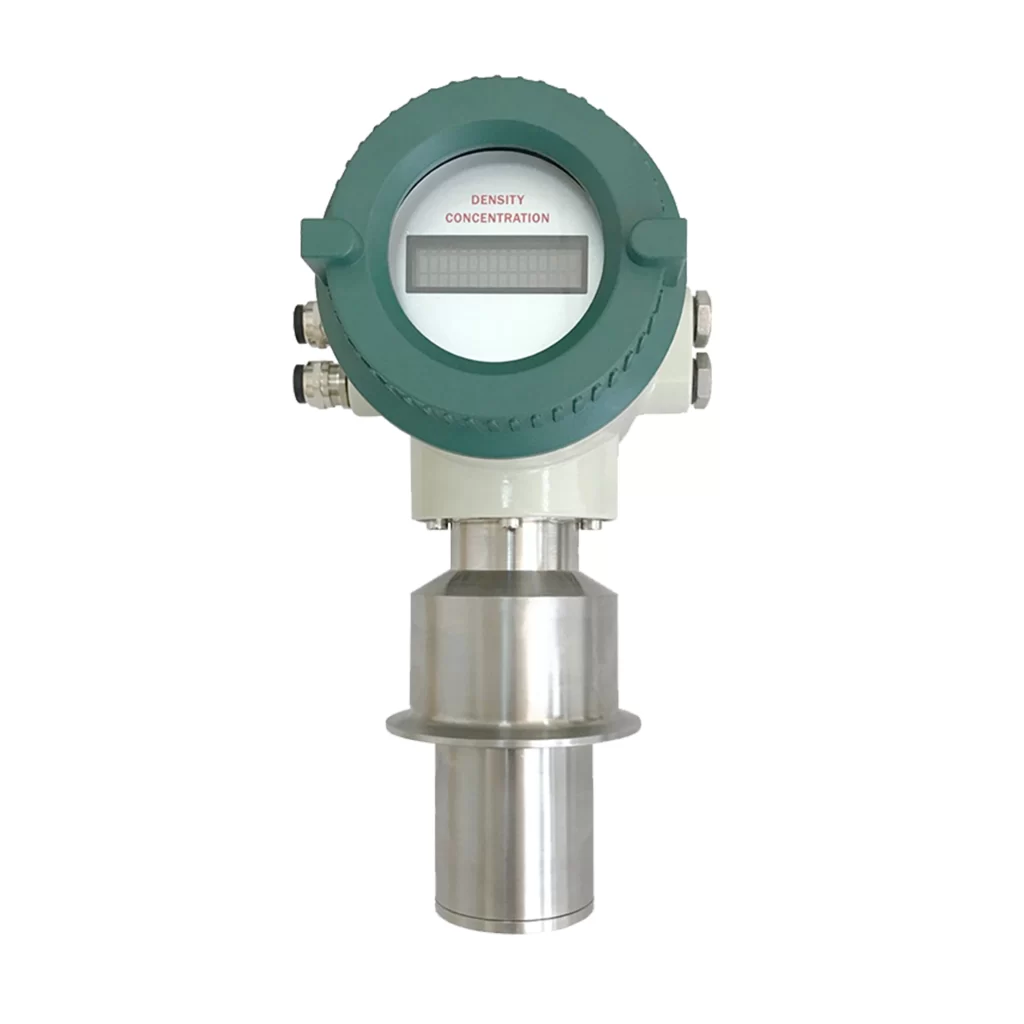

Optical Density Meter is a Liquid Densitometer. Using the propagation law of the spectrum in the liquid, sampling is carried out through a high-resolution spectral sensor. The analysis and calculation process is carried out by the software to obtain the regularity of the concentration. Then through temperature compensation, the concentration of various liquids or liquid mixtures can be measured. The Optical Density Meter is suitable for installation in pipes or on vessel walls. It is widely used to measure the density of liquids with certain transparency. Some examples are ammonia water concentration, Brix sugar refining (sugar concentration). Other examples include sodium hydroxide, potassium hydroxide, sodium carbonate, carbamide, ammonia water, and hydrogen peroxide.

Features of Optical Density Meter

- Fully integrated “plug and play, maintenance-free” digital measurement for monitoring and control;

- Provide materials including 316L, PTFE, etc.;

- continuous measurement;

- No moving parts, less maintenance;

- Concentration 4-20mA output;

- Provide temperature sensor;

- Suitable for a variety of acids, alkalis, organic solutions;

- Not easily affected by temperature and flow rate;

- Suitable for installation in tanks and pipelines;

- A small amount of solids and air bubbles are allowed;

- Passed explosion-proof certification;

Technical Parameters

| Accuracy | ±0.5% |

| The scope of work | 0~100% (20°C), according to the usage, it can be calibrated to a certain range |

| repeatability | ±0.2% |

| Process temperature effect (corrected) | ±0.001% (per ℃) |

| Process pressure effect (corrected) | can be ignored |

| Process temperature | –10℃~+60℃ |

| Ambient temperature | –10℃~+45℃ |

| Temperature Coefficient | O.1%/m3/℃ (after correction) |

| Built-in temperature sensor | temperature chip |

| Wetted parts | 316L, polytetrafluoroethylene |

| Glass | Acid and alkali resistance |

| Shell | IP65, aluminum alloy |

| Working pressure | 0.8MPa |

| Test pressure | Tested at 1.5 times the maximum working pressure |

| Actual maximum working pressure is limited by process connection rating | |

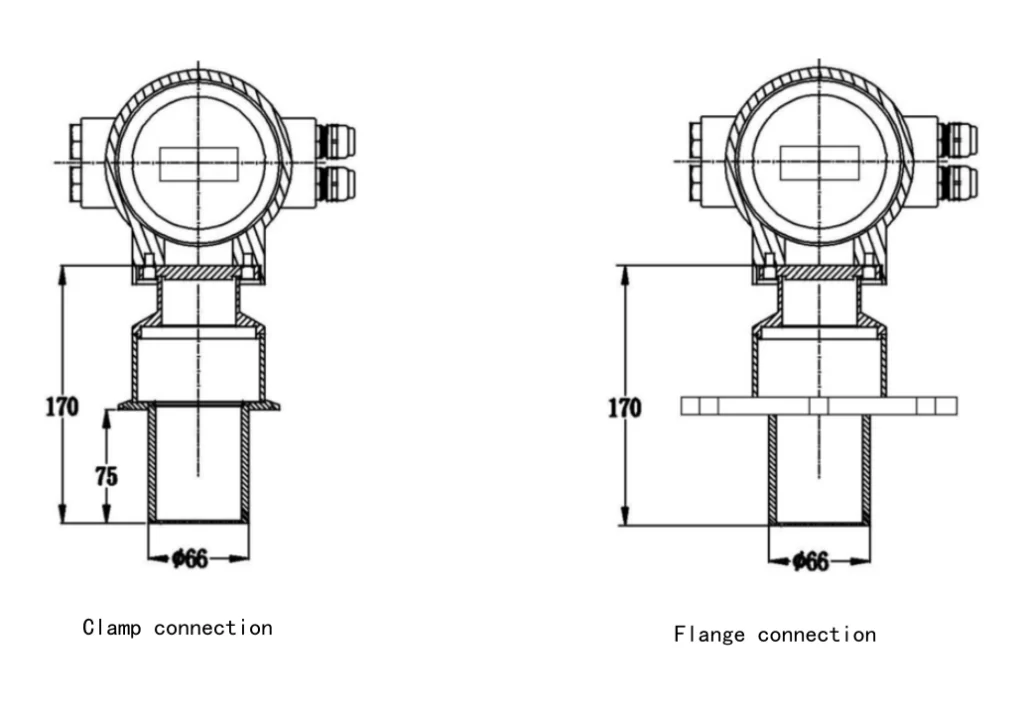

| Process connection type | flange |

| Clamp | |

| Explosion-proof certification | Ex d ⅡC T6 Gb |

| Power requirements | 24VDC,50mA |

| Output | Four-wire system, 4-20mA |

| Viscosity range | <5000MPa.s |

Fluid and Material Compatibility

| Type | Name | Molecular formula | Concentration (%) | 316L | Hastelloy | Titanium alloy | zirconium | PTFE |

| Acid | Hydrochloric acid (without hydrofluoric acid) | HCI | 0-40 | × | ○ | × | ☆ | ☆ |

| sulfuric acid | H2SO4 | 0-50 | ○ | ☆ | ○ | ☆ | ☆ | |

| H2SO4 | 50-75 | × | ○ | × | ○ | ☆ | ||

| H2SO4 | 75-98 | ○ | ☆ | ○ | ○ | ☆ | ||

| nitric acid | HNO3 | 0-100 | ○ | ○ | ○ | ○ | ☆ | |

| phosphoric acid | H3PO4 | 0-98 | × | × | × | × | ☆ | |

| Alkali | sodium hydroxide | NaOH | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ |

| Potassium hydroxide | KOH | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ | |

| Calcium hydroxide | Ca(OH)2 | 0-50 | ☆ | ☆ | ☆ | ○ | ☆ | |

| Salt | Sodium chloride | NaCl | 0-50 | × | ☆ | ☆ | ☆ | ☆ |

| ammonium chloride | NH4Cl | 0-50 | × | ☆ | ☆ | ☆ | ☆ | |

| ammonium sulfate | (NH4)2SO4 | 0-50 | × | ☆ | ☆ | ☆ | ☆ | |

| Others | carbamide | (NH2)2CO | 0-100 | ☆ | ☆ | ○ | ☆ | ☆ |

| sodium hypochlorite | NaOCI | 0-16 | × | ○ | × | ☆ | ☆ | |

| hydrogen peroxide | H2O2 | 0-90 | ☆ | ☆ | ○ | ☆ | ☆ | |

| ☆Recommended ○ Use under specific concentration and temperature limits × Do not use | ||||||||

Working principle of Optical Density Meter

Imagine you have a flashlight. When you shine it through a clear glass of water, almost all the light passes through. But if you shine it through a dark-colored drink, less light will pass through because the drink is denser.

An Optical Density Meter works a bit like that flashlight. It uses light to see how “thick” or “dense” a sample is. Here’s how:

Light Source: The meter has a light that shines through the sample.

Sample: This is what you want to test, like a liquid.

Detector: On the other side of the sample, there’s a part that catches and measures the light that comes through.

If a lot of light passes through, the sample is less dense. If only a little light passes through, the sample is more dense.

The Optical Densitometer is Based on the Propagation Law of the Spectrum in the Liquid. Sampling is Performed by High-Resolution Sensor. Analyzed AN d processed by software. Obtain the Regularity of the Concentration. The then Through Temperature Compensation. various liquids or liquid mixtures.

| Medium limit | bubbles, flow rate | Maximum Liquid Viscosity | |

| Particles | transparent | ||

| Trace particles | clear, pure liquid | a small amount of bubbles | 5000MPa.s |

| Velocity > 1.5m/s | |||

Video: https://www.youtube.com/embed/N8DOxmFBrhE

Optical Density Meter Industrial Applications

Imagine factories where they mix and create things like paint, drinks, or even medicine. They need to make sure everything is just right – not too thick, not too thin, and with the right amount of ingredients. That’s where the Optical Density Meter comes in handy.

- In the petrochemical industry, it can be widely used in the detection of petroleum, oil refining and oil blending;

- In the food industry, it is used in the production sites of grape juice, tomato juice, fructose syrup, vegetable oil and soft drink processing;

- dairy industry;

- paper industry;

- Measurement of alkaline solution;

- brewing alcohol;

- Printing and dyeing industry: measure ammonia concentration.

- Organic and Inorganic Chemical Materials: Sodium Hydroxide.

- Measurement of chemical carbamide, detergent, ethylene glycol, acid-base and polymer density.

- It can also be used in mining brine, potash, biopharmaceutical and other industries.

- Brewing and Beverages: Companies that produce beverages such as fruit juice or beer use this tool to check sugar content. More sugar means the drink may be sweeter and thicker.

- Pharmaceutical Manufacturing: When companies manufacture pharmaceuticals, they need to ensure that the mixture is perfect. A gauge can help check this.

- Paint making: Have you ever noticed that some paints are thick and some are thin? The factory uses a densitometer to get just the right consistency.

- Water Treatment: This meter can help check how clean the water is. If the water is too “thick” and contains unwanted material, more cleaning may be required.

- Agriculture: Farmers use it to check the health of plants. If plants are not healthy, they may not be able to absorb enough light. Meters can provide relevant clues.

These are just a few examples. There are many places where knowing how “thick” or “dense” something is can be very useful, and that’s why the Optical Density Meter is an important tool in industries.

Typical applications:

| Denitrification industry | — Measure ammonia concentration (0~30%) |

| Wine industry | — Quality control — Continuous online inspection |

| Organic and Inorganic Chemical Materials | — Acid/base concentration control |

| Pharmaceutical Industry | — Traditional Chinese medicine concentration, alcohol recovery |

| Battery industry | — concentration of lithium hydroxide, electrolyte, sulfuric acid solution |

| Mineral processing | Clay, carbonate, silicate |

FAQ

More Density meter and measurement analysis solution

Top Liquid Flow Meters in Industry

Liquid Level Sensor Probes Types and How to Select

Dew Point Monitor for the Fruit and Vegetable Industry

What Is a Dew Point Monitor and How to Choose One?

What Are Flow elements? Guide for Different Types of Flow Elements

Optimize Filtration Monitoring with Differential Pressure Sensors

When it comes to measuring the “thickness” or “Density” of liquids, the Optical Density Meter-Liquid Densitometer is a top choice.

Optical Density Meter-Liquid Densitometer uses the law of spectrum propagation in liquid to measure the density of transparent liquid. The liquid must have a certain degree of transparency, which is suitable for pipeline installation or installation on the wall of the container.

Our Sino-Inst Optical Density Meter is widely applicable to the concentration of various liquids or liquid mixtures.

At Sino-Inst, we aren’t just Optical Density Meter supplier – we’re experienced manufacturer. We understand the ins and outs of Optical Density Meter because we’ve crafted it with care. Need something special? We support customizations to meet your specific needs. Trust in our experience and expertise. Ready to elevate your measurements? Choose Sino-Inst today!

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.

Optical Density Meter-Liquid Densitometer | Sino-Inst

Optical Density Meter is a Liquid Densitometer. Using the propagation law of the spectrum in the liquid, sampling is carried out through a high-resolution spectral sensor. The analysis and calculation process is carried out by the software to obtain the regularity of the concentration. Then through temperature compensation, the concentration of various liquids or liquid mixtures can be measured. The Optical Density Meter is suitable for installation in pipes or on vessel walls. It is widely used to measure the density of liquids with certain transparency. Some examples are ammonia water concentration, Brix sugar refining (sugar concentration). Other examples include sodium hydroxide, potassium hydroxide, sodium carbonate, carbamide, ammonia water, and hydrogen peroxide.

Product SKU: Optical Density Meter-Liquid Densitometer

Product Brand: Sino-Inst

Product Currency: USD

Product Price: 6800

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5