Pressure transmitters are electronic type pressure transducers, with Capacitive or diffused silicon sensors. Pressure transmitters, or called pressure transducers, convert pressure into an analog electrical signal. By connection, there are flush mount, tri clamp, and more. By output, there are analog, 4-20mA, 0-5V, and more. All pressure transmitters, with maniflod installation, can work for industrial tank. And, there more types pressure transmitters, like: differential pressure transmitter, submersible pressure sensor. And high temperature type pressure transmitter, or wireless pressure transmitters, can be customized. Although there are various types of pressure transducers, one of the most common is DP type.

Industrial Pressure Transmitters

Pressure transmitters, with industry-leading performance, improve operations in a wide range of industries .Ideal for OEMs, process applications, water processing, and industrial pressure applications. Sino-Instrument provides advanced design and manufacturing of pressure transducers and transmitters. For applications across Test and Measurement, Automotive, Medical, and more. Sino-Inst offer various materials, outputs, sensor technologies, and third-party approvals to meet various customer needs for measuring liquid or gas pressure.

Choose the right pressure transducer for your application:

Silicon Pressure Sensors

Low pressure tra nsducer, also called low pressure transmitter.

With the flush diaphragm, can be used in the HVAC system.

Sanitary Pressure Transmitter, also called tri clamp pressure transmitter,

is the pressure transducer with the flush diaphragm (flat membrane) as the pressure sensor.

The SI-300 4-20mA/ Voltage Pressure Transducer,

also called pressure transmitter 4-20mA,

is a pressure sensor with 20ma/Voltage output.

Industrial Pressure Transmitter, are precision engineered to fit most industrial pressure measurement applications.

The SI200 pressure transducer is designed to meet the operational requirements,of demanding pressure measurement applications,where good quality, fast delivery and low cost are of the highest priority..

Explosion-proof Pressure transmitter, or explosion-proof pressure transducer, with the explosion-proof enclosure.

The SI200 series of OEM general-purpose pressure transducers are designed for applications,

where economical price and reliable pressure measurement is required.

Silicon pressure sensor, also known as Diffused silicon pressure sensor. Piezoresistive diffusion silicon pressure transmitter, Silicon pressure transducer, also are this pressure sensors.

Sino-Instrument supplies High-temperature pressure transmitters with a 4-20mA output.which has a temperature capability of over 700 °C and is not pyroelectric.

The Gauge Pressure Transmitter SMT3151 TGP,

has been specially designed for the process industry,

and measures vacuum, gauge and absolute pressure ranges of gases, steam, fluids, and dust up to 600 bar.

Hydrostatic Level Sensors

Hydrostatic Level Sensor (Best Price), also called Hydrostatic level transmitter. Continuous level measurement in liquid applications with pressure sensors.

Liquid pressure sensor is widely used for pressure measurement of various liquids. Like water or oils. IP68 waterproof.

Submersible pressure transducer with 4-20mA output,

is normal submersible pressure transmitter for level measurement.

Hydrostatic level transmitter is also called hydrostatic level gauge. The rod-type Hydrostatic level transmitter 4-20mADC standard signal output. Flange or threaded installation. Can withstand high temperatures up to 450 ℃.

Well water level sensor is to apply Hydrostatic Level Sensor to deep well. Well water level sensor submerged in deep well work together with submersible water pump. Range 300m ~ 1000m.

Submersible Level Transmitter is made of Anti-corrosive all-tetrafluoroethylene(PTFE) material. It has high temperature resistance, corrosion resistance and anti-clogging.

Capacitive Pressure Sensors

A gauge pressure (GP) transmitter,gauge pressure transducer,also called gage pressure transmitter,compares a process pressure against local ambient air pressure.

Static pressure transducer, also called static pressure transmitter, is the pressure transducer with the current output pressure,which can be the digital pressure trasmitter, or the piezoelectric pressure transmitter.

Absolute pressure transmitters, also known as absolute pressure transducer,and absolute pressure sensor.Absolute pressure sensors and gauges produce readings, that are not influenced by atmospheric pressure.

HH3151 HART Pressure Transmitter,

4-20mA, Explosion-proof, HART (work with hart communicators),so, you can calibration your pressure transmitters by hart communicators,like: AMS TREX Device Communicator.

Wireless Pressure Transmitters

Battery-Powered Self-Contained Pressure Monitoring Solution.Sino-Instrument’s wireless pressure transmitters are extremely efficient,due to their unique energy management based on an ultra-low-power design.

Wireless pressure transducer, is the pressure transmitter that can send remote singal, RS485, RS232. Transmission distance is 1000m.Wireless pressure transducer can be pressure sensor, and diffferential pressure transmitter.

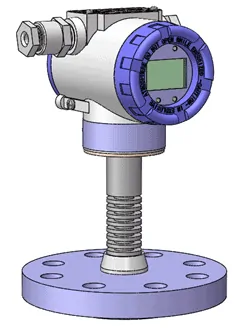

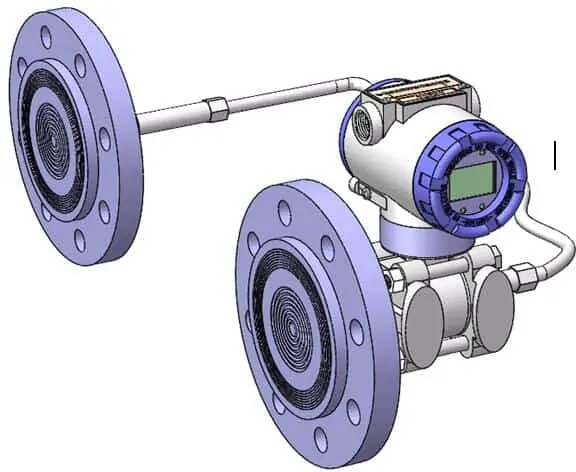

Diaphragm Seal Pressure Transmitters

Diaphragm Seals also referred to as chemical seals,

are used in applications,where the pressure sensor requires isolation from the process media.

These applications may be corrosive, high temp, clogging,or need a sanitary fluid to remain captured in the piping or vessel.

Diaphragm seal pressure transmitter, diaphragm seal DP transmtter, also called remote pressure transmitters. Diaphragm seal pressure transmitter is the direct mount type pressure transducer. Diaphragm seal differential pressure transmitter is the Remote type. This Diaphragm seal connection can work with the capillary, flange and manufold.

The Diaphragm pressure gauge type MPE is used to measure gases and liquids.The MPE diaphragm pressure gauge application spans from 10 mbar to 60 bar.The measuring element consists of one circular diaphragm,clamped between a pair of flanges.

Differential Pressure Transmitters

The Smart Differential Pressure transmitter is upgraded differential pressure transmitter, which can work with display, HART communicators, and 4-20mA output.

SMT3151LT Differential pressure (DP) level transmitter

a new type of differential pressure (DP) transmitter produced by advanced technology and equipment.

High-performance level measurement using a differential pressure transmitter.High-reliability micro-capacitance silicon cell.All welded construction with no flange ‘O’ rings.Exceptional resistance to harsh environments

The SI-D2000 Differential Pressure Gauge (Digital differential pressure gauge)

is an economical means for measuring pressure between two independent pressure sources.

Differential Pressure Transmitter Technology

4-20 mA Output Pressure Transducers

These types of transducers are also known as pressure transmitters,work with HART communicators.Since a 4-20mA signal is least affected by electrical noise,and resistance in the signal wires, these transducers are best used when the signal must be transmitted long distances. It is not uncommon to use these transducers in applications where the lead wire must be 1000 feet or more.

People also ask

How does a pressure transmitter work?

The functional principle of a resistive pressure transmitter is very simple. The pressure sensor converts the mechanical pressure value into a proportional electrical signal. The pressure sensor typically consists of a stable main body and a (thin) diaphragm. The diaphragm is the most important element for the measurement of the pressure,and is equipped with strain-sensitive and compression-sensitive resistance structures, so-called strain gauges (DMS). The diaphragm is deflected under the influence of pressure. Thus, the strain gauges attached to it are elongated or compressed and its electrical resistance changes. This change in resistance is directly proportional to the pressure. For example, if the resistors are wired to a Wheatstone measuring bridge, the resulting electrical signal can be measured and transferred to an indicator.

What is the difference between pressure gauge and pressure transmitter?

Gauge Pressure Transmitters: Gauge pressure transmitters, which sense gauge pressure, are referenced to atmospheric conditions. Gauge transmitters are vented to atmospheric pressure rather than to an absolute vacuum. Gauge pressure transmitters are widely used in the process industries to measure the pressures of liquid, gas and steam. Both absolute and gauge pressure transmitters are growing in part by replacing pressure gauges, switches, and transducers. Pressure transmitters are more stable and reliable than pressure transducers. As end-users increasingly automate their operations and also build new plants, they are more likely to choose pressure transmitters over pressure transducers. Absolute and gauge pressure transmitters also have the advantage that, unlike differential pressure transmitters used for flow, they do not have another technology that is replacing them.

Pressure Transmitters While pressure sensors can detect variations in pressure by converting changes in resistance or capacitance to electrical values, these electrical signals are relatively weak. These signals are not strong enough to be transmitted over distances, or sent to a controller that may be located at a long distance from the pressure sensor. To accomplish this, a pressure transmitter is required. A pressure transmitter contains a pressure sensor plus a signal conditioner to amplify the output from the pressure sensor. Pressure transmitters also typically contain a display that shows the pressure value that is conveyed by the pressure sensor and converted into a standardized output. This output is typically either 4-20mA or a digital signal. There are four main types of pressure transmitters: absolute, gauge, differential pressure, and multivariable.

How do differential pressure transmitters work?

The most common and useful industrial pressure measuring instrument is the differential pressure transmitter. This equipment will sense the difference in pressure between two ports and produce an output signal with reference to a calibrated pressure range.

DPT series pressure transmitters represent the latest development in their class.

The digital sensor makes measuring pressure even more accurate than before.

Fully automated zero point calibration, AZ-calibration,

offers reliability in the most sensitive of applications.

Besides, it provides cost savings over the lifetime of a building,

as it makes the device completely maintenance free.

Applied pressure readings are acquired by the diaphragms, which register pressure as surface deformation, and translate that value into an electronic signal.This signal is transferred to the differential pressure module, which compares the two values and expresses the pressure difference, as a value of pounds per square inch (psi), bar, or kilopascals (kPa).These diaphragms are all-welded to maintain container integrity, in vacuum conditions and for wet leg applications, such as level measurement in crude oil distilleries.

More:

What is pressure indicator transmitter?

Pressure indicator transmitters have a digital indicator for providing a local indication of pressure reading, and a 4-20 milliamp output pressure transmitter for sending an analogue signal to control & monitoring instrumentation. The built-in digital indicators can be scaled via push buttons or adjustment pots to any pressure unit or a 0-100% full scaling. No additional external supply is required, since the digital indicator is powered by the 4-20mA current loop from the pressure transmitter.

Further reading: How Often Should You Calibrate A Pressure Transmitter?

Sino-Instrument offers over 20 Pressure Transducers.

About 50% of these are 4-20ma Low-Pressure Transducers, 40% are Differential Pressure Gauge, and 20% are Diaphragm Seal Pressure transmitters, 20% are 4-20ma differential pressure transmitters.

A wide variety of Pressure Transducers options are available to you, such as free samples, paid samples.

Sino-Instrument is a globally recognized supplier and manufacturer of

Pressure Transducers, located in China.

The top supplying country is China (Mainland), which supply 100% of

Pressure Transducers respectively.

Sino-Instrument sells through a mature distribution network that reaches all 50 states and 30 countries worldwide.

Low-Pressure Transducers products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.