What is radar level meter?

A radar level meter is an ingenious device that uses radio signals to measure the level of materials in a container. They are user-friendly and safe, making them suitable for use in a variety of containers, be it metal or non-metal.

When it comes to measuring the level of liquids or grains in a tank or pipe, radar level meters are the go-to devices. They work efficiently under various conditions – whether it’s hot, cold, or even in the presence of gases.

Featured Radar Level Meters

80 GHz radar sensor for continuous level measurement of liquids.

Sino-Inst also launched radar level sensor operating at 76-81 GHz.

Measuring range: 0.3~120 meters;

Accuracy: ±1mm

Application: various corrosive liquids

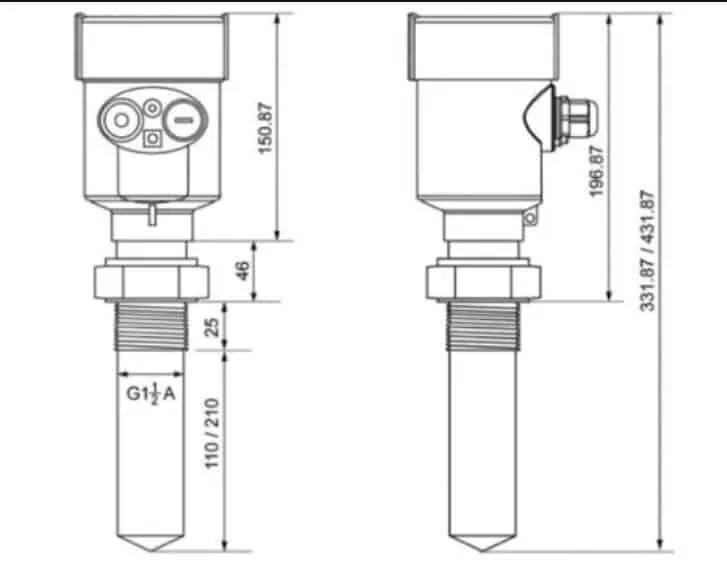

Measuring range: 10 meters

Process connection: thread, flange

Process temperature: -40~130℃

Process pressure: -0.1~0.3 MPa

Accuracy: ±5mm

Protection level: IP67

Application: solid mat

Application: temperature-resistant, pressure-resistant, slightly corrosive liquid

Measuring range: 30 meters

Process connection: thread, flange

Process temperature: -40~130℃ (standard type) / -40~250℃ (high temperature type)

Process pressure: -0.1~4.0MPa

Accuracy: ±3mm

Protection level: IP67

Application: corrosive liquid, steam, volatile liquid

Measuring range: 20 meters

Process connection: flange

Process temperature: -40~130℃ (standard type) / -40~250℃ (high temperature type)

Process pressure: -0.1~2.0MPa

Accuracy: ±3mm

Protection level: IP67

Frequency range: 26GHz

Application: rivers, lakes, shallows

Measuring range: 30 meters

Process connection: thread G1½ʺ A / bracket / flange

Process temperature: -40~100℃

Process pressure: normal pressure

Accuracy: ±3mm

Frequency range: 26GHz

Application: solid materials, strong dust, easy to crystallize, condensation occasions

Measuring range: 70 meters

Process connection: universal flange

Process temperature: -40~130℃ (standard type) / -40~250℃ (high temperature type)

Process pressure: -0.1~4.0 MPa (flat flange) -0.1~0.3 MPa (universal flange)

Accuracy: ±15mm

Protection level: IP67

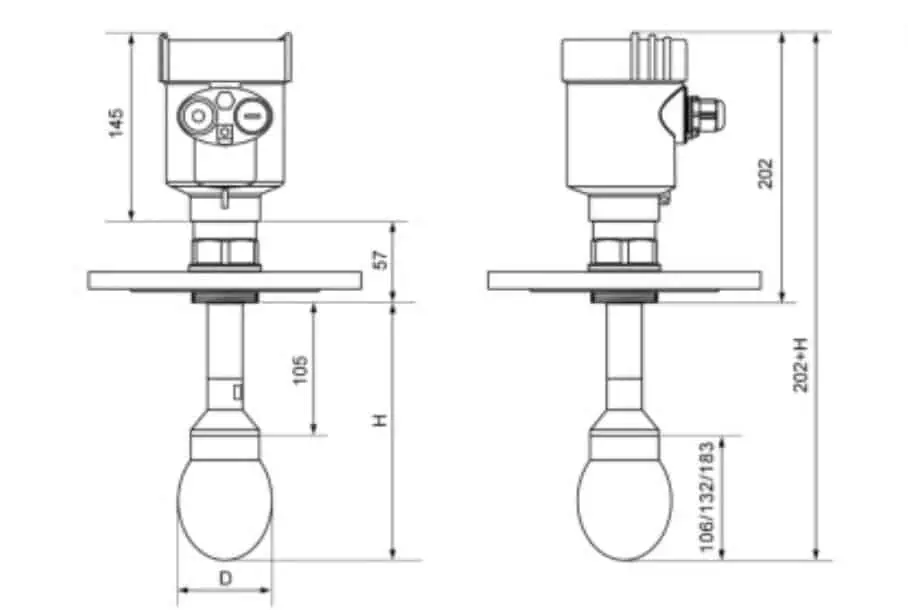

Measuring medium: liquid;

Measuring range: 0.05m~30m;

Process connection: G1½A / 1½NPT thread / flange ≥DN50;

Process temperature: -40~80℃;

Process pressure: -0.1~0.3 MPa;

Antenna size: 32mm lens antenna;

Antenna material: PTFE

Measuring medium: liquid

Measuring range: 0.1m~100m

Process connection: flange ≥DN80

Process temperature: -40~110℃

Process pressure: -0.1~0.3MPa

Antenna size: 78mm lens antenna

Antenna material: PTFE

Measuring medium: liquid and Solids

Measuring range: 0.1m~120m

Process connection: flange≥DN80

Process temperature: -40~200℃; -60~1200℃

Process pressure: -0.1~2.5MPa

Antenna size: 78mm lens antenna

Antenna material: PTFE/full filling

Measuring medium: solid

Measuring range: 0.3m~150m

Process connection: flange≥DN80

Process temperature: -40~110℃

Process pressure: -0.1~0.3MPa

Antenna size: 78mm lens antenna + purging (or without purging)

Antenna material: PTFE

Applicable medium: liquid, especially low-dielectric constant, slightly viscous, agitated liquid

Application: 20% flour slurry tank measurement; liquid measurement with stirring

Explosion-proof certification: Exia IIC T6 Ga/Exd IIC T6 Gb

Measuring range: 20m

Antenna: Horn antenna

Frequency: 6 GHz

Process temperature: -40~130℃(standard type)/-40~250℃(high temperature type)

Applicable medium: solid, especially medium measurement in high temperature environment

Application: Blast furnace level measurement

Explosion-proof certification: Exia IIC T6 Ga/Exd IIC T6 Gb

Measuring range: 15m

Antenna: Horn antenna

Frequency: 6 GHz

Process temperature: (-40~400)℃

Types of Radar Antennas

Radar level meters are tools that we use to measure the level of liquids, slurries, or granules without touching them. They’re pretty versatile and work well in places where temperatures and pressures change a lot, or where there are gases that don’t react to chemicals or things that can evaporate easily. They work using pulses of microwave radiation and can function in the range of usual industrial frequencies. Plus, they’re safe to use as they don’t emit a lot of energy and can be placed in all sorts of containers or pipes, whether they’re metal or not, without causing harm to people or the environment.

Now, there are a few types of antennas that these radar level meters can use:

- Rod Antennas: These are good for measuring things that can corrode over time. They can handle pressures up to 1.6MPa and temperatures up to 20°C. They have a wide angle of emission, around 30 degrees, which means their signal isn’t that strong and they’re not as accurate. But they’re easy to clean and often used in good conditions, for larger measures, and small ranges, like tanks and corrosive substances.

- Horn Antennas: These antennas have a large opening, which means they can receive and send signals well. They’re suitable for most measurements and can work under pressures up to 6.4MPa and high temperatures up to 350°C. They focus signals better and have a smaller angle of emission than rod antennas. So, if it’s a high-frequency radar level meter, the emission angle is even smaller, and the accuracy is higher. Many buffer tanks, storage tanks, and reaction tanks use this type of antenna. But they’re not good for corrosive substances.

- Parabolic Antennas: These are newer antennas often used in high-frequency radar. They have a very small emission angle, only 3.5 degrees, which makes them great for precise measurements and working around obstacles.

- Guided Wave Radar: This uses metal or cable to send and receive electromagnetic waves. It’s a contact measurement method, which means it touches what it’s measuring. It’s not much affected by dust, steam, or sticking to the waveguide rod, so it’s used a lot in solid level and small dielectric constant measurements.

- Waveguide Antennas: These should be chosen when the dielectric constant is small (1.6~3) or when there are continuous whirlpools on the liquid surface or false reflections caused by devices inside the container. They focus the radar waves and are installed in the waveguide or bypass pipe. The size of the waveguide’s inner diameter affects the time it takes for the radar waves to travel, so it should be set in the parameters to compensate for the travel time. This type of antenna requires the substance being measured to flow well and not to stick to the material.

How to Choose the Right Radar Antenna

Choosing the right radar antenna for a radar level meter might seem a bit tricky, but it can be a breeze if you know what to look for. Let’s go through the factors you need to think about:

- Size of the Tank: Bigger tanks need antennas that can handle longer distances. For example, horn antennas are great for bigger tanks because they have a large opening, so they can send and receive signals well.

- Substance Being Measured: Different substances need different types of antennas. If you’re measuring something corrosive, a rod antenna might be your best bet because it can handle corrosive substances. But, if you’re measuring something solid, you might want to go for a guided wave radar, as it’s not much affected by dust or sticking to the waveguide rod.

- Process Conditions: If the conditions in which you’re working have high pressures or temperatures, or if there are gases that don’t react to chemicals, you might need a more durable antenna, like a horn antenna. These can work under pressures up to 6.4MPa and high temperatures up to 350°C.

Now, here’s some advice on matching antenna types to specific needs:

- Rod Antennas: Choose these when you’re measuring corrosive substances, and your operating conditions are pretty stable. They’re also good for larger measures and small ranges.

- Horn Antennas: These are versatile and suitable for most measurements. They’re great for larger tanks and can handle high pressures and temperatures. However, avoid using them with corrosive substances.

- Parabolic Antennas: Go for these when you need precise measurements, especially in high-frequency radar. They’re also good at working around obstacles.

- Guided Wave Radar: This is your choice for solid level measurements or when the substance you’re measuring has a small dielectric constant.

- Waveguide Antennas: Opt for these when the substance you’re measuring flows well and won’t stick to the material. They’re good when the dielectric constant is small or when there are continuous whirlpools on the liquid surface.

Remember, the key is to understand your specific needs and conditions before making a decision. That way, you’ll pick the perfect radar antenna for your radar level meter.

FAQ

Extended Reading: Case: High Temperature Radar Level Transmitter for Melted Salt-Solar Photovoltaic Power Station

More Level Measurement Solutions

Shop Radar Level Sensors for Solids: 5 Must-Know Factors

Guided Wave Radar Level Transmitter Calibration and Troubleshooting

Stilling Wells for Radar Level Measurement|What Is It? Why Do You Need It?

Silo Radar Level Measurement | Why Do We Prefer Radar?

Crude Oil Measurement, 80G Radar Level Meter Should Be Your First Choice!

Influence of Dielectric Constant on Liquid Level Measurement | Radar-Guided Wave Radar Level Meter

So, there you have it! All you need to know about radar level meters and radar antennas. It’s important to choose the right antenna for your radar level meter, and we hope this guide has made that process a bit easier for you.

Remember, here at Sino-Inst, we’re not just experts, we’re also manufacturers and suppliers. We know our stuff, and we make quality products. And the best part? We offer customization to suit your specific needs. So why wait? Contact us today and get the perfect radar level meter for your needs.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.