Radar level gauges are an essential part of many industrial operations, serving as the invisible sentinels that accurately measure the levels of various substances. These sophisticated devices use cutting-edge radar technology to make precise, non-contact measurements. Capable of working seamlessly under a variety of challenging conditions, radar level gauges offer undeniable benefits in accuracy, reliability, and versatility.

Featured Radar Level Gauge Selection

- Measuring medium: Liquid

- Measuring range: 0.1m~10m

- Process connection: Thread G¾”A / ¾”NPT;Flange ≥DN25

- Process temperature: -40~100℃

- Process pressure: -0.1~1.6 MPa

- Antenna size: 21mm lens antenna

- Antenna material: PTFE

- Accuracy: ±5mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle:14°

- Power source:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol

- Measuring medium: Liquid

- Measuring range: 0.1m~30m

- Process connection: Thread G½”A /1 ½”NPT; Flange ≥DN40

- Process temperature: -40~80℃/ -40~100℃

- Process pressure: -0.1~0.3 MPa

- Antenna size:32mm lens antenna

- Antenna material: PTFE

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 8°

- Power source:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART protocol

- Measuring medium: Liquid

- Measuring range: 0.1m~30m

- Process connection:Flange ≥DN40

- Process temperature: -40~120℃

- Process pressure: -0.1~1.6 MPa

- Antenna size:32mm lens antenna

- Antenna material: PTFE

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 8°

- Power source:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART protocol

- Measuring medium: Liquid

- Measuring range: 0.2m~30m/0.3~150m

- Process connection:Flange ≥DN80 /Thread G3 A

- Process temperature:

- -40~150℃

- -40-130℃( Athread)

- Process pressure: -0.1~1.0 MPa

- Antenna size:76mm lens antenna

- Antenna material: PTFE

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 3°

- Power source:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol

- Measuring medium: Liquid

- Measuring range: 0.2m~30m/0.3~150m

- Process connection:Flange ≥DN80 /gantry frame

- Process temperature: -40~80℃

- Process pressure: -0.1~0.3 MPa

- Antenna size:76mm lens antenna

- Antenna material: PTFE

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 3°

- Power source:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol

- Measuring medium: Liquid

- Measuring range: 0.1m~30m/0.3m~150m

- Process connection:Flange ≥DN80

- Process temperature: -40~280℃

- Process pressure: -0.1~2.5 MPa

- Antenna size:76mm lens antenna

- Antenna material: PEEK

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 6°

- Power source:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol

- Measuring medium: Liquid

- Measuring range: 0.1m~30m

- Process connection:Flange ≥DN50

- Process temperature: -40~200℃

- Process pressure: -0.1~2.5 MPa

- Antenna size:44mm lens antenna

- Antenna material: PTFE

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 6°

- Power source:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol

- Measuring medium: Liquid

- Measuring range: 0.3m~30m

- Process connection:Flange ≥DN80

- Process temperature: -40~200℃

- Process pressure: -0.1~2.5 MPa

- Antenna size:76mm lens antenna

- Antenna material: PTFE

- Accuracy: ±2mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 3°

- Power source:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol

- Measuring medium: Solid

- Measuring range: 0.1m~30m/0.3~150m

- Process connection:Flange ≥DN80

- Process temperature: -40~150℃/-40~200℃

- Process pressure: -0.1~0.3 MPa

- Antenna size:76mm lens antenna

- Antenna material: PTFE

- Accuracy: ±5mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 3°

- Power source:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol

- Measuring medium: Solid

- Measuring range: 0.1m~30m/ 0.3m~150m

- Process connection:Flange ≥DN80

- Process temperature: -40~80℃

- Process pressure: -0.1~0.3 MPa

- Antenna size:76mm lens antenna

- Antenna material: PE

- Accuracy: ±5mm

- Protection level: IP67

- Center frequency: 80GHz

- Launch angle: 3°

- Power source:

- Two-wire system/DC24V

- Four-wire system/AC220V

- Six-wire system/DC12-24V

- Shell: Aluminum/Plastic/Stainless steel

- Signal output:

- Two-wire system/4…20mA/HART protocol

- Four-wire system/4…20mA/HART protocol

- Six-wire system/4…20mA/HART Protocol

Radar Level Gauges Measurement Technology

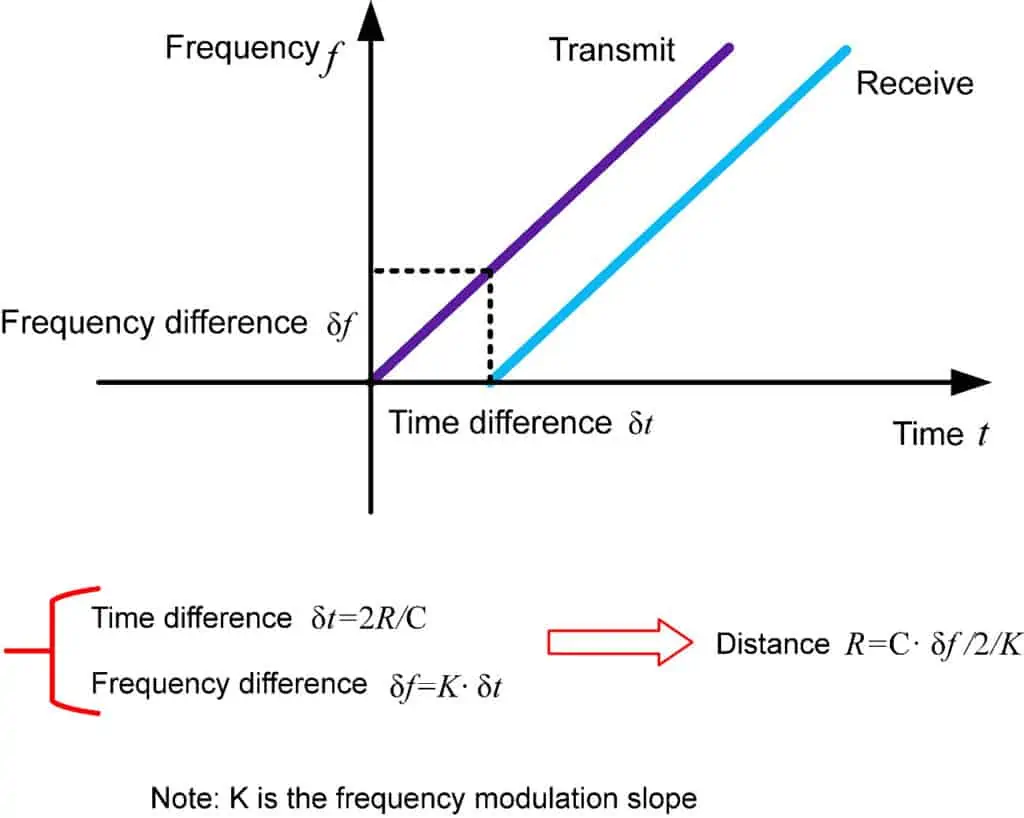

The general principle of the FM continuous wave radar level gauge is that the radar emits electromagnetic waves on the top of the tank, and the electromagnetic waves are received by the radar after being reflected by the medium.

The frequency difference δf between the received signal and the transmitted signal is proportional to the distance R from the surface of the medium: R=C (speed)*δf (frequency difference)/2/K (frequency modulation slope).

Because the speed of light C and the frequency modulation slope K are known, the frequency difference δf can be estimated to obtain the distance R from the radar installation position to the material surface. And then through the known total height of the tank, subtract the spatial distance from the radar to the material surface (referred to as Empty height) to get the height of the material level.

Advantages of Using Radar Level Gauges

- Millimeter-wave radar, with a measurement accuracy of up to ±1mm, and a minimum blind area of 0.1m.

- The smaller antenna size satisfies the measurement of more working conditions.

- A variety of lens antennas, smaller launch angle, more concentrated energy, stronger echo signal, under the same industrial and mining conditions, compared to

Other radar products have higher reliability. - With stronger penetrability, it can be used normally even if there is adhesion and condensation.

- The dynamic signal range is larger, and the measurement of low dielectric constant medium is more stable.

- 6. A variety of measurement modes, the radar reaction time in the fast measurement mode is less than 1S.

Applications of Radar Level Gauges Across Industries

Grain Bin Level Indicators: The Missing Piece in Your Grain Storage Solution

Radar Liquid Level Sensors

Radar Antenna Types for Radar Level Meters: How to Choose?

How to Choose the Right Diesel Fuel Level Sensor ?

Shop Radar Level Sensors for Solids: 5 Must-Know Factors

Stilling Wells for Radar Level Measurement|What Is It? Why Do You Need It?

Silo Radar Level Measurement | Why Do We Prefer Radar?

Crude Oil Measurement, 80G Radar Level Meter Should Be Your First Choice!

A New Choice for Boiler Drum Level Measurement – Guided Wave Radar

Selection List

When choosing a radar level gauge, several factors need careful consideration to ensure that the gauge suits your specific requirements. Here’s a list to guide your selection process:

Selecting the right radar sensor requires careful evaluation of your specific needs based on the sensor’s capabilities. Here we take the selection data of one of the radar level gauges FMW21/21s as an example.

| 21/21s |

| ID: |

| License |

| P Standard (Non-explosion-proof) I Intrinsically safe(Exia IIC T6 Ga) D Flameproof(Ex db IIC T6 Gb) |

| Process Connection / Material |

| 1 Flange≥DN80 X Special customization |

| Antenna Type / Material |

| A 76mm Lens antenna / With purge port / PE B 76mm Lens antenna / With purge port / PTFE |

| Sealing / process temperature |

| A FKM/(-40-80℃) B FKM/(-40-150℃) C FKM/(-40-200℃) Y Special customization |

| he Electronic Unit |

| 1 (4~20)mA/HART protocol 24VDC 2-wire 2 (4~20)mA/HART protocol 220VAC 4-wire 3 (4~20)mA+RS485/Modbus protocol 12- 24VDC 6-wire |

| Shell material/protection grade |

| A Cast aluminum / Single chamber / IP67 B Cast aluminum / Double chamber / IP67 C Cast aluminum / Double cavity side view / IP67 D Plastic ABS / Single chamber / IP65 E Stainless steel 304 / Single chamber / IP67 F Stainless steel 304 / Double chamber / IP67 |

| Cable Line |

| M M20×l. 5 N ½″ NPTX Special customization |

| Display programming |

| A Programming with display B With display programming/ Bluetooth communication C Without |

Flange option / material

| Specification / Code / Material | PP Universal | PTFE Universal | Stainless steel304 Universal | Stainless steel316L Universal |

| DN80 | P4 | F4 | G4 | S4 |

| DN100 | P5 | F5 | G5 | S5 |

| DN125 | P6 | F6 | G6 | S6 |

| DN150 | P7 | F7 | G7 | S7 |

| DN200 | P8 | F8 | G8 | S8 |

More Featured Radar Level Meters

FAQ

In conclusion, radar level gauges are a sophisticated and highly reliable tool for non-contact level measurement across diverse industries.

At Sino-Inst, we understand the vital role that accurate level measurement plays in your operations. We’re an experienced manufacturer and supplier of radar level gauges.

Whether you’re looking for standard options or require customized solutions to meet unique requirements, our team is ready to assist. We’re committed to delivering high-quality products that contribute to the efficiency and success of your business.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.