What is radar level transmitter frequency range? When purchasing radar level gauges, users often encounter different specifications and models. The most common are different measurement frequencies. Such as 8GMHz, 26GMHz, 80GMHz, 120GMHz, etc. All are radar gauges, why are the frequencies so different? What are the advantages and disadvantages of different frequency products? I hope that through the introduction of this article, you can choose a radar level gauge product suitable for measuring working conditions when purchasing a radar level gauge.

classification of radar level transmitter frequency range

The radar level Transmitter is a measuring instrument based on electromagnetic wave emission and reflection reception to judge the level of material. According to the type of transmitted signal, it is divided into two categories: pulse radar and frequency modulation continuous wave radar.

Pulse radar is measured based on time domain reflectometry (TDR). That is, the radar antenna emits high-frequency pulse electromagnetic waves, which propagate at the speed of light.

When encountering the surface of the measured medium, part of the pulse of the radar level Transmitter is reflected to form an echo back To the pulse emission device. The distance between the emission device and the surface of the measured medium is proportional to the propagation time of the pulse. The height of the liquid level is obtained by calculation.

Frequency modulation continuous wave radar is based on the frequency difference of frequency modulation continuous wave (FMCW). That is, the radar uses synchronous frequency modulation technology. The transmitter and receiver are installed on the top.

The transmitter emits a microwave signal whose frequency has been linearly modulated to the liquid surface. When the microwave When the signal propagates down to the liquid surface and is reflected back to the receiver. Due to the time delay, the frequency of the transmitted signal changes. The distance passed by the radar wave is calculated by the frequency difference between the received reflected wave and the transmitted wave.

Generally speaking, the larger the frequency modulation range, the longer the measurement distance, the better the linearity and the higher the resolution.

Microwave refers to electromagnetic waves with frequencies ranging from 300MHz to 3x103GHz, and their corresponding wavelengths range from 0.1mm to 1m. This segment of the electromagnetic spectrum includes decimeter waves (frequency range 300MHz~3GHz), centimeter waves (frequency range 3~30GHz), millimeter waves (frequency range 30~300GHz) and submillimeter waves (frequency range (300MHz~3x103GHz) ) four bands.

The common radars on the market are 6GHz, 26GHz and 80GHz that appeared in the last two years. The wavelength of the 6GHz radar is 50mm, and the wavelength of the 26GHz radar is 11mm, both of which are centimeter wave radars. They belong to microwave radars that work in the centimeter wave band for detection. The wavelength of the 80GHz radar is 4mm, which belongs to the millimeter wave radar working in the millimeter wave band.

Comparison of different frequency radar level transmitters

Extended Reading: Case: High Temperature Radar Level Transmitter for Melted Salt-Solar Photovoltaic Power Station

Effect of radar level transmitter frequency range on measurement

The radar level gauge emits electromagnetic waves through the antenna. The higher the frequency of the electromagnetic wave, the higher the energy of the electromagnetic wave. The shorter the wavelength, the more obvious the scattering phenomenon. Conversely, the lower the energy, the longer the wavelength, and the energy is not easily absorbed by the gas phase layer.

For the same size antenna, a liquid level sensor with a wavelength of 1.2 cm and a frequency of 26 GHZ has a gain of 6 times higher than that of a liquid level sensor with a wavelength of 3 cm and a frequency of 10 GHZ. (Remarks: Antenna gain is a parameter indicating the degree of radiation concentration of a directional antenna).

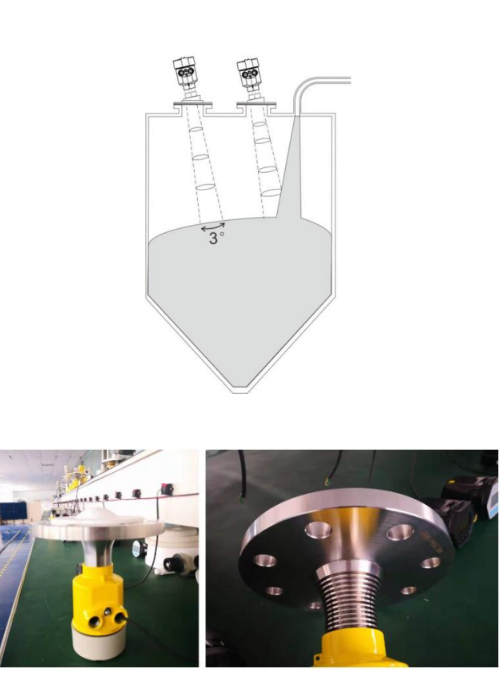

The overall beamwidth of a radar level gauge is inversely proportional to the frequency of the device. Therefore, for the same diameter antenna, if the frequency of the radar level gauge is increased, the beam width will be lower than that of the lower frequency equipment, and the narrow beam can minimize the influence of the nozzle, tank wall and interference.

At the same time, the measurement range of the radar level gauge is also affected by factors such as frequency, antenna size, dielectric constant of the liquid, and process conditions.

Featured Radar Level Transmitters

The difference in application of radar level transmitter frequency range

Dirty and polluted environment

With long-term use, dirt and pollutants accumulated on the antenna will affect the strength and direction of the radar signal. For high frequency signals, any dirt that covers the antenna will absorb more energy, and the direction of the beam may change. This results in a loss of signal strength. So, low-frequency and medium-frequency technologies are more suitable.

Storage tanks with condensate and/or steam

Condensation and steam can cause reflections on product surfaces to be masked by the “noise” of water droplets. This is more of a problem for high frequency signals. So mid and low frequency techniques are a better choice. Antennas with flat, horizontal surfaces should always be avoided for condensation.

High steam and agitation

Be sure to choose the 80G millimeter-wave radar level meter. The 80G radar level meter has a high transmission frequency and has good penetration and is not affected by steam. The 2° transmission angle can effectively avoid the interference of the stirring blade. The unique echo Tracking algorithm avoids reading multiple echoes when the material level is high.

Applications with turbulence, waves and ripples

Waves and ripples are often found on the surface of process liquids in large tanks. And this turbulence is especially detrimental to high-frequency measurements. Low and mid frequency level instruments emit longer wavelengths, making them perform better.

Foam application

Like dust and condensation, a layer of foam on top of the liquid can absorb the radar signal, making accurate measurements more difficult. Low frequencies work best with thick foams, such as beer, molasses, or latex. For lighter foam, the mids perform well. High frequency techniques should be avoided in foam applications.

Read more about: Stilling Wells for Radar Level Measurement

Bulk liquid storage tank

Many bulk storage tanks use floating roof tanks that require level measurement through stilling pipes. Low frequency radars are preferred for these applications as they are less sensitive to buildup on pipe walls. Except in not perfectly straight tanks and pipes. High frequency radars would have difficulty in this situation.

Small and medium container

These vessels are often up to 20 meters (m) high and often present challenging conditions. such as condensation, contamination, turbulence and foam. IF technology is a good choice in this tank because it combines small antennas with good reliability.

Small tank/bucket

In small tanks approximately 0.5 to 1.5 m high, the size and position of the nozzles may be restricted. Short measurement ranges and the need for small antennas mean that HF and MF technologies are attractive options for these applications.

For measuring the level of solids, the optimum frequency depends on the application. Low and mid frequencies can handle dust, condensation and coarse solids. High frequency is suitable for fine powder.

Condensation is often challenging for high-frequency radars. But with solids another problem arises: Condensation combined with certain types of solids can lead to rapid buildup of material. This quickly clogs the small nozzle opening and covers the small antenna of the high frequency radar.

Read more: The Impact of Frequency in Non-Contacting Radar Level Measurement by Emerson

More Level Measurement Solutions

Radar level gauge is favored by the majority of users because of its unique advantages. Whether it is toxic medium, corrosive medium or solid medium, it can withstand various harsh measurement conditions and maintain stable and reliable work. Liquid is still dust. Slurry material medium, can achieve stable and accurate measurement.

About What Is Radar Level Transmitter Frequency Range? I hope that through this article, you can have a detailed understanding. Frequency band selection is an important consideration when deciding which non-contact radar device is the best choice for each different level measurement application.

The difference in the application of radar level transmitter frequency range is summed up after our many years of experience.

When measuring steam and foam, and condensate, choose low-frequency radar first.

In most other applications, high frequency radars are preferred for ease of installation. Lower frequencies reduce sensitivity to vapor, foam and antenna contamination.

Low frequency radars have a wider beam velocity angle to better deal with steam, dust, condensation, contamination and turbulent surfaces.

Higher frequencies minimize the effect on nozzles, tank walls and disturbances.

If you need to choose radar level transmitter, or still have doubt about radar level transmitter frequency range. Please feel free to contact our sales engineers.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.