Sanitary Pressure Transmitter is also called a Hygienic pressure sensor or tri-clamp pressure transmitter. Sanitary Pressure Transmitter is used for food &beverage or pharmaceutical application.

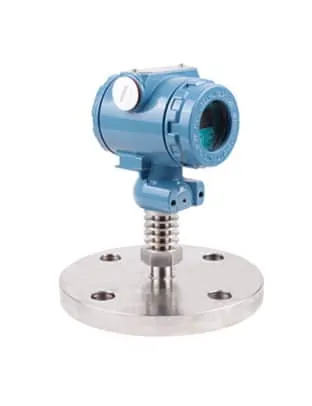

Sanitary Pressure Transmitter, also called tri-clamp pressure transmitter. It is the pressure transducer with the flush diaphragm (flat membrane) as the pressure sensor. Sanitary Pressure Transmitter uses a flat membrane to directly sense the pressure. The sensor interface is available in clamp type, M27 × 2, and flange type.

The sanitary pressure transmitter is designed especially for the requirements of the food and beverage, pharmaceutical and biotechnology industries.

It is particularly suitable for the special conditions of CIP/SIP cleaning processes. Such as chemical stability towards cleaning liquids and high temperatures

Sino-Inst offers a variety of Sanitary Pressure Transmitters for industrial pressure measurement. If you have any questions, please contact our sales engineers.

Features of Sanitary Pressure Transmitter

- Pressure interface with 316L flat diaphragm structure

- Hygienic, anti-fouling

- Wide measuring range for absolute pressure, gauge pressure and sealed reference pressure

- Good sealing and stable work for a long time

- With heat sink, high temperature media application performance

- Output signal can be selected, can be customized according to customer requirements

No Liquid Fill Diaphragm, Sanitary Clamp Fitting

The SI-350 sanitary pressure transmitter uses a flat membrane to directly sense the pressure signal. The diffused silicon pressure core acts as a sensitive component. Standard silicone oil is used as the pressure transmission medium.

The measuring end is made of 316L stainless steel and is specially welded and processed. Compact structure, corrosion resistance, vibration resistance, and wide temperature compensation.

SI-350 Sanitary Pressure Transmitter Type prevents fouling, unsanitary and sticky pressure blocking. Due to the pressure felt directly at the exposed end of the threaded diaphragm. It is particularly suitable for pressure measurement of viscous fluids with hygienic requirements in the medical and food industries.

Widely used in food, medicine, brewing, and other health industries. And stress tests that can scale the measurement medium.

Specifications of SI-350 Sanitary Pressure Transmitter

| Model | Description |

|---|---|

| 350-02 | Sanitary pressure transmitter, range 0- 10kPa, 300%FS overpressure, 2″ sanitary clamp connection. |

| 350-101 | Sanitary pressure transmitter, range 0- 20kPa, 300%FS overpressure, 1-1/2″ sanitary clamp connection. |

| 350-12 | Sanitary pressure transmitter, range 0- 400kPa, 200%FS overpressure, 2″ sanitary clamp connection. |

| 350-22 | Sanitary pressure transmitter, range 0- 600kPa, 200%FS overpressure, 2″ sanitary clamp connection. |

| 350-32 | Sanitary pressure transmitter, range 0-1MPa, 200%FS overpressure, 2″ sanitary clamp connection. |

| 350-42 | Sanitary pressure transmitter, range 0-1.6MPa, 200%FS overpressure, 2″ sanitary clamp connection. |

| 350-52 | Sanitary pressure transmitter, range 0-2.5MPa, 200%FS overpressure, 2″ sanitary clamp connection. |

| 350-62 | Sanitary pressure transmitter, range 0-6MPa, 150%FS overpressure, 2″ sanitary clamp connection. |

| 350-72 | Sanitary pressure transmitter, range 0-10MPa, 150%FS overpressure, 2″ sanitary clamp connection. |

| Range range | -100kPa…0~10kPa…10MPa |

| Pressure type | gauge pressure, absolute pressure, sealing pressure |

| Power output | 4 to 20 mA (12 to 30 VDC) 0 to 5V, 1 to 5V, 0.5 to 4.5V, 0 to 10V (12 to 24VDC) |

| Accuracy | 0.5% FS |

| Hysteresis and repeatability | 0.1%FS |

| Temperature drift | 1.5% FS (@-20 °C ~ 85 °C) |

| Response time | ≤ 1ms (up to 90% FS) |

| Service life | ≥10x 10^6 pressure cycle |

| Working temperature | -20 ° C ~ 85 ° C |

| Storage temperature | -40 ° C ~ 85 ° C |

| Medium temperature | -40~85°C (without heat sink) -40~150°C (three heat sinks), -40°C~250°C (five heat sinks) |

| Insulation resistance | ≥100MΩ/250VDC |

| Vibration resistance | Sinusoidal: 20g, 25Hz~2kHz; IEC 60068-2-6 Random: 7.5grms, 5Hz ~ 1kHz; IEC 60068-2-64 |

| Protection level | IP65 |

| Media compatible | with a variety of media compatible with 316L stainless steel |

| Explosion-proof grade | Intrinsically safe explosion-proof ExiaIICT6 |

Guess You’ll Like: Explosion Proof Pressure Transmitter

Applications of Sanitary Pressure Transmitter

Ideal for applications where sanitary conditions are of high priority (i.e. dairy, food processing, pharmaceutical, etc.)

Medical and health, food, wine, dairy, beverages, etc. thick and easy to block, high hygienic requirements, easy to clean occasions.

Environmentally friendly chemical coatings, polyurethane equipment, paint inspection systems, etc.

Extended reading: Vortex Hygienic Flow Meter

- Sanitary process applications

- Food and beverage processing

- Water processing

- Dairy processing

- Pharmaceutical processing

Extended reading: Food grade flow meters for Food & Beverage industry

Drawing of SI-350 Sanitary Pressure Transmitter

Read more about: What is industrial pressure transmitter?

More Featured Pressure Transmitters

When the process medium should not come into contact with the pressured parts of the measuring instrument. Diaphragm sealed pressure transmitters are used.

Low pressure transducers for air and non-corrosive gases low pressure measurement. 0 ~ 2.5kPa to 0 ~ 30kPa measurable.

Flush membrane / diaphragm structure, anti-blocking design. Pressure measurement of viscous media.

Liquid pressure sensor is widely used for pressure measurement of various liquids. Like water or oils. IP68 waterproof.

Gas pressure sensor for industrial gas pressure monitoring. Pagoda gas nozzle Φ8. Such sensors are also commonly referred to as wind pressure transmitters, exhaust pressure sensors.

High pressure sensor is pressure transmitter designed for high pressure measure&control. 0 ~ 40MPa… 600MPa. M20 × 1.5, G1 / 2 (others are customized according to requirements)

Pressure sensor for Ultra high pressure applications. Ultra high pressures up to 15,00MPa. 0-2000MPa to 0-7000MPa (customized).Ball head M20 × 1.5, cone head M20 × 1.5.

High-temperature pressure transmitters with a 4-20mA output.

which has a temperature capability of over 850 °C and is not pyroelectric.

Technical Support

Flush diaphragm pressure transducer

Flush diaphragm pressure sensor uses a diaphragm isolation process. Feel the pressure directly with a flat membrane. There is no pressure hole in the test head. There is no clogging of viscous media during the measurement. Adopting flush membrane structure, diffused silicon pressure-sensitive core body, with good moisture resistance and excellent media compatibility. The sensor interface is available in clamp, thread and flange options. The output signal can be selected from voltage, current, and so on. The flush diaphragm of the sensor prevents problems such as scaling, unsanitary and clogging of viscous liquids.

Steam pressure transmitter

High Temperature Pressure Transducer/Transmitter works for steam and fluid. Temperature: -30 ℃ ~ 160-350 ℃, customized up to 850 ° C. It is possible to fit a stand off pipe, pigtail or other cooling device to reduce the media temperature. If not, High Temperature Pressure Transducer/Transmitter is the best choice. The pressure is transmitted to the sensor through the heat dissipation structure on the transmitter. The high-precision signal processing circuit is located in the stainless steel housing. The sensor output signal is converted to standard output signal, like 4-20mA.

High pressure transducer

The sino-Inst high-pressure transducer has gone through thousands of fatigue impact tests and several days of low and medium temperature aging cycles before leaving the factory. It has solved the disadvantages of high-pressure sensors in terms of stress and zero instability. Provide customers with reliable products for high voltage measurement. The pressure of the SI-702 series can reach 600MPa. The precision level is high, and the mature production technology can ensure the long-term stability of the sensor with excellent characteristics. SI-702 series pressure sensors are suitable for oil extraction platforms, water flow equipment, high-pressure measurement equipment, hydraulic control systems, test benches, and industrial automation control.

Pressure Transducer 4-20mA/Voltage

The signal system of 4-20mA and 1-5V output by the pressure transmitter is stipulated by international standards.In the signal circuit, the pressure transmitter is equivalent to a variable resistor. It is connected in series with the power supply, ammeter (indicator), and load resistance (including wire resistance). The function of the pressure transmitter is to change the current in the circuit in the range of 4-20mA by changing its own resistance according to requirements.The pressure acts on the sensor, and the sensitive element deforms. The deformation will cause the resistance or capacitance value to change. And then it will be converted into an analog 4-20mA output by the conversion circuit.

Other Sanitary Instruments

Sanitary Bimetal Thermometers also called the sanitary thermometer, or tri-clamp thermometer.

Sino-Instrument’s Sanitary Bimetal Thermometers are specially designed for direct insertion into sanitary process applications when a standard thermowell is not specified, or the process environment is not exposed to pressure.

Sanitary Flow Meter, also called sanitary turbine flow meter or Hygienic turbine flowmeter.

The Sino-Instrument sanitary turbine flow meter, food grade flow meter, provides accuracy, versatility, and economy, in measuring a wide variety of food, beverage and pharmaceutical products.

All of Sino-Inst pressure transmitters can work with the AMS TREX!

FAQ

What is pressure transmitter how it works?

Pressure Transmitters are sensors with electrical transmission output for remote indication of pressure. Process transmitters differentiate themselves from pressure sensors through their increased range of functionality. They feature integrated displays, offer high measuring accuracies and freely scalable measuring ranges. Communication is via digital signals, and waterproof and explosion-proof certifications are available. Through connection to diaphragm seals, they are suitable for the harshest operating conditions. Ideal for OEMs, process applications, water processing, and industrial pressure applications.

What is the input of the pressure transmitter?

A pressure transmitter is an instrument that converts pressure variables into a standardized output signal that can be transmitted. And there is a given continuous function relationship between the output signal and the pressure variable (usually a linear function). Mainly used for measurement and control of industrial engineering pressure parameters. Differential pressure transmitters are often used for flow measurement.

There are two types of pressure transmitters, electric and pneumatic. The electric standardized output signals are mainly 0mA ~ 10mA and 4mA ~ 20mA (or 1V ~ 5V) DC signals.

How do you calibrate a pressure transmitter?

If the transmitter is used for a period of time, it may cause a change in metering performance. There will be zero drift and increased measurement error. Therefore, it is necessary to perform regular calibration. The accuracy of the calibrator used for calibration should be more than 3 times the required calibration accuracy. Use the pressure calibrator to input the standard pressure values of 0%, 25%, 50%, 75%, and 100% of the range to the transmitter in the forward and reverse directions. Check whether the current output signal is within the allowable accuracy range. If it is out of tolerance, it needs to be adjusted. The adjustment method is as follows (4 ~ 20mA output):

(1) Input a standard pressure of 4mA with a pressure calibrator. Adjust the ZERO (zero) potentiometer. Make the 4mA current output within the accuracy range.

(2) Input a standard pressure of 20mA with a pressure calibrator. Adjust the SPAN (range) potentiometer. Make the 20mA current output within the accuracy range.

(3) ZERO and SPAN will contain each other. Repeat steps (1) (2) until the current output of 4mA point and 20mA point meets the accuracy requirements at the same time. Then check whether the current output of the 25%, 50%, 75% range points meets the accuracy requirements. The transmitter is qualified if it meets the requirements.

What are the types of pressure transmitters?

There are different types of pressure transducers based on their design.

These sensors can come in several shapes and sizes,

but the technology inside can also differ.

There 4 main types of pressure sensors based on this:

Strain Gauge Pressure Transducers

Capacitance Pressure Transducers

Potentiometric Pressure Transducers

Resonant Wire Pressure Transducers

More about Industrial Pressure Sensors

Sino-Instrument offers over 10 Sanitary Pressure Transmitters.

About 50% of these are 4-20ma pressure transmitters, 40% are Differential Pressure Gauge. And 20% are Diaphragm Seal Pressure transmitters. 20% are 4-20ma pressure transducer wiring diagrams.

A wide variety of Sanitary Pressure Transmitter options are available to you, such as free samples, paid samples.

Sino-Instrument is a globally recognized supplier and manufacturer of Sanitary Pressure Transmitters, located in China.

The top supplying country is China (Mainland), which supply 100% of Sanitary Pressure Transmitters respectively.

Sino-Instrument sells through a mature distribution network that reaches all 50 states and 30 countries worldwide.

Sanitary Pressure Transmitter products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, with ISO9001, ISO14001 certification.

Request a Quote

SI2088-W Wireless Pressure Transmitter SI-390 Industrial Pressure Transmitter SI-10 Liquid pressure sensor SI-D100 Diaphragm pressure gauge Submersible Pressure Transmitter HART pressure transmitters SI1151GP Gauge Pressure Transmitter Liquid Turbine Flow Meters Magnetic Flow Meters Orifice flow meter Oem smart Pressure Transducer pressure sensor SMT3151LT Pressure Level Transmitter

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.