Orifice plate flow meter also called orifice flow meter or orifice plate. Orifice plate flow meter is a kind of differential pressure flow meter.

Orifice plate flow meter works together with an orifice plate, differential pressure transmitter, with Differential Pressure Measurement principle. Easy installation. Orifice plate flow meters can be used with gases, liquids, corrosive, and high temperature fluids. Orifice flow meters can measure steam, gas, liquids, and many industrial areas. Applications include steam flow, boiler feedwater, and fluid flow rates in building water lines.

Sino-Inst, Manufacturer for differential pressure flow meters. Including the Orifice plate, Venturi, Annubar, etc. Suitable for liquid, gas, and steam flow measurement. Please contact our sales engineers for technical support!

Features of Orifice Plate Flow Meter

- The structure of the throttling device is easy to copy, simple, firm, stable and reliable in performance, long in service life, and low in price.

- Orifice flowmeter calculation adopts international standards and processing

- Wide application range, all single-phase flows can be measured, and some mixed-phase flows can also be applied.

- The standard throttling device can be put into use without real flow calibration.

- The integrated orifice plate is simpler to install, no pressure pipe is needed, and it can be directly connected to a differential pressure transmitter and a pressure transmitter.

- It has a wide range of applications, including all single-phase fluids (liquid, gas, steam) and partial mixed-phase flows. The pipe diameter and working conditions (temperature, pressure) of the general production process can be measured;

Orifice Plate Flow Meter Specification

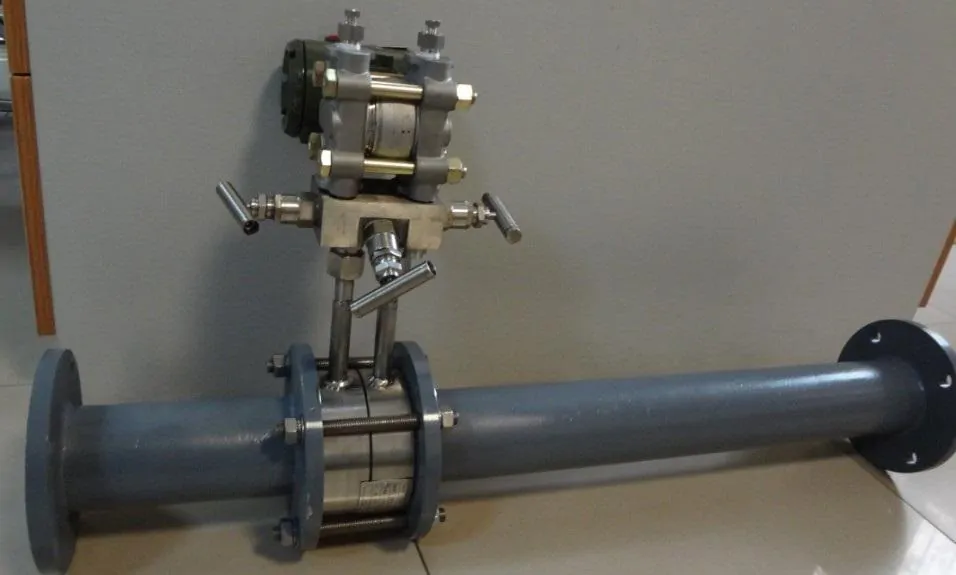

SI-LG integrated orifice flowmeter is a high-range ratio differential pressure flow device. Composed of standard orifice plate and multi-parameter differential pressure transmitter (or differential pressure transmitter, temperature transmitter and pressure transmitter).

It can measure the flow of gas, steam, liquid and natural gas, and is widely used in process control and measurement in petroleum, chemical, metallurgy, electric power, heating, water supply, and other fields.

| Execution standard | Design, manufacture, and installation in accordance with international standard ISO5167-1(1991)(national standard GB/T2624-93), British standard BS1042 and other standards |

| Precision level | (1)Standard orifice plate, standard nozzle: there are many factors that affect the measurement error. If the installation and use meet the relevant provisions of international standard ISO5167-1 (1991), the accuracy level can generally reach level 1 ~1.5. (2) For non-standard orifice plates (such as double orifice plates, circular missing orifice plates, small orifice plates, etc.). Due to insufficient test data, there is no “standard” to check, so calibration should be conducted after the design and manufacture is completed. (liquid flow is usually calibrated with water. And the air calibrates the gas flow. The level of accuracy (basic error) can be achieved after calibration: level 1 ~1.5, if not calibrated. Only by empirical data calculation, design, accuracy in ±2.5%. |

| Diameter(mm) | 25,40,50,65,80,100,125,300,350,400, 450,500,600,700,800,900,1000,1200 |

| Nominal working pressure(MPa) | 0.6,1.0,1.6,2.5,4.0,6.3,10.0,16.0, ≤40Mpa. (when ≥20Mpa ,it can use high pressure lens orifice plate or welding type) |

| Conditions of use | The environment temperature:-30ºC~60ºC |

| Medium temperature: | -30ºC~550ºC |

| Working power supply | 24VDC/220VAC |

| Singal remote output | 4~20mA |

| Communication output | RS485 communication(Modbus-RTU); Hart protocol |

| Signal interface | Internal thread M20*1.5 (NPT1/2 needs to be customized, long delivery time) |

| Protection level | IP65 (customized IP68 for basic model) |

| Explosion-proof level | ExdIICT6 GB |

| Display | Differential pressure, instantaneous flow, cumulative flow |

Orifice Plate Types

Sino-Inst supplies all kinds of the orifice plate, for differential applications.

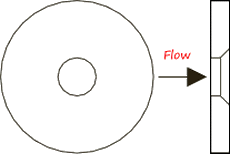

SQUARE EDGE (STANDARD) BORE

For the common square edge concentric bore orifice, the bore and bevel is the standard method of limiting the plate edge thickness.

Unless otherwise specified, plates will be beveled to the currently accepted standards.

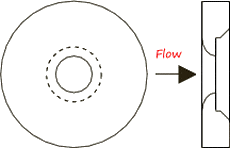

QUADRANT EDGE BORE

The quadrant edge bore is an orifice with the inlet edge rounded. Instead of beveling, the plate is counterbored to the desired edge thickness.

The radius of the quarter circle bore is a function of the orifice-to-pipe ratio (d/D). Thickness at the throat is equal to the radius.

This bore is specifically designed for viscous fluids such as heavy crudes, syrups, and slurries with Reynolds Numbers below 100,000.

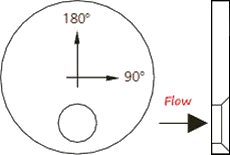

ECCENTRIC BORE

Eccentrically bored orifice plates are plates, with the orifice off-center, or eccentric, as opposed to concentric.

The bore of the eccentric orifice normally is inscribed in a circle, which is 98% of the pipe diameter, so that solids or slurries may pass through.

Eccentric orifice plates are used in many industries, including heavy and light chemicals, steel, paper, nuclear and petrochemicals.

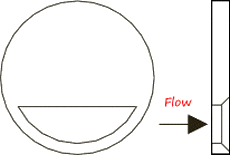

SEGMENTAL BORE

Segmentally bored orifice plates are provided for measurement, where solids are entrained in a gas or liquid flow stream.

The circular portion of the bore is inscribed within a circle, which is normally 98% of the pipe diameter.

The segmental opening may be placed either at the top or bottom of the pipe.

Industries using these bores include sewage treatment, steel, chemical, water conditioning, paper, and petrochemical.

RTJ Type Orifice Plates

The RTJ type orifice plate incorporates an integral gasket, either oval or octagonal ring, for mounting between ring type joint flanges.

It is based on proven technology, has no moving parts and is suitable for high temperature and pressure applications.

RTJ type orifice plates can be supplied complete with ANSI B16.36 orifice flanges.

Extended reading: Integral DP Flow Meter|Gas, liquid, steam|Compact structure

Orifice plates are recommended for clean liquids, gases, and low-velocity stream flows.

Plate thicknesses depend on line size and differential pressure and should be sufficient, to prevent the plate from bending under operating conditions. Orifice plates can be made in accordance with customer drawings as required.

If you still have questions about orifice plate flow meters, Just contact us. Our engineers will offer help.

Advantages of Orifice Plate Flow Meter

- The Orifice meter is very cheap as compared to other types of flow meters.

- Less space is required to Install and hence ideal for space-constrained applications

- The operational response can be designed with perfection.

- Installation direction possibilities: Vertical / Horizontal / Inclined.

Orifice Flow Meter Applications

- Natural Gas

- Water Treatment Plants

- Oil Filtration Plants

- Petrochemicals and Refineries

Of course, in the water supply or wastewater treatment industry, in addition to orifice flowmeters, electromagnetic flowmeters are also the first consideration for many users in the measurement of water flow.

For example, if you need to measure the flow of wastewater in a 2-inch pipe. Then you may refer to: Magnetic Flow Meters Guides.

How much is a 2 inch water flow meter? Let’s find out.

Orifice Plate Flow Meter Installation

Orifice plate installation

Orifice plate installation

1. Meter manifold piping should always be installed to enable calibration as well as to protect the differential element against overage.

2. The meter should be installed as close as possible to the orifice fitting.

3. Always slope the manifold lines gently from the orifice fitting to the meter to eliminate any high or low points in the manifold lines.

4. Use condensate chambers or air traps to remove either liquid from a gas system or gas from a liquid system if lows or highs in the manifold piping cannot be avoided.

It is important when pressurizing or depressurizing differential measuring devices to apply or release pressure to or from the high and low meter chambers uniformly, so as not to impose excessive overage.

What is an Orifice Meter?

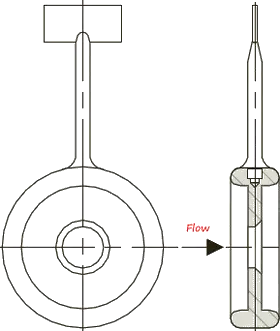

An orifice meter is a conduit and a restriction to create a pressure drop.

An hourglass is a form of the orifice.

A nozzle, venturi or thin sharp-edged orifice can be used as the flow restriction.

In order to use any of these devices for measurement, it is necessary to empirically calibrate them.

That is, pass a known volume through the meter and note the reading in order to provide a standard for measuring other quantities.

Due to the ease of duplicating and the simple construction, the thin sharp-edged orifice has been adopted as a standard and extensive calibration work has been done, so that it is widely accepted as a standard means of measuring fluids.

Provided the standard mechanics of construction are followed no further calibration is required.

The minimum cross-sectional area of the jet is known as the “vena contract”.

How does an orifice flow meter work?

I guess most people wondered: What is the working principle of orifice meter?

As the fluid approaches the orifice the pressure increases slightly and then drops suddenly as the orifice is passed.

It continues to drop until the “vena contract” is reached, and then gradually increases, until at approximately 5 to 8 diameters downstream, a maximum pressure point is reached, that will be lower than the pressure upstream of the orifice.

The decrease in pressure as the fluid passes thru the orifice, is a result of the increased velocity of the gas passing thru the reduced area of the orifice.

When the velocity decreases as the fluid leaves the orifice the pressure increases, and tends to return to its original level (To level transmitters).

All the pressure loss is not recovered because of friction, and turbulence losses in the stream.

The pressure drop across the orifice increases when the rate of flow increases.

When there is no flow there is no differential.

The differential pressure is proportional to the square of the velocity, it thus follows that if all other factors remain constant, then the differential is proportional to the square of the rate of flow.

Video source: https://www.youtube.com/embed/oUd4WxjoHKY?rel=0

Equations used in this orifice plate Calculator

Qv = 218.527*Cd*Ev*Y1*(d2 )*[Tb/Pb]*[(Pf1*Zb*hw)/(Gr*Zf1*Tf)]0.5 (3-6)

Where

Cd = Orifice plate coefficient of discharge

d = Orifice plate bore diameter calculated at flowing temperature (Tf) – in.

Gr = Real gas relative density (specify gravity)

hw = Orifice differential pressure in inches of water at 60 degF

Ev = Velocity of approach factor

Pb = Base pressure – psia

Pf1 = Flowing pressure (upstream tap – psia

Qv = Standard volume flow rate – SCF/hr.

Tb = Base temperature – degR

Tf = Flowing temperature – degR

Y2 = Expansion factor (downstream tap)

Zb = Compressibility at base conditions (Pb,Tb)

Zf1 = Compressibility (upstream flowing conditions – Pf1, Tf)

Orifice Plate Flow Meter Calculation

Converters for conversion and calculation of flow. Or a calculation tool that requires flow measurement to obtain other measurement parameters. Help users choose the right flow sensor and transmitter!

Venturi Flow Meter

Venturi flow meter is also called classical venturi, and is used to call venturi meter, standard venturi. It is used to measure the flow of single-phase stable fluid in closed pipelines.

Venturi flow meter is a flow measurement method based on the principle of differential pressure. Commonly used to measure the flow of fluids such as air, natural gas, coal gas, and water. In the standard throttling device, the upstream and downstream straight pipe sections required by it are short. The lasting pressure loss is small, the performance is stable, and the maintenance is convenient.

What is the difference between Venturimeter and orifice meter?

The difference between venturi flowmeter and orifice flowmeter:

Orifice flow meters and Venturi flow meters are very different in many aspects.

In order to reduce the loss of the kinetic energy of the fluid mechanics flowing through the saving components, the Venturi flowmeter uses each section of tapered and divergent tubes to replace the orifice.

The orifice flowmeter is equipped with an interchangeable orifice plate with a small circular hole on the upper side, which is much smaller than the diameter of the pipe. The orifice plate is placed on the side of the fluid mechanics pipe.

More about: Venturi Tube Flowmeter

1.The orifice flowmeter is similar to the Venturi flowmeter in the working principle. But some of the main differences are: the orifice plate can be easily replaced to accommodate a wide range of different flow rates.

The throat diameter of the venturi is fixed, so that the measured flow rate range is limited by the actual pressure difference.

Due to the vortex on the downstream side of the orifice, the permanent loss of the orifice flowmeter is very large.

The structure and shape of the Venturi flowmeter can avoid the formation of vortices, which can greatly reduce permanent losses.

2.The energy loss of Venturi flowmeter in measuring flow is much smaller than that of orifice flowmeter.

However, because the venturi flowmeter is more time-consuming in manufacturing and processing than the orifice flowmeter, and the price is high, the orifice flowmeter has the least trouble and the lowest cost during pipeline installation.

3.In terms of fluid measurement, Venturi flowmeters are generally used for low-velocity gas flow measurement.

The flow coefficient of the orifice plate in the orifice flowmeter is significantly affected by the fluid disturbance, and this disturbance comes from the influence of the valves, elbows and other pipe fittings installed upstream of the orifice plate. The value of its discharge coefficient is less affected by downstream disturbances. Generally, this kind of flowmeter should be installed at a distance of 50 times and 10 times the pipe diameter from the upstream and downstream disturbance components, respectively. Obviously the required distance is related to the nature of the disturbance.

Therefore, when measuring with an orifice flowmeter, the orifice flowmeter must be installed correctly according to the disturbance of the fluid.

The above is a detailed introduction to the question of “What is the difference between a venturi flowmeter and an orifice flowmeter”, I hope to help everyone.

If you have any other questions about this issue, please click Online Consultation and consult online customer service.

Extended reading: Flow Nozzle for Steam Flow Measurement

Frequently

Asked

Questions

More Featured Products

Related Blogs

Sino-Inst offers 12 orifice plate flow meter products. About 90% of these are flow meters.

A wide variety of orifice flow meter options are available to you, such as brass, carbon steel. You can also choose from free samples.

Sino-Inst is an orifice plate flow meter supplier. Orifice plate flow meter products are most popular in Domestic Market, Southeast Asia, and Mid East.

You can ensure product safety by selecting from certified suppliers, including 375 with ISO9001, ISO14001, and Other certification.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.