Sanitary Flow Meter, also called sanitary turbine flow meter or Hygienic turbine flowmeter. Ensure Accurate Flow Measurement in Sanitary food-processing and bio-technology industries.

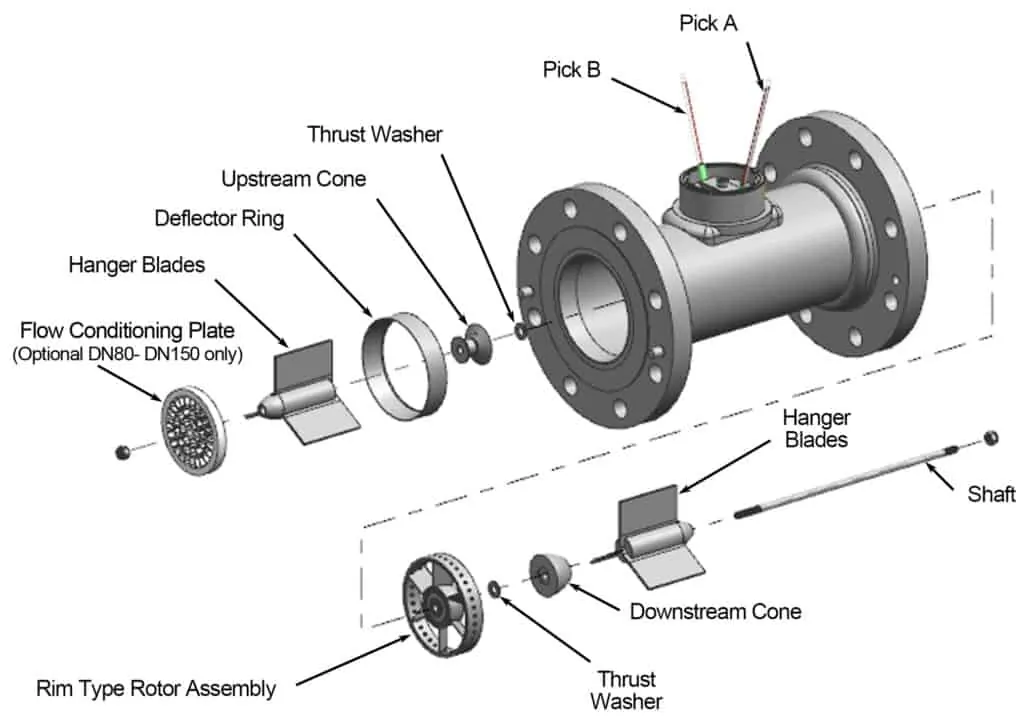

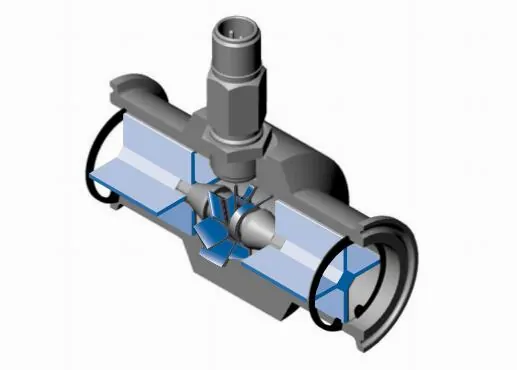

Sanitary turbine flow meters have stainless steel bodies and come standard with Tri-Clover fittings. Sanitary flow meter is suitable for measuring liquid without impurities. It can output pulse frequency signal. It is used to detect instantaneous flow and total integrated flow. Sanitary flow meter can be used in food, sport drink, liquor and other beverage industries, in preprocess applications.

Sanitary Turbine Flow Meter reference price: DN100. USD 300-700/pc.

Sino-Inst offers a variety of Turbine flow meters for flow measurement. If you have any questions, please contact our sales engineers.

Features of Turbine Sanitary flow meter

- Meets the requirements of 3-A Sanitary Standard number 28-04

- 316L stainless steel body and internal wetted parts

- Consistent, reliable gas flow measurement

- Wafer mounting configuration for limited space requirements

- Anti-corrosion and anti-rust materials, suitable for the health industry;

- Quick-load structure, easy to install and maintain;

- High precision and good repeatability;

- High-quality turbine, beyond the conventional range;

Benefits of sanitary turbine flow meter

The lightweight, balanced rotor provides instantaneous response to changes in the flow;

No mating flange design allows for quick and easy install;

Superior material of construction for high performance in aggressive environments.

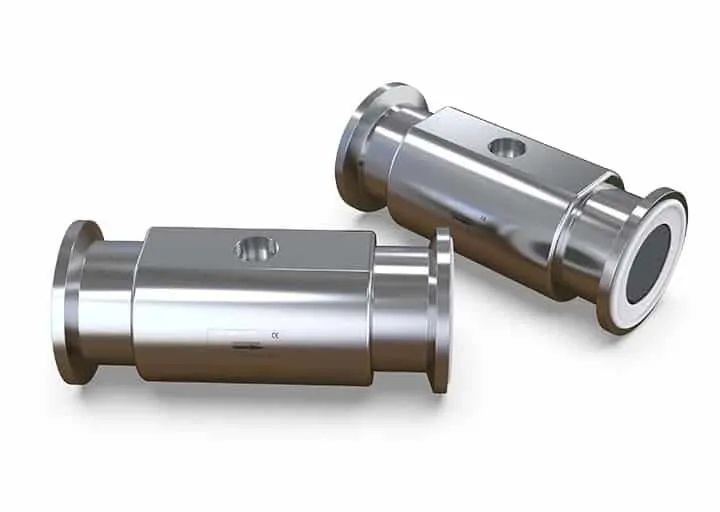

The SI-LWGY Series Sanitary Turbine Flowmeters feature 316 stainless steel construction. And have a smooth finish. Which is designed to eliminate cracks and crevices where bacteria breed.

Standard flowmeters are available in sizes from 1/2″ to 2″ with sanitary clamps.

Flow rates range from 0.1 to 250 gallons per minute (0.38 to 946 LPM).

Extended reading: Food grade flow meters for Food & Beverage industry

Specifications of Hygienic turbine flowmeter.

| Measuring range | 0.04-40m³/h |

| Applicable medium | Clean liquid without impurities (water, water solution, beer beverage, glycerin, glycol) |

| Nominal pipe diameter | DN4-50mm |

| Accuracy level | ±0.2%FS, ±0.5%FS, ±1.0%FS, ±1.5%FS |

| Repeatability error | ±0.5% of measured value; ±1.0% |

| Linearity | 1% |

| display | Wide screen LCD display, parameters and variables can be set through the buttons on the panel Instantaneous flow display, cumulative total display, percentage display, frequency display l/min, m³/h, Hz |

| Resolution | 0.1 l/min, 0.005 m³/h |

| Operating temperature | -35-60℃ (standard type) -20-180℃ (high temperature type) -40-80℃ (explosion-proof type) |

| Allowable viscosity | 0.8-30cm²/s |

| Work pressure | 1.6MPa, 2.5MPa, 4.0MPa, special can be customized |

| shell material | Stainless steel 316L |

| Turbine material | Stainless steel 316L |

| Head material | Aluminum alloy |

| Bearing | Tungsten carbide bearings, ruby bearings are optional |

| Entrance: 10*DN Exit: 5*DN | |

| Signal output | 4~20mA, pulse, RS485, MODBUS protocol, HART output |

| Power supply | 220V AC, 24V DC |

| Electrical connections | Intelligent type: M20*1.5 terminal wiring, Digital display type: aviation plug wiring Ordinary type: direct outlet |

| Connection method | Chuck |

| Protection level | IP65 (optional IP68) |

| Ambient temperature | -20℃…80℃ |

| Relative humidity | 5%~95% |

| Explosion-proof mark | Intrinsically safe ExiaIICT6 |

| Power consumption | <20W |

| Diameter(mm) | Normal flow range(m3/h) | Extended flow range(m3/h) | Regular pressure(MPa) |

| DN 4 | 0.04~0.25 | 0.04~0.4 | 1 |

| DN 6 | 0.1~0.6 | 0.06~0.6 | 1 |

| DN 10 | 0.2~1.2 | 0.15~1.5 | 1 |

| DN 15 | 0.6~6 | 0.4~8 | 1 |

| DN 20 | 0.8~8 | 0.45~9 | 1 |

| DN 25 | 1~10 | 0.5~10 | 1 |

| DN 32 | 1.5~15 | 0.8~15 | 1 |

| DN 40 | 2~20 | 1~20 | 1 |

| DN 50 | 4~40 | 2~40 | 1 |

Extended reading: Vortex Hygienic Flow Meter

SI-LWGY Sanitary flow meter applications

Typical applications include measuring or batch controlling water, WFI, USP water, deionized water, vaccines, clean pharmaceuticals, milk, cream, vegetable oil, wine, beer, spirits, soft drinks, juices (without pulp)and any other clean, consumable liquid.

Application Examples:

- Sanitary

- Food Processing

- Pharmaceutical

- Industries Process or Industrial

- Pharmaceutical industry:

- filling and metering of infusion products such as saline and glucose water;

- Food and beverage industry:

- filling and metering of liquid foods such as vegetable juice, juice, beer, and refined oil.

Extended reading: Turbine Insertion Flow Meter for Large Diameter Pipeline

Magnetic Sanitary Flow Meter

Magnetic Sanitary Flow Meter measures the flow of conductive liquids.

Sanitary Flow Meter uses a new type of sanitary lining material and lining technology, which meets the sanitary requirements of the food industry. It uses a stainless steel shell and stainless steel clamp connection. It is convenient for the quick disassembly and cleaning of the electromagnetic flow meter. Magnetic flow meter in a sanitary version which meets the strict requirements of the food-processing and bio-technology/ pharmaceutical industries.

Clamp on ultrasonic flow meter is also a good choice for the health industry. Because the external clamp sensor does not need to destroy the pipe.

Read more about: Sanitary Flow Meters-316SS,Tri clamp-Pulse- for Brewery

More about Turbine Flow Meters

Sino-Inst, Manufacuturer for Turbine Sanitary flow meterrs, like: gas turbine flow meter, liquid turbine flow meter, sanitary turbine flow meter, insertion turbine flow meter, steam turbine flow meter, and natural gas turbine flow meter.

Sino-Inst’s Turbine Sanitary flow meters, made in China, Having good Quality, With better price. Our flow measurement instruments are widely used in China, India, Pakistan, US, and other countries.

Request a Quote

Wu Peng, born in 1980, is a highly respected and accomplished male engineer with extensive experience in the field of automation. With over 20 years of industry experience, Wu has made significant contributions to both academia and engineering projects.

Throughout his career, Wu Peng has participated in numerous national and international engineering projects. Some of his most notable projects include the development of an intelligent control system for oil refineries, the design of a cutting-edge distributed control system for petrochemical plants, and the optimization of control algorithms for natural gas pipelines.